-

Title (Dublin Core)

-

Improvements in the Pilots' Equipment

-

Article Title and/or Image Caption (Dublin Core)

-

Something New in Fashions

-

extracted text (Extract Text)

-

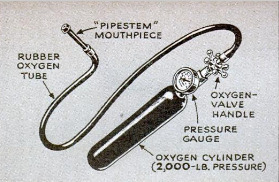

YEARS ago, our Army developed the first

aerial oxygen equipment, along with its

first high-altitude planes. This “free-flow”

system worked well enough in the earlier

days of military flying; the oxygen was fed

from the regulator into the mask, and the

pilot turned a handle to increase the flow as

he gained altitude,

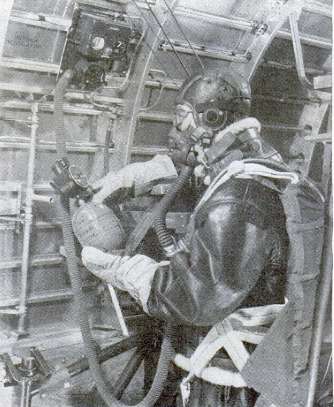

But in a modern warplane, under combat

conditions, flyers have too much else to do.

That's why the Aero-Medical Laboratory at

‘Wright Field was set the task of designing

oxygen equipment that would “do its own

thinking.” The solution they have come

through with is a honey—the best oxygen

system in the world, according to the Air

Surgeon General, whose business it is to

know.

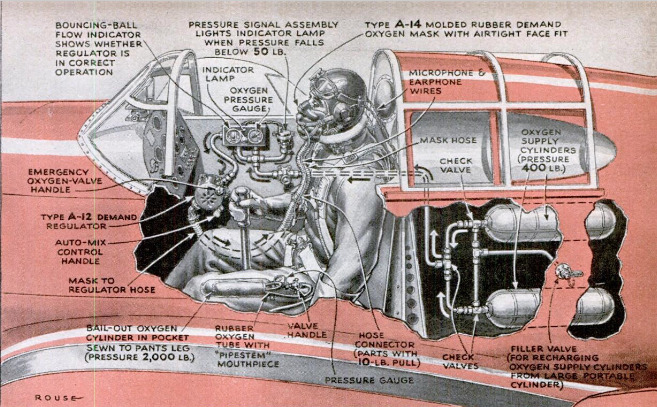

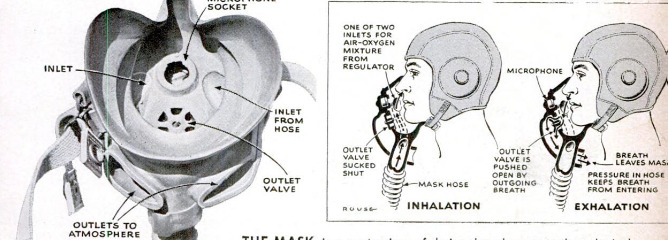

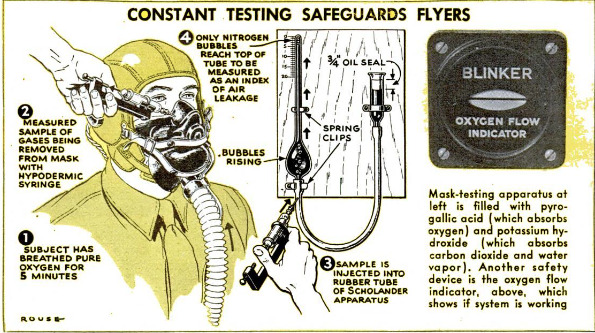

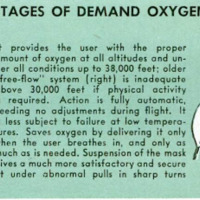

It's called the “demand” system, because

it automatically adjusts its flow to the de-

mand of the flyer's body at any altitude. It

gives him air without extra oxygen at

ground levels. As he ascends into thinner

atmosphere, it automatically begins to add

oxygen to the air he breathes. And, it in-

creases the proportion of oxygen as he goes

up, until at 30,000 feet—when he needs it

most—he's getting pure oxygen.

On night flight, simple adjustments vary

the working of the demand system so that

the flyer gets oxygen, in increasing quanti-

ties, all the way from the ground up. For,

research has shown that lack of oxygen is a

major cause of poor night vision, If oxygen

isn't used, night-vision efficiency drops with

altitude. Effects are noted as low as 5,000

feet.

