-

Titolo

-

Aircraft Propellers Explained

-

Article Title and/or Image Caption

-

What You Should Know About Propellers for Our Fighting Planes

-

extracted text

-

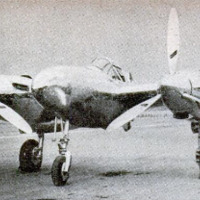

AFTER a recent battle, American forces

captured a German soldier who kept

pointing upward and babbling about “big

whirling swords.” Some time later, doctors

discovered the cause of his hallucinations.

Lightning and Warhawk fighters had run

interference for the Yank advance by carry-

ing out one of their blistering strafing at-

tacks at tree-top altitude. The Nazi had

somehow escaped from his flaming tank and

survived the assault; but, in his fear, he had

psychologically identified the sunlit, spinning

propeller blades of the low-sweeping planes

as whirling swords.

Indeed, in a more practical manner, the

whirling prop blades of our warplanes do

symbolize their deadliness. The propellers

that pull our fighters and bombers—and

those of our allies—through the skies over

half a dozen war theaters are more than a

little responsible for the superb performance

that is affording American-made craft the

air superiority they now enjoy. The prop

is as much a part of the plane's power plant

as is the engine. It translates the engine's

power output into the “thrust” necessary for

sustained flight.

If we consider the propeller as a screw

working its way through the air and pulling

the plane along—or pushing it along, if it is

mounted aft of the engine, as in the case of

our Bell Airacuda and

some of the new push-

er-type fighters—just

as a steel screw bores

its way through a

piece of wood, the

principle of propulsion

is reduced to its sim-

plest terms. But, un-

like the screw, which

advances by pushing

the rear face of its

thread against the fi-

bers of the wood, the

prop advances by

creating just ahead of

its whirling blades an

area of suction into which they are drawn.

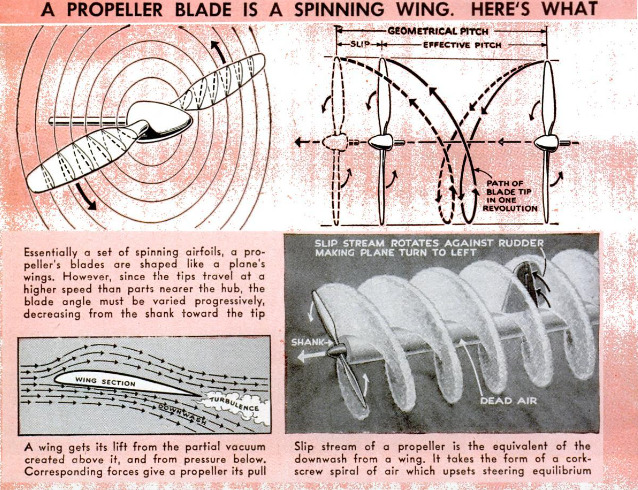

The propeller blades are shaped exactly like

the wing section of a plane and act on the

same principle. The prop is, to all intents

and purposes, a set of spinning airfoils.

Just as the airplane wing must move for-

ward fast to maintain its lifting properties,

the propeller must rotate swiftly in order

to provide thrust. The faster it turns, the

more thrust results—up to a certain point.

And, just as the wing is tilted upward slight-

ly in order to deflect the air downward (this

setting is called “angle of attack”), the

prop’s blades are twisted 50 as to deflect the

air rearward. This twist, or “blade angle,”

enables the blades to meet the air at an an-

gle that is most favorable for thrusting ef-

ficiency.

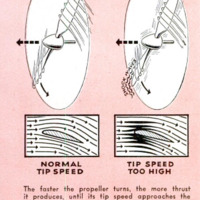

In rotating, the tips of the propeller must

travel around their greater radius within

the same time that the prop hub completes

a revolution. The tips, therefore, travel

may times faster than the center of the

prop. For this reason, the blades are not

straight like a wing but twisted so as to

permit the blades to meet the air at the

optimum angle along the entire length of

the propeller. The twist is most noticeable

in the inner half of the blade. Within a foot

or 50 of the hub, the blade merges from its

flat shape into a round, thick section that

provides no thrust whatsoever.

