-

Title (Dublin Core)

-

The Evolution of Naval Guns and Armor

-

Article Title and/or Image Caption (Dublin Core)

-

The Evolution of Naval Guns and Armor

-

extracted text (Extract Text)

-

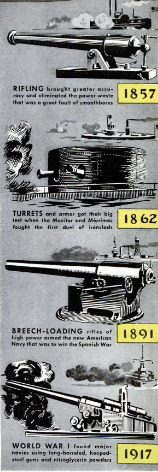

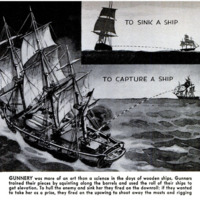

RIVALRY between makers of warship

armor and of guns and projectiles to

smash it—a never-ending contest—reaches

a higher pitch today than ever before.

Thundering turrets of hostile men-of-war

are proving that no weapon has yet out-

moded naval artillery. Both in engage-

ments of limited scope, and in the Allies’

grand clash with Japan's main fleet that

some observers predict will once and for all

settle the control of the seven seas, the

clang of metal against metal may well be

the final arbiter.

Will a shell penetrate the vitals of an

enemy ship, where it will cause enormous

havoc when it explodes? Will it get stuck

halfway through the armor and do only

minor damage ? Or will it harmlessly glance

Off the ship's protective belts of steel? Ques-

tions like these preoccupy the U. S. Navy's

Bureau of Ordnance, just as similar prob-

lems confronted designers of the first can-

non used aboard ships in the year 1400 or

thereabouts. Highlights of developments

from that time to the present offer an il-

luminating glimpse of the evolution of naval

gunplay.

