-

Title (Dublin Core)

-

U.S. infantry fights in aluminum armor

-

Article Title and/or Image Caption (Dublin Core)

-

U.S. infantry fights in aluminum armor

-

extracted text (Extract Text)

-

BODY armor is reducing the number of

casualties among the American infantry-

men storming into the heart of the Jap

homeland.

Like the knight of the Middle Ages, the

GI is protected against the lance of battle

—in modern war, the shell fragment. The

armor is light and compact. It can be shed

in a twinkling and packed away in his kit.

Except under the most strenuous battle con-

ditions, when ease of movement is para-

mount, it is worn with comfort.

The adoption of body armor by the In-

fantry, just announced by the Ordnance

Department, means two things: fewer and

less serious wounds, and fewer replacements

of troops on the battlefield.

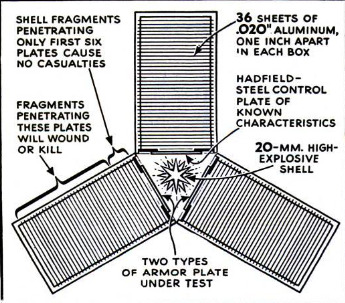

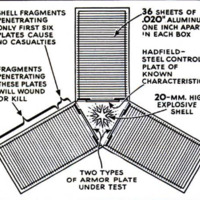

Eight percent of all battlefield casualties,

and half the deaths, are caused by shell

fragments (sometimes erroneously called

shrapnel). When the bursting charge of a

high-explosive shell detonates, the steel pro-

jectile is shattered into thousands of frag-

ments which are thrown unevenly over an

area proportionate to the size of the shell.

These fragments vary widely in size and

shape. Some are dustlike particles of steel;

others are jagged slivers weighing a small

traction of an ounce; comparatively few are

larger chunks of metal. They are projected

from the bursting shell at a speed of about

3,000 feet a second, but they lose velocity

quickly and seldom are traveling over 1,500

feet a second when they strike. No body

armor light enough for a soldier to wear can

protect him against a direct hit by a high-

explosive projectile, or even from sizable

fragments from a burst close to him, but

the body armor being supplied to our men

can and does protect them against a large

majority of fragments.

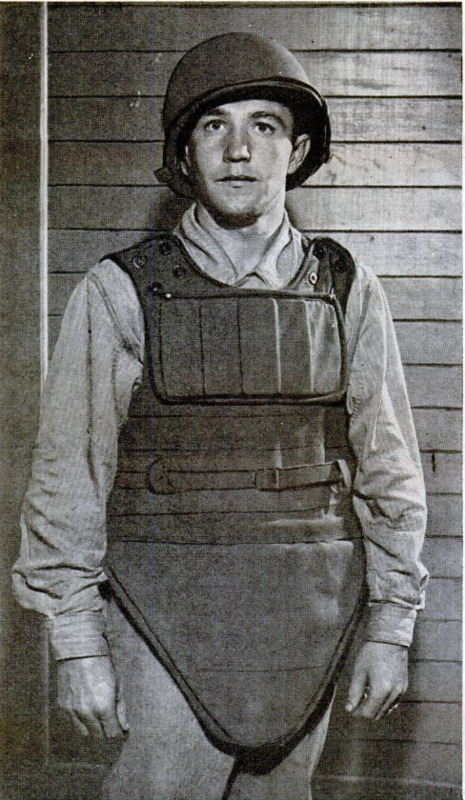

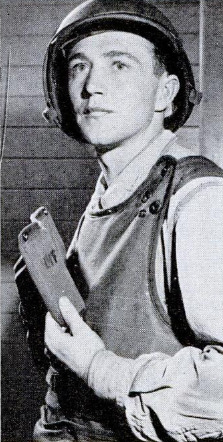

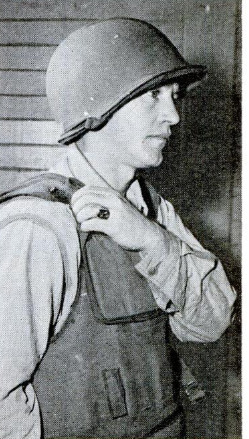

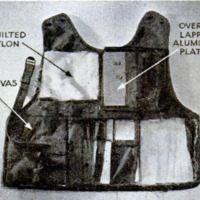

The GI's armor is designed specifically to

stop most shell fragments from penetrat-

ing the skin. Most wounds occur in the

torso. That's the area the armor protects.

Body armor is not new in this war. Bomb-

er crews have been using it in the form of

“flak suits.” These are easy to wear be-

cause a man in a bomber doesn’t move

around much. Armor for the warrior with

only his own feet for mobility is something

else again. It has to be light. It has to

leave his movements unrestricted. It has

to be styled so that it can be doffed in-

stantly in an emergency.

Army Ordnance produced just that kind

of armor. Ordnance went further. By a

series of painstaking tests it determined

how much velocity the little pieces of metal

plate, backed by quilted pads of multiple-

layer nylon, would stop. While the infan-

tryman’s armor is considerably lighter than

that in a flak suit, it is similar in design.