The very same laws of physics which per-

mit a wing to lift or a propeller to thrust

have decreed that we must pay a price for

these aeronautical services. The steepest

of these prices is drag. It is with drag that

the propeller must struggle constantly as it

pulls or pushes the plane through the air.

Drag acts on the prop in the same way as

on the wing, only more so because of the

high speeds at which the prop rotates. Drag

may be diminished by giving the wing sec-

tion or prop blade a more streamlined shape.

The new laminar-flow wing section—usedon the superb North American Mustang

fighter-bomber and other American craft—

has reduced drag almost 67 percent, and this

same type of airfoil section is used by some

of our propeller manufacturers.

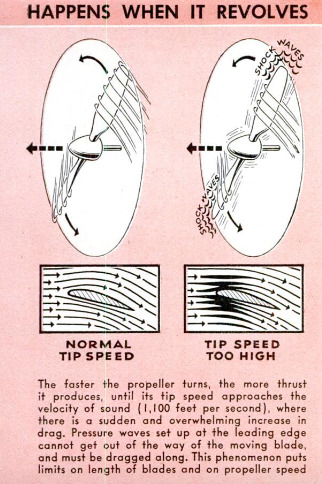

Greater efficiency may also be achieved

by increasing the area of the blade to pro-

vide more thrust, but it is here that the en-

gineers encounter trouble. The diameter of

the propellers is limited by three considera-

tions: on single-engined craft, the prop

must be short enough to allow clearance

when the ship is on the ground on level keel.

On multiengined planes, ground clearance

is not such an important factor because

these ships are larger and sit higher, but

using bigger props means moving the en-

gines farther apart (and the outboard en-

gines farther out on the wing). When these

difficulties are overcome, there remains still

another: the larger the propeller’s diameter,

the higher the tip speed. When the tips of

the prop reach the speed of sound—1,100 feet

per second—they become literally barnacled

with a peculiar and exaggerated drag con-

dition called a “shock wave.” There are

limitations on the width of the blades, too.

As the blade is widened, it must be made

heavier for structural reasons, and this re-

sults in greater drag and weight. Compro-

mise is necessary for other reasons which

have to do with more involved aerodynamic

laws, and the product is the neatly tapered,

knifelike propeller blade we see on today’s

warplanes and airliners.

Notwithstanding these difficulties, the pro-

peller is just about the most efficient part of

the airplane. How it got that way is some-

what of a story. Some of the earlier props

were nothing more than twisted

airfoils, the blades being built

up of wooden ribs and covered

with cloth. Then they were

hewn out of a solid piece of tim-

ber. The first really serviceable

propellers were made of lami-

nated wood; these proved relia-

ble and aerodynamically efficient

throughout the crucial years of

aviation, and some of this type

are still used for small civil

planes and military trainers.

Early experiments with steel

propellers were conducted in

1917, prompted by maintenance

difficulties in World War I. Dur-

ing the next two years, several

hollow steel props were tested by the Army

Air Corps, and one solid steel model per-

formed satisfactorily. In 1921, earnest de-

velopment of the aluminum-alloy blade was

undertaken, and the ease of making blades

from solid stock, as compared with the ex-

pense of fabricating hollow steel blades by

the then available methods, made aluminum

more desirable. These dural blades and

hubs gained wide popularity, and the steel-

prop development lagged.