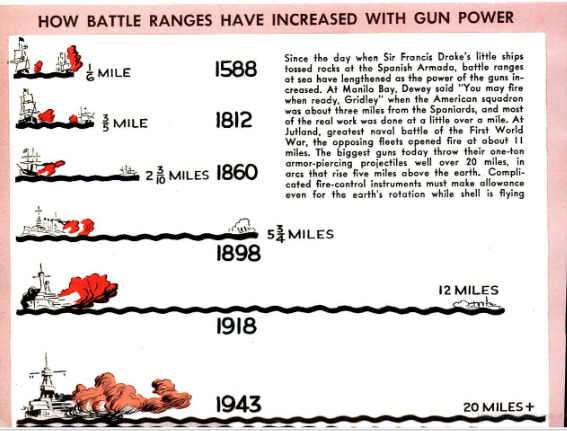

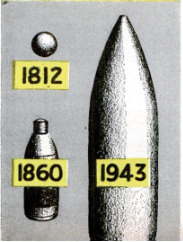

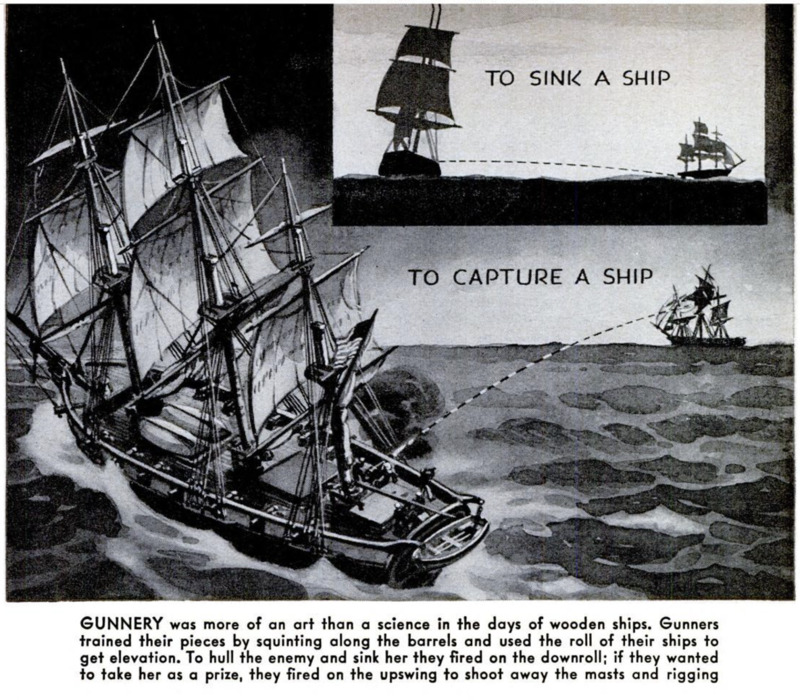

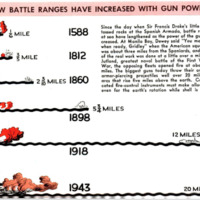

What we now call fire power first became

recognized as the decisive factor in war at

sea when the superior shooting of Sir Fran-

cis Drake’s English fleet defeated the Span-

ish Armada in 1588. Drake’s cannon were

crude weapons of brass or iron, cast hollow

on a core, but they packed the punch

that brought him victory.

About 1750, a Swiss mechanic in-

vented a boring machine, which made

it possible to cast a cannon solid and

then bore out its barrel with reasonable

precision. Guns made in this way were

more powerful and accurate than the

hollow-cast kind.

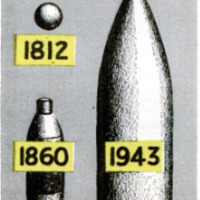

Dy the year 1sUo, when Lhe Driush

defeated the French and Spanish in the

celebrated naval battle of Trafalgar,

Nelson's victorious ships of the -line

mounted the best guns of their time.

These 32-pounders—so called from the

weight of the iron cannon balls they

fired—measured nearly 10 feet long

and weighed three tons. Their point-

blank range was 350 yards, the distance

at which decisive sea engagements then

were fought; and their extreme range,

a mile and a half. Probably their pene-

trating power compared with that of

the foot-longer 24-pounders carried by

the U. S. frigate Constitution in the

War of 1812—22 inches of oak at 1,000

yards. Including smaller weapons, Nel-

son's biggest ships were armed with

considerably more than 100 guns apiece.

But when about half of them fired a

broadside, they sent no more than 1,300

pounds of iron hurtling at the enemy—

less than two thirds the weight of a

single armor-piercing projectile from a

modern 16-inch gun.

A momentous advance in naval gun-

nery—the introduction of explosive

shells—came in 1822. Paixhans, a

French artillerist, designed an eight-

inch flat-trajectory cannon whose 62-

pound shell contained a bursting charge

of four pounds of black powder. Tests

proved that this projectile had a tre-

mendous incendiary effect upon a wood-

en ship. But conservatism in the French

Navy was so strong that the new weap-

on was not adopted until 1837. The

British hesitated two years more before

producing a similar shell gun, to be

used along with their time-tested 32-

pounders

For 15 years after the French and

British began arming their ships with

shell guns, neither did anything useful

about protecting their ships from these

weapons. After a few sketchy trials in

which guns shot holes through thin

cast-iron plate, it was decided offhand

that armor was no good.

Gunmakers made the most of their

temporary advantage. Muzzle-loading,

smoothbore cannon reached the peak

of their development in America, with

production, by 1856, of Dahlgren guns

for our Navy, ranging in bore from

nine to 11 inches and capable of firing

either shells or solid shot.

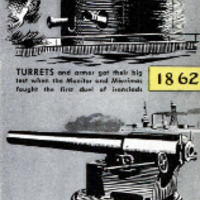

Advocates of armor now saw the

doom of warships lacking it. The

world’s first seagoing ironclad, La

Gloire, completed by the French in

1859, sheathed her wooden hull with

armor plate 41; inches thick. Britain

countered in 1861 with the Warrior,

an all-iron warship with the same

armor thickness. Across the Atlantic,

spurred by the Civil War, Federal and

Confederate forces were racing to

complete the first American ironclads

—the celebrated Monitor and Merri-

mac. It was almost a photo finish.

Hardly had the Confederate rebuilt

frigate begun sending wooden Federal

ships to the bottom before, on the

morning of March 9, 1862, the Fed-

eral warship Monitor arrived at

Hampton Roads, Va., and went into

action, It was the first time in history

that ironclad tangled with ironclad.

Neither ship won a decisive victory.

The Monitor's two 11-inch Dahlgren

guns—the same size as those on Ger-

many's “pocket battleships”—were

mounted on a revolving turret that

went out of order during the battle.

