-

Title (Dublin Core)

-

U. S. bombs and shelters

-

Article Title and/or Image Caption (Dublin Core)

-

U. S. bombs and shelters

-

extracted text (Extract Text)

-

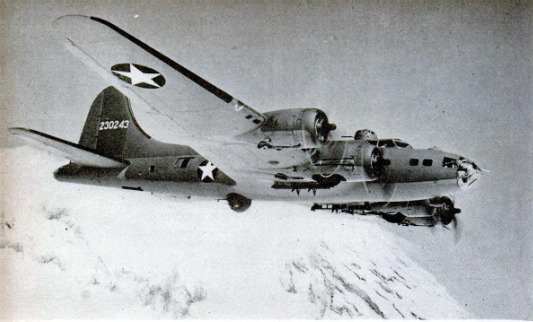

~ HOW 10 TONS OF BOMBS can be carried

by a Flying Fortress is shown strikingly in |

| this view of one of the big Boeing bombers

on a practice flight near Mount Rainier in

; the State of Washington. Outside racks

with forklike fingers hold the extra bombs

on the bottom of the fuselage near the land-

ing wheels. This supplementary arrange-

ment permits the carrying of an unusually

heavy load for limited-range operations.

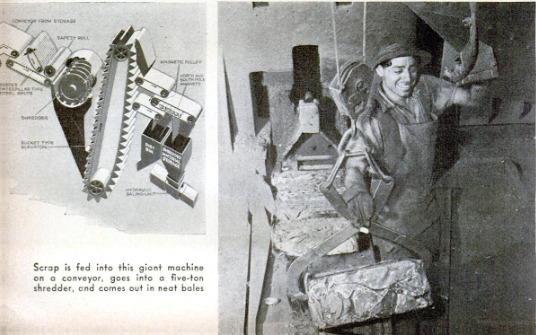

SHREDDED AND NEATLY BALED in 200-

pound packages, tin cans, automobile bodies,

old stoves, and all kinds of scrap iron are

made ready for reprocessing in a huge ma-

chine devised by Clarence M. Gregg, presi-

dent of the Los Angeles By-Products Com-

pany. Chrome molybdenum hammers or

cutters on the outside of a drum revolve at

1,800 r.p.m. to break up the pieces into tiny

bits, which ride through a magnetic sepa-

rator that deposits dirt and nonferrous

metal in one bin and iron in another. Auto-

matic balers then bind the iron scrap into

bales of uniform density. ]

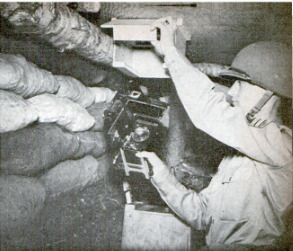

A BOMBPROOF LABORATORY for

processing photographic material at

the front has heen designed by the

165th Signal Photographic Company

at Fort Sam Houston, Tex. As shown

in the drawing by military artist

Swanlund, the underground darkroom pro- |

vides a working space of about six by 12

feet and is entered through a protective

right-angle passageway. One of its features

is a ceiling rack in which a camera can be |

placed, as demonstrated by Sergeant Smoody

in the photograph above, for use in making -

enlargements. Heavy sandbagging guards

against damage by bombs and shells, so

that work can be carried on under fire.

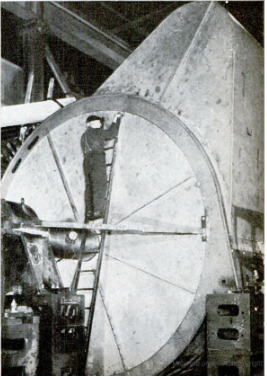

GIANT ENCLOSED MOTORS, such as the

one shown below, are being built by General

Dlectric for tankers of the U.S. Maritime

Commission. Each motor has a sheet-iron

cover as a protection against dirt, and is

equipped with an air-recirculation system.

Cool air entering at the bottom of the motor

rises as it becomes heated and is then piped

off into a cooling blower, which carries it

back to the bottom of the motor.

ALNICO MAGNETS set in

the bases of the standards are

simplifying the setting up of |

experimental optical systems.

Adhering to a metal table top

or wall, the magnets hold the

system in position and pre-

vent any disarrangement even

when adjustments are made.

This use of alnico was devised

by Norman Barnes of Gen-

eral Electric. |

NEW GASOLINE OVENS are

being used by the U.S. Army

Quartermaster Corps for baking

in the field. Shown at right are

eight of these two-chamber

ovens, which can do the baking

for 10,000 men. Tended by a

bakery platoon of 36 men, and

using 3,600 pounds of flour, this

battery of ovens can turn out

5,000 pounds of bread in 24

hours. Below: fire-control units.