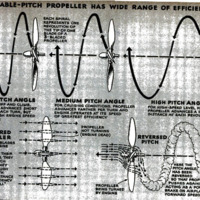

The improvement in performance and

durability brought metal propellers into al-

most universal use during the late 20's; the

most famous of these were the Hamilton

Standard and Curtiss Reed, both made of

dural. These props, of course, had a fixed

blade angle, or pitch. As long as aircraft en-

gines remained in the 500-horsepower brack-

et and 160 miles per hour was considered a

lot of speed, the fixed-pitch propeller was

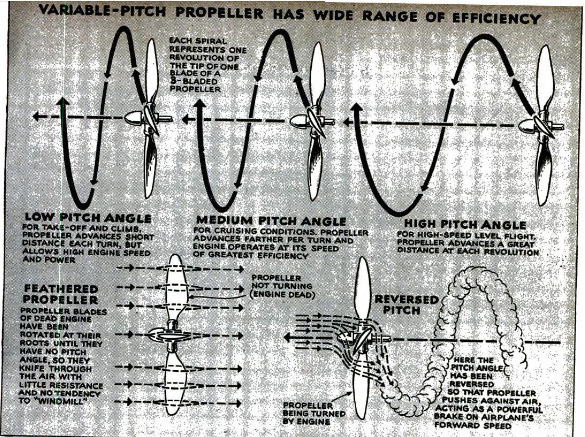

adequate. As engines became more power-

ful and the demands for performance in-

creased, power-plant limitations were re-

lieved by the introduction of the adjustable-

pitch prop, whose blades could be set to low

or high pitch—or a happy medium—and

clamped securely in the hub. In low pitch,

the plane had fine take-off and climbing

characteristics but was short on speed: in

high pitch, with the blades turned to meet

the air at a greater angle, the plane de-

veloped maximum speed but its take-off

and climbing ability was not what it might

have been. A compromise setting, however,

gave the craft good all-around performance.

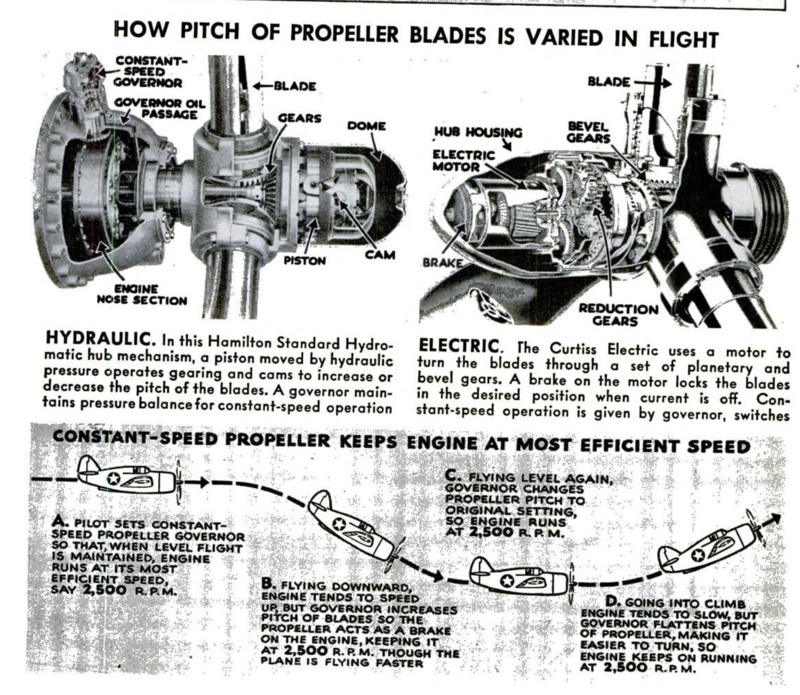

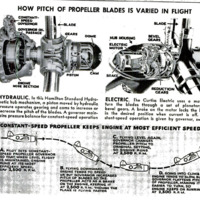

As the pioneers had pointed out many

years before, what the flyer really needed

was a propeller whose pitch settings could

be changed during flight. In 1933, the Col-

lier Trophy was awarded to Hamilton Stand-

ard for the development of a successful

controllable-pitch propeller whose blades

could be set at high or low hydraulically

through a control in the cockpit that actu-

ated the hub mechanism. During the same

year, Curtiss perfected an electrically con-

trolled propeller. By taking off with the

prop blades in low pitch, fiyers got their

‘ships off the ground in 35 percent of the dis-

tance formerly required and increased their

rate of climb approximately 30 percent.