Nevertheless, the “cheesebox on a

raft” was able to outmaneuver the

unwieldy Merrimac and to present a

small target for her 10 guns, of which

the largest were nine-inch Dahlgrens.

The net result was that the Merri-

mac’s four-inch bars of armor and the

Monitor's five-inch side armor and

eight-inch turret armor were only

dented. At least, the legend of the

all-conquering Merrimac had been

buried at sea.

~The next move was up to the gun-

makers. Their answer was to substi-

tute rifled guns for those of smooth

bore. True, some of the Merrimac’s

smaller guns had been rifled, like

those of the British Warrior; but none

had received extensive trials.

Rifling consists of a helical-shaped

insert within a gun barrel, which

spins the projectile as it leaves the

gun. This steadies a shell in flight, so

that it keeps accurately headed for its

target instead of tumbling over and

over. But there was another advan-

tage of rifling that attracted early

designers.

Smoothbore guns wasted power.

Round shot had to fit so loosely, to

avert danger of explosion if it stuck

in the bore, that a quarter of the pro-

pelling gasses escaped around it. Ri-

fling permitted the use of

an elongated, tight-fitting

projectile.

However, many cast-iron

rifled guns burst, because the

charge required to start the

projectile on its way had to

be heavier to overcome the

10-percent retarding effect of

the rifling. The obvious reme-

dy was to build guns of steel,

with four times the tensile

strength of cast iron. Krupp,

German armament maker,

tried it as early as 1851. But

steel was expensive and hard

to get until, in 1857, Besse-

mer perfected his process of

making it cheaply and in

quantity. After that, rifled

guns improved rapidly.

Now guns and arms once

more were on even terms. In

1875. the British commis-

sioned the Devastation, considered the

world’s first modern warship. She was the

first large seagoing fighter to dispense with

sails. Her 25-ton muzzle-loading rifles were

mounted in turrets protected by 14 inches of

armor, and she had a 12-inch armor belt

along her water line. A little later the

French built a ship with 15 inches of armor.

Then, in 1881, the British launched the

thickest-armored ship ever built—the In-

wvincible, with a 24-inch-thick armor belt and

17 inches of armor over her turrets. Her

main battery numbered 16 81-ton muzzle-

loading rifles—the last muzzle-loaders that

were mounted on a first-class battleship.

The earlier smoothbore guns were pot-

bellied because it took a lot of cast iron to

withstand the chamber pressure set up by a

propelling charge of fast-burning black

powder. They were short-barreled, since

there wasn’t any use of having a long barrel

in which the pressure dropped 90 percent

after the cannon ball had traveled one foot;

on the rest of the way to the muzzle, it was

moving much faster than the gases which

should have been propelling it. About 1880,

slower-burning brown powder became avail-

able. Its large, perforated grains exploded

progressively and built up increasing gas

pressure behind the projectile. Use of this

powder reduced chamber pressures and

made long barrels pay dividends in aug-

mented muzzle velocity. Naval guns lost

their potbellies and began to assume their

present lean form.

Three years after the Invincible had been

launched, the British themselves canceled

her invincibility with next to the largest

naval gun ever built—a 16%-inch monster

which, at a range of 1,000 yards, could send

a 1,2800-pound projectile through 34 inches

of wrought iron. Those were dark days for

the armorers, whose problem seemed hope-

less—until nickel-steel plate, the first great

improvement in armor plate, was intro-

duced in Europe in 1889. In the same year

our Carnegie and Bethlehem plants were

producing it. The next year, they turned

out even more efficient armor, face-hard-

ened by the Harvey process.

The day of the heavily armored, big-gun

ship had dawned. After letting our fleet

rust from the Civil War to the mid-1880's,

Congress appropriated funds for the ships

that became world-famous as the White

Squadron. We bought guns from England,

brown powder and armor plate from Ger-

many, and armor-piercing shell from

France. Then the lawmakers wisely decreed

that only materials of American make

should be used in building our new Navy—

a move which led to the establishment of an

armament industry in the United States.

Once more the armor-makers suffered a

setback. Smokeless powder, a slower-burn-

ing and more powerful propellant than

brown powder, appeared in Europe and soon

was in production here. By about 1890,

American steel companies began forging

armor-piercing shells, and we soon were

making the high explosives that supplanted

powder as the bursting charge in them. Our

gunmakers produced 13-inch turret guns

for the battleship Oregon.