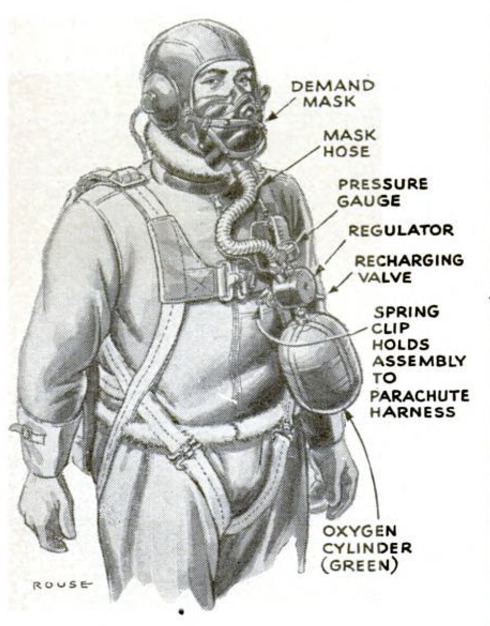

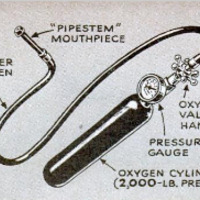

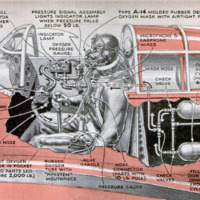

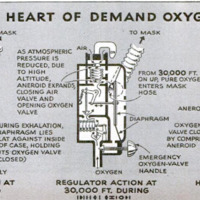

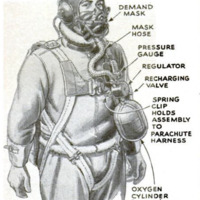

The “thinking” oxygen equipment looks

complex but, in principle, it is relatively

simple. The heart of the apparatus is the

regulator, which gets its oxygen from spe-

cially designed, light but strong cylinders

through a supply line or “trunk line.” Air

comes into the regulator through an air port

which closes automatically at 30,000 feet.

From the ground to 30,000 feet, the propor-

tions of air and oxygen admitted to the

automatic mixing regulator are controlled

by a tiny aneroid bellows control, similar to

that in a barometer, operating two valves.

As the outside air pressure decreases with

altitude, one of these valves opens the oxy-

gen supply inlet farther and farther; the

other closes the air inlet correspondingly.

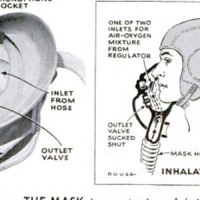

One of the main drawbacks of the old-

style equipment which the new regulator re-

places was its tendency to waste oxygen.

The older types supplied oxygen at all times.

But the automatic regulator now incorpor-

ates a device which cuts off the oxygen flow

every time the flyer exhales and renews it

with each inhalation. This device, a little

diaphragm working a valve, operates on the

differential of pressure induced by the re-

versal of the flyer’s breathing. When he

breathes in, the diaphragm flips to one side |

and a little lever linkage opens the oxygen |

valve. But when he starts to exhale, the |

pressure moves the diaphragm and thus |

shuts off the oxygen-flow valve. |

Sometimes, in flight, the pilot may want a |

momentary “shot” of oxygen. He gets this

through a flip of the finger on the auto-mix |

button of the regulator. This cuts off the

air flow when turned to the “off” position

and thus gives pure oxygen at any altitude. |

If, for some reason, the mechanism should

fail to function, there is another little handle

labeled “Emergency”; this by-passes the en- |

tire regulator mechanism and causes pure |

oxygen to flow directly into the mask feed |

hose.

-

Contributor (Dublin Core)

-

Stewart Rouse (writer and illustrator)

-

U. S. Army Air forces (photos)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-11

-

pages (Bibliographic Ontology)

-

77-80

-

Rights (Dublin Core)

-

Public Domain (Google digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Alberto Bordignon (Supervisor)

Popular Science Monthly, vol. 143, n. 5, 1943

Popular Science Monthly, vol. 143, n. 5, 1943

Schermata 2022-10-18 alle 11.49.55.png

Schermata 2022-10-18 alle 11.49.55.png Schermata 2022-10-18 alle 11.50.01.png

Schermata 2022-10-18 alle 11.50.01.png Schermata 2022-10-18 alle 11.50.06.png

Schermata 2022-10-18 alle 11.50.06.png Schermata 2022-10-18 alle 11.50.12.png

Schermata 2022-10-18 alle 11.50.12.png Schermata 2022-10-18 alle 11.50.19.png

Schermata 2022-10-18 alle 11.50.19.png Schermata 2022-10-18 alle 11.50.32.png

Schermata 2022-10-18 alle 11.50.32.png Schermata 2022-10-18 alle 11.50.37.png

Schermata 2022-10-18 alle 11.50.37.png Schermata 2022-10-18 alle 11.50.43.png

Schermata 2022-10-18 alle 11.50.43.png 1.png

1.png