When they reached the desired altitude, the

shift was made to high pitch, with the re-

sult that top speed was increased almost 15

percent. For higher flights, an additional

20-percent increase in the plane's service

ceiling was obtained. The ingenuity of

Hamilton Standard and Curtiss-Wright en-

gineers greatly influenced airplane and en-

gine design by making possible the use of

larger and faster military craft and trans-

ports. The Lycoming-Smith electric con-

trollable-speed prop became popular for

lower-powered civil airplanes.

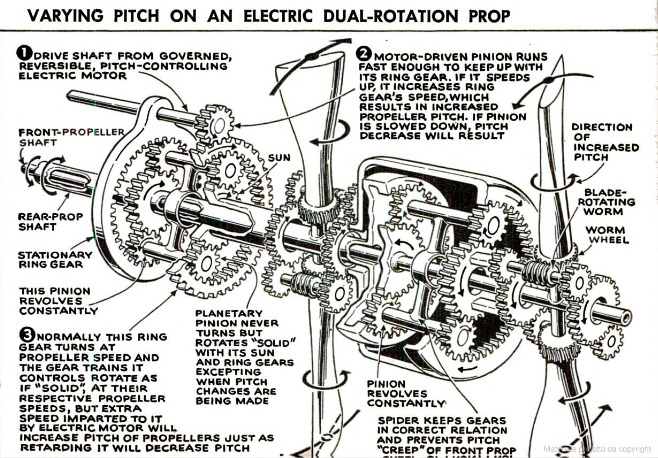

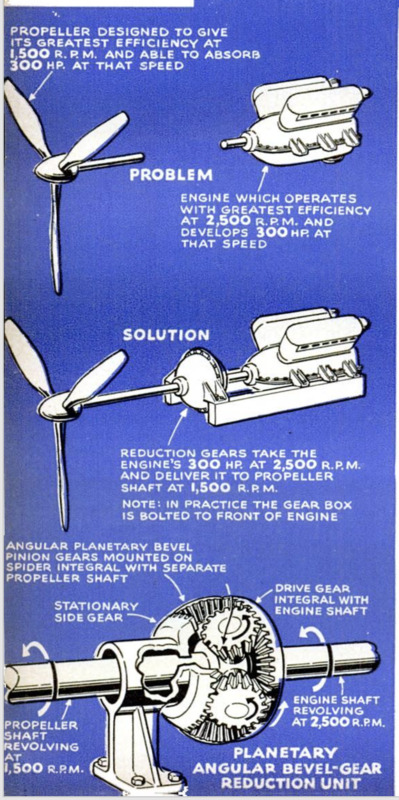

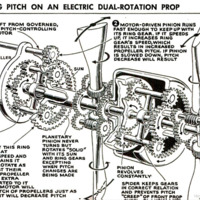

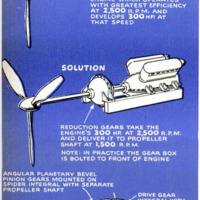

But with the advent of 1,000-horsepower

engines, this business of changing blade

pitch required further refinement. The en-

gine and prop have to be carefully mated;

for maximum performance, each has to

make concessions to the other,

and for every combination of

engine and propeller there is

an optimum speed for the two.

The engine's top power output

is gained at a constant r.p.m., or

crankshaft speed. This is gen-

erally higher than the propel-

ler's optimum speed, and reduc-

tion gears are set into the en-

gine nose section to slow down

the prop to three quarters or

half the engine speed.

In #s job of trandiatine the

engine's horsepower into useful thrust, the

prop also acts as a brake on the engine.