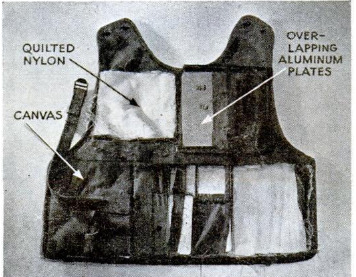

It is a vest weighing 12 pounds that af-

fords protection for both the front and the

back of the soldier. The vest consists of

aluminum-alloy plates measuring three by

five inches—lighter than manganese steel

but equally resistant—backed by the nylon

pads. Shell fragments that penetrate the

plates either are stopped or their velocity is

greatly retarded by the nylon fibers. Hit a

pillow with your fist. Feel it yield reluctant-

ly. That's what happens when a shell frag-

ment penetrates the armor metal and hits

the fabric.

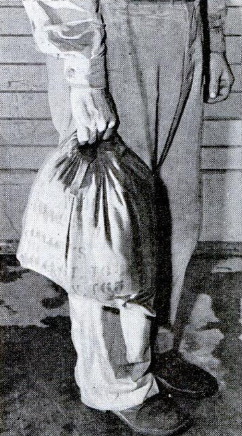

To the vest is attached a small, flexible

apron, weighing only a pound and a half

and also made of quilted nylon, that pro-

tects the lower half of the abdomen.

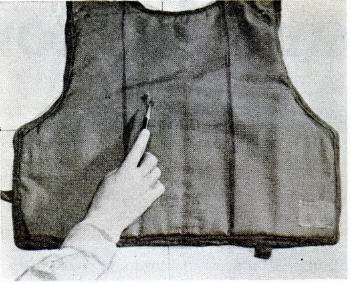

A jerk on two shoulder straps instantly

jettisons both pleces. Vest and apron may

be folded compactly and carried in a pack.

A man jumping from a foxhole and legging

it across terrain under fire doesn't want

to be encumbered. But a man standing in

a landing barge and preparing to hit the

beach, and even one crossing a beach under

a hail of bullets and artillery shell frag-

ments, finds his body armor the shield and

buckler of modern war.

In the development of infantry armor,

Ordnance went directly to the experience

tables of the Air Forces for information.

The Eighth Air Force made the first at-

tempts to protect its flyers against the frag-

ments of flak bursts in 1943 when strategic

bombing was being stepped up in the face

of determined opposition by German fight-

ers (armed with cannon as well as machine

guns) and antiaircraft batteries. Casual-

ties among bomber crews were becoming

serious.

A type of body armor had been developed

for infantrymen in World War I but it was

too heavy to permit a man to move as fast

as he had to in combat. The Eighth Air

Force modified one of the 25-year-old suits

and placed orders for a limited quantity.

They worked. Casualties dropped 60 per-

cent.

Then samples were sent home to Ord-

nance. Col. Rene R. Studler, chief of the

Small Arms Development Division, was

given the job of improving the suit and

getting it ‘into quantity production. He

found that while it often was saving its

wearer from death and wounds, it did show

a lot of holes from shell fragments. Colonel

Studler pondered that one. Then he made

a decision that was to have a profound ef-

fect on body-armor design. It was this:

the number of holes produced could be dis-

regarded. It was what the shell fragments

did after they made the holes that was im-

portant.

Apparatus for testing body-armor ma-

terial was devised and installed at Aber-

deen Proving Ground, Maryland. From

what was learned in detonating explosives

statically an improved flak suit was con-

structed. It was only a step from a better

flak suit to an infantryman’s armor.

Pilot models for body armor, and for

steel helmets as well, are made just where

you would imagine they would be made—in

the armor shop of the one place in the

United States where an intimate study of

devices for protecting the body against

wounds has been carried on for many years.

It is New York's Metropolitan Museum of

Art. The Museum contains magnificent

samples of armor going back to the times

of the ancient Greeks and Romans. Some

of the models are fashioned with the same

kind of planishing hammers as were used to

repair the dented steel harness of King

Richard the Lion-Hearted, back in the days

of the Crusaders.

Improvement of all body armor, includ-

ing that used by flyers, is going on all the

time. Two standard vests for airmen, made

of overlapping two-inch-square plates of

Hadfield manganese steel in fabric pockets

attached to a backing of nylon canvas, now

are being produced. One of them, worn by

bomber navigators, bombardiers, and gun-

ners, weighs 17% pounds, and protects both

the front and the back of the wearer's torso.

The other, worn by pilots and copilots

whose backs are protected by armor-plate

seat backs, weighs 7% pounds and protects

only the front of the body. Pilots and others

who normally remain seated during flight

wear groin armor which weighs 15% pounds

and gives maximum protection to the abdo-

men and thighs. Other crew members wear

either of two models of armor aprons, one

of which weighs about seven pounds and

the other about five pounds. The pieces

making up the various protective combina-

tions are attached to one another by quick-

release fasteners which are connected by a

rip cord. A single jerk frees the wearer.

One innovation now being tested in serv-

ice is flyers’ armor that combines an in-

creased area of protection with an im-

portant decrease in weight.

Seventeenth-century military men who de-

cided that improvements in firearms had

made armor a useless and dangerous en-

cumbrance must be stirring uneasily in their

graves.

-

Contributor (Dublin Core)

-

Arthur Grahame (article writer)

-

William W. Morris (photographer)

-

Hubert Luckett (photographer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1945-09

-

pages (Bibliographic Ontology)

-

73-77,234

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

-

Marco Bortolami (editor)

Popular Science Monthly, v. 147, n. 3, 1945

Popular Science Monthly, v. 147, n. 3, 1945

Screenshot 2023-02-03 114713.png

Screenshot 2023-02-03 114713.png Screenshot 2023-02-03 114724.png

Screenshot 2023-02-03 114724.png Screenshot 2023-02-03 114738.png

Screenshot 2023-02-03 114738.png Screenshot