Our new guns and ships were tested at

Manila Bay and Santiago, and the United

States came out of the Spanish War a world

naval power. Ever since then, our guns and

armor have been at least as good as those of

any other nation.

In 1316 we mounted 16-inch guns on 11e

Maryland, and the Japanese brought out

their Mutsu class with 16-inch guns. The.

biggest British battleship guns used in

World War I were of 15-inch size. Two 18-

inch guns, the largest ever to go to sea,

were mounted by the British upon the

cruiser Furious. Soon, however, the ship

was converted into a carrier, and the guns.

went to Singapore as harbor-defense Weap-

ons. Presumably, the Japs have them now.

So far as is known, the biggest guns of

French, German, and Italian warships are

15-inch. Britain used 16-inch guns for the

first time in her Rodney class of 1925; went

back to 14-inch for the King George V class

in 1939; and returned to 16-inch for her new

Lion class.

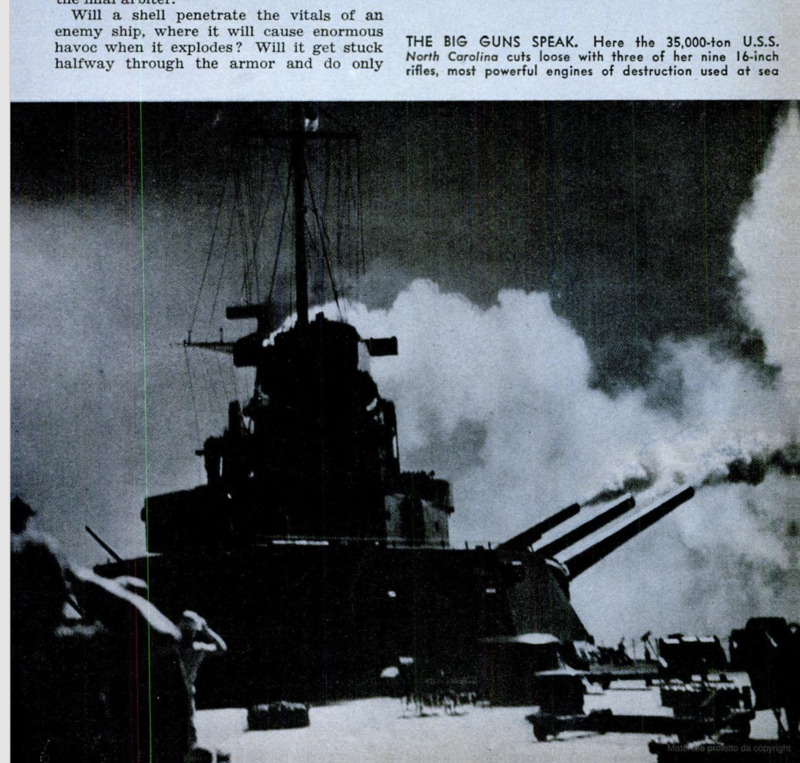

All new American battleships, including

the 35,000-ton North Carolina class and the

45,000-ton Iowa class, employ main bat-

teries of 16-inch guns. Modern design makes

them the most powerful engines of destruc-

tion that have ever been used at sea. They

weigh 100 tons. Their one-ton armor-pierc-

ing projectiles travel a half mile a second.

Fired at an elevation of 42 degrees, they

have a range of well over 20 miles, and

crash down upon armored decks from a

five-mile-high arc.

Bigger guns would have more destructive

power, but would impose increased difficul-

ties in ammunition handling, and a slower

rate of fire. Unless we see sensational im-

provements in armor, 16-inch guns will

probably be the largest that will ever be

used aboard a battleship.

Guns of six smaller sizes now are being

built for our Navy—eight-inch for heavy

cruisers; six-inch for light cruisers; five-

inch dual-purpose guns for the all-five-inch-

gun cruisers of the Juneau class, for sec-

ondary and antiaircraft batteries of the

larger ships, and for our new destroyers;

three-inch for DE boats, merchant ships,

and various other craft; and 40-mm. Bofors.

type and 20-mm. Oerlikon-type automatic

antiaircraft guns for numerous classes of

ships. Fourteen-inch guns still are used—

and are highly effective—on many battle-

ships, and four-inch guns (some of them

adapted for antiaircratt fire) are on World

War I destroyers now in service, but guns

of these calibers are not being built now.