But this braking effect must be carefully

controlled or the engine will not function

at its best. The two-position propeller is

not sufficiently flexible in its operation to

absorb the output of today’s high-powered,

highly super-

charged engines, If the propeller were,

however, able to vary its blade pitch grad-

ually from zero-angle low pitch up to 90

degrees high pitch, it would be flexible

enough to absorb the engine's full horse-

power at all altitudes. The constant-speed

propeller is such a type. The prop and en-

gine act as checks and balances against

each other under all conditions of flight.

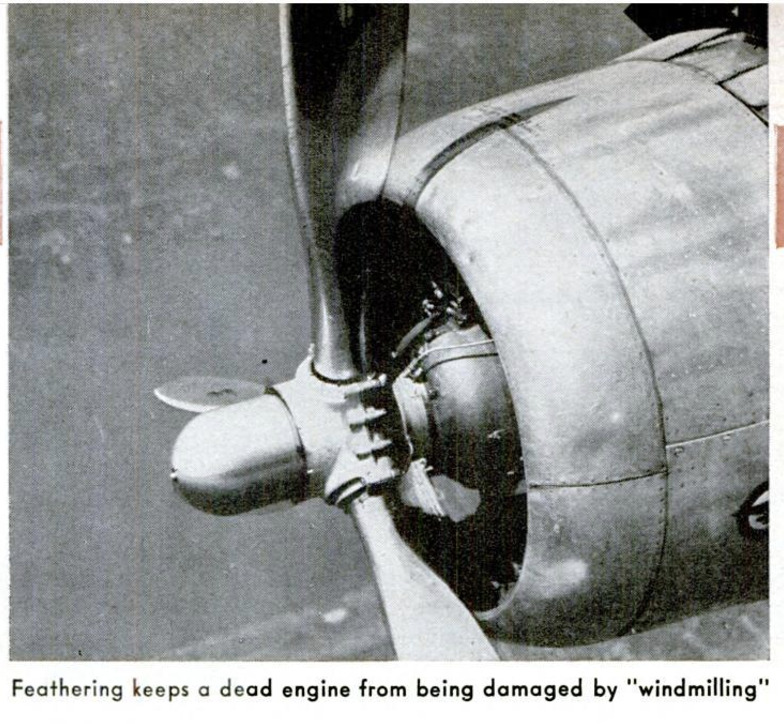

For emergency operation in the case of

multimotored airplanes, this business of

changing blade pitch has been carried a

step farther to permit the “feathering” of

the prop. The blades are turned in their

hub through highest pitch until they are

edge-on into the wind. The propeller is, of

course, useless for thrusting in this posi-

tion, but feathering is an expedient for fly-

ing with one or more engines out of opera-

tion, either by design or accident. Four-

engined transports frequently cruise on only

two of their engines, but this would not be

considered good flying practice if full-feath-

ering propellers were not available. Should

an engine go dead in an emergency, the

prop is feathered into the wind immediately;

the prop in this position acts as a brake on

the dead engine. In normal operating pitch,

the prop would be subjected to “pinwheel

ing,” just as the toy pinwheel spins when

held to the wind, and this might result in

a damaged engine. All the feathered pro-

peller does is create a drag. A windmilling

prop, however, would create more than 20

times this drag. The feathered propeller

adds about 1,500 feet to the service ceiling

of a twin-engined Douglas C-47 cargo trans-

port fiying on one engine and makes the

plane much easier to handle. Even a single-

engined airplane is at an advantage when

fitted with a feathering prop because, in

emergency, the plane's gliding range is half

again as great with this type as it would

be with a windmilling, unfeathered prop.

Carrying the pitch angle beyond the 90-

degree feathered position into reverse pitch

was a logical step in propeller development

made first by Curtiss-Wright. The reversi-

ble-pitch prop, Which delivers negative

thrust, is extremely useful as an air brake.

In some instances, it may be used to slow

the landing run of planes, but its most prac-

tical application is found ou multiengined

flying boats. Maneuvering a flying boat w

the water is, at best, a tricky operation.