A BRAKE TESTER for

airplanes has been de-

veloped by the Safety

Equipment Co., of

South Bend, Ind. The

device cradles the

plane’s rubber tires

between rollers that

provide traction equal

to that of dry con-

crete. When the

brakes are applied,

the force needed to

turn the wheels is

registered on a dial,

which gauges the

braking action.

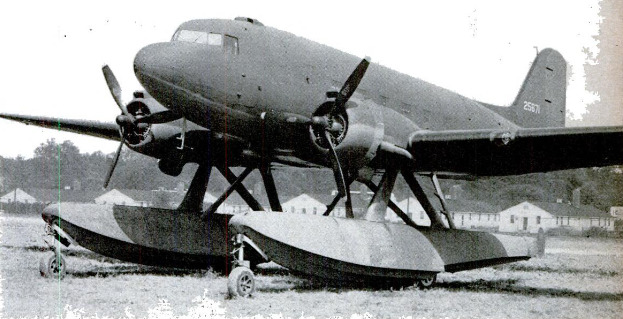

AMPHIBIOUS FLOATS, attached experimentally

to the Army Air Forces’ C-47, may make this big

cargo transport an efficient seaplane as well as a

land plane. Tried out at Wright Field, Dayton,

Ohio, the new floats enabled the plane to alight

on water, taxi to shore, and climb on land under

its own power. This may prove particularly use-

ful in rescues of flyers on coral reefs in the Pacific.

Further experimentation is being carried out by

the AAF in the design and use of the floats.

CLEAR PLASTIC DOMES are being

mounted on open antiaircraft observa-

tion posts along the Atlantic seaboard

to keep sky watchers dry and com-

fortable. Built of Lumarith, made by

the Cellanese Celluloid Corporation, of

New York, the domes offer shelter

from rain, sleet, and snow without

cutting visibility, and also improve

communication by screening out noise.

“GEEHEEBEE" is the name

that U. S. soldiers and sail-

ors have given to the odd

contraption shown at the

left. Much in evidence where

amphibious operations are in

progress, it performs yeo-

man service when repairs or

repainting must be done on

the landing barges and other

small invasion craft.

The “geeheebee” is backed

by a tractor into the surf un-

til it settles over a landing

boat or other small craft,

which is then chained to the

frame. As the tractor pulls

the two ashore, the boat is

lifted clear of the ground.

After repairs have been com-

pleted, the procedure is re-

versed to relaunch the craft.

Empty oil drums on the

“geeheebee” permit it to be

floated ashore from a trans-

port or other large vessel.

PLASTIC EAR STOPPERS are now molded

from Plexiglas to fit the ear canal. De-

signed by Arthur F. Farman, an employee

at McClellan Field in

California, they are

manufactured by Rohm

& Haas Company, of

Philadelphia, Pa.

TWIN THREADS

are a new idea

for screws for

wood, plastic,

and combination

assemblies. These

screws, made by

the Blake &

Johnson Com-

pany, of Water-

ville, Conn., have

straight sides, re-

lieved shank di-

ameter, and a

single balanced

point.

TWO MEN OPERATING

this grid machine, developed

by Lyle F. Pierce, chief of

master layouts at the Boeing

plant in Seattle, can make in

one day a crosshatched back-

ground for full-scale mechan-

ical drawings that once took

six months. The machine

scribes simultaneously 12

parallel lines 100 inches long

and accurate to .005 inch.

Backgrounds thus made

on painted steel are joined

together, sometimes into

sheets 20 by 30 feet, for

basés on which full-size

drawings are put for parts of

Boeing planes.

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-11

-

pages (Bibliographic Ontology)

-

106-111

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

Popular Science Monthly, vol. 143, n. 5, 1943

Popular Science Monthly, vol. 143, n. 5, 1943

Schermata 2022-10-18 alle 15.26.25.png

Schermata 2022-10-18 alle 15.26.25.png Schermata 2022-10-18 alle 15.26.31.png

Schermata 2022-10-18 alle 15.26.31.png Schermata 2022-10-18 alle 15.26.40.png

Schermata 2022-10-18 alle 15.26.40.png Schermata 2022-10-18 alle 15.26.48.png

Schermata 2022-10-18 alle 15.26.48.png Schermata 2022-10-18 alle 15.26.53.png

Schermata 2022-10-18 alle 15.26.53.png Schermata 2022-10-18 alle 15.27.03.png

Schermata 2022-10-18 alle 15.27.03.png Schermata 2022-10-18 alle 15.27.10.png

Schermata 2022-10-18 alle 15.27.10.png Schermata 2022-10-18 alle 15.27.22.png

Schermata 2022-10-18 alle 15.27.22.png