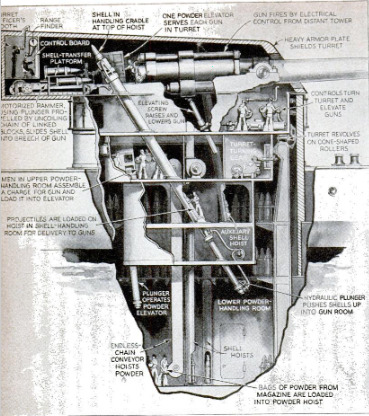

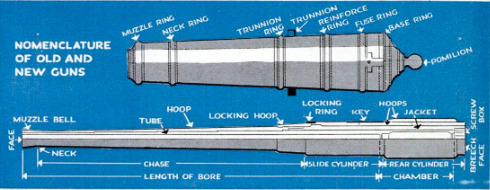

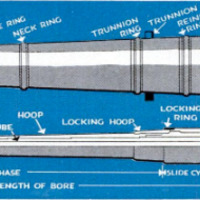

Our naval guns are of two kinds—built-

up and radial-expanded.

S18 FOeilice 4 wici WOC JavESH SUn8

used in the turrets of our battleships all are

of the built-up type. Most of them are built

of five layers of metal—liner, tube, jacket,

and hoops. Initial bore compression is ob-

tained by shrinkage; then the jacket and

hoops are heated and shrunk into place over

the tube. Bag ammunition is used in these

guns. First the projectile is loaded; then the

propelling charge, contained in one or more

silk bags, each with an ignition charge in

its base, is loaded behind it. The breech

mechanism is a rotating block with an in-

terrupted-screw plug which may be entered

or withdrawn in one motion and locked or

unlocked by a part turn. A safety device

prevents the firing of the gun until the

breech is closed. Combination primers are

used, but normally firing is by electricity.

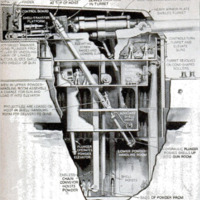

In ships built since 1916, guns from eight-

inch to 16-inch caliber have been mounted

in three-gun turrets. A turret of a battle-

ship of the Jowa class weighs as much as a

destroyer. The turret is built in three parts

—foundation, barbette, and turret proper.

The turret foundation is a cylindrical struc-

ture of heavy girders and beams built into

the structure of the ship; it supports a cir-

cular track carrying rollers on which the

turret rotates. The barbette is a stationary

cylinder of heavy armor, which surrounds

the turret foundation from the ship's lowest

protective deck up to the armor skirt se-

cured to the turret. The turret proper is a

heavily armored, boxlike structure which

rotates, and in which the guns are mounted;

in it also are the power rammers with

which the guns are loaded.

Guns of eight-inch and smaller caliber are

built by the radial expansion process. Our

eight-inch and six-inch guns are composed

of a tube and a shrunk-on jacket which ex-

tends halfway from the breech to the muz-

zle. The eight-inch and many of the six-

inch guns are mounted in three-gun turrets,

have breech and firing mechanisms of the

same types as the larger turret guns, and

use bag ammunition.

Since 1898 all navies have used Krupp-

process armor, face-hardened to break up

projectiles, for water-line belts, barbettes,

and turret sides. It has been greatly im-

proved by American makers in recent years.

For horizontal protection our Navy uses

homogeneous plate, which tends to “dish”

without cracking when it is exposed to

oblique hits. Most modern battleships have

a protective deck six inches or

more thick over their vital parts,

and their turret tops are as

heavy. Our battleships general-

ly have been more heavily ar-

mored than any other navy's

ships of like size. The new ones

are protected by vertical armor

belts over one foot thick—how

much, Japan would like to know.

-

Contributor (Dublin Core)

-

Arthur Grahame (writer)

Frank Hubbard (drawings)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-12

-

pages (Bibliographic Ontology)

-

51-57

-

Rights (Dublin Core)

-

Public Domain (Google digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Alberto Bordignon (Supervisor)

Popular Science Monthly, vol. 143, n. 6, 1943

Popular Science Monthly, vol. 143, n. 6, 1943