The reversible prop facilitates maneuvering

in general and turning m particular. By

reversing the two inboard propellers and

leaving the outboard props in normal pitch,

the pilot of a four-engined flying boat can

“come about” in one-fourth the turning ra-

dius of a similar craft with conventional

propellers.

Under the most favorable conditions, the

prop is capable of translating 86 percent

of the engine's horsepower into useful thrust,

and props have a specific weight of between

22 and .38 pounds per horsepower. (There

are only three or four aircraft engines in

the world that are known to have a weight-

horsepower ratio of less than one pound per

horsepower.) It is because there is so lit-

tle room for improvement that propeller en-

gineers are burning up much midnight ofl

and energy in their quest for increased pow-

er-plant berformance.

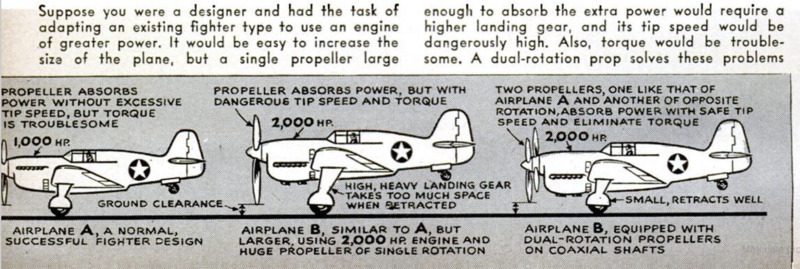

It has been mentioned that the adapta- |

tion of the laminar-flow airfoil section

which holds the stream of passing air close

to the surface and cuts down turbulence

and drag to prop blades increased their |

efficiency, and that engineers have sought to

increase the blade area to gain more thrust

and absorb the output of higher-horsepower

engines, The compressibility phenomenon

of the shock wave makes the engineers host.

fate to. Mereate blade diameter. Bigger

‘props could be used only if they were geared

Gown to turn slowly enough that the tips

would not reach the speed of sound. When

an airfoil attempts to exceed this speed, the

pressure wave created at its leading edge

Cannot move ahead of the airfoil, The com.

pressibility cannot get out of the way of

the wing or propeller and must be carried

along with i, Just as the bow wave of a

Steamer Is cast upward instead of outward

‘along. the surface when high speed is at-

tained. Unlike the much denser water, the

air has nowhere to go and must be dragged

along, coating the. propeller with tightly

Packed, turbulent air that does nothing but

Create buch drag that the airfoil loses much

Gf ita thrusting ability.

Hamilton Standard engineers increased

their blade aren without extending the diam-

eter by making the blade paddle-shaped

from the shank outward. The paddle blade

a wider, with & more founded tip, and is |

stil structurally strong enough at the shank

to withstand the many stresses. There is,

However, a limit to the width of the biade.

The ability to absorb the engine's power fn.

creases directly in proportion to the width

of the blade, but, unfortunately, the weight

Micreayes with the sgtare of the Width, |

When the blade is made thicker, it dis-

places more air and builds up compressibility

more readily.

There are still other more involved limi-

tations. One of these was the problem of

cooling the radial-type engines, since the

slip stream, or backwash of air from the

prop, is hollow in the middle because of the

blades’ shape. This was overcome by fit-

ting the blades with cuffs that continue the

airfoil shape right down to the hub. This

additional surface provides larger thrust

area and also brings the hole in the center

of the slip stream down almost to nothing.

Part of the backwash is then able to enter

the engine cowl and contribute to cooling.

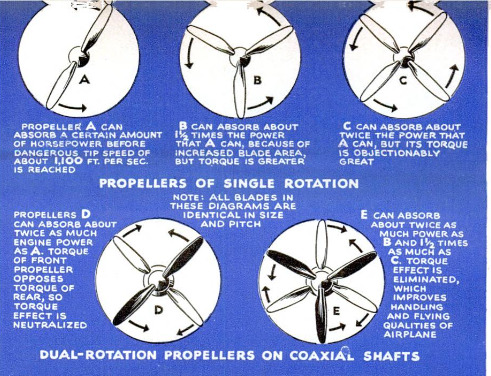

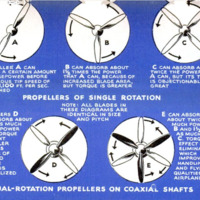

The next obvious step in gaining thrust-

ing area was the use of more blades. When

planes began to use the bigger engines, the

demand for more than three blades forced

engineers to solve the vibration problems in-

troduced by four- and six-bladed props.

Four-bladed propellers of wood were used

in World War I, and were reintroduced by

Curtiss in hollow steel form in 1939. Planes

that use four-bladed props include the Mar-

tin Marauder, Republic Thunderbolt, North

American Mustang, and Britains Spitfire

IX (with a British Rotol prop).

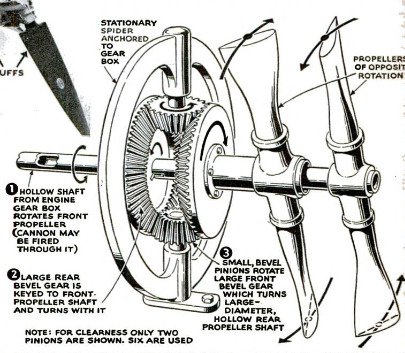

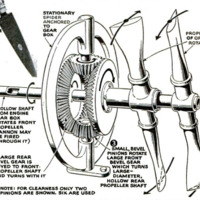

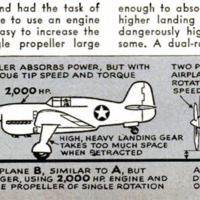

The ultimate in props today is the four-

or six-bladed dual-rotation job, which con-

sists of two units mounted on coaxial shafts

which turn in opposite directions. Even these

have been fitted with constant-speed, feath-

ering hub mechanisms by Curtiss, Hamilton

Standard, and General Motors, and by Ro-

tol and De Havilland in Britain. They are,

literally, two propellers and naturally are

heavier than a single prop. But because they

can be of smaller diameter and blade width,

the weight is not actually doubled but is

only about one third greater. The dual-ro-

tation props are worth their weight in per-

formance. First of all, they do away with

the evils of torque, or swinging action in

flight, since the torque of one set of blades

cancels out that of the other unit. Shorter

landing gears can be used because of the

smaller blades, and this results in a great

saving of weight and improved landing be-

havior of the plane. At speeds around 400

miles per hour, the contra prop increases

aerodynamic efficiency more than five per-

cent. The rear prop picks up the whirling

slip stream of the forward set of blades

and converts it into useful thrust.

The engineers are hard at work on still

newer ideas, but the dual-rotation prop

will be with us for many years to come.

-

Autore secondario

-

James L. H. Peck (writer)

-

Stewart Rouse (illustrator)

-

Lingua

-

eng

-

Data di rilascio

-

1943-11

-

pagine

-

122-127, 212, 216, 218

-

Diritti

-

Public Domain (Google digitized)

-

Archived by

-

Matteo Ridolfi

-

Alberto Bordignon (Supervisor)

Schermata 2022-10-18 alle 15.47.50.png

Schermata 2022-10-18 alle 15.47.50.png Schermata 2022-10-18 alle 15.47.57.png

Schermata 2022-10-18 alle 15.47.57.png Schermata 2022-10-18 alle 15.48.02.png

Schermata 2022-10-18 alle 15.48.02.png Schermata 2022-10-18 alle 15.48.09.png

Schermata 2022-10-18 alle 15.48.09.png Schermata 2022-10-18 alle 15.48.15.png

Schermata 2022-10-18 alle 15.48.15.png Schermata 2022-10-18 alle 15.48.22.png

Schermata 2022-10-18 alle 15.48.22.png Schermata 2022-10-18 alle 15.48.28.png

Schermata 2022-10-18 alle 15.48.28.png 1.png

1.png 2.png

2.png 3.png

3.png 4.png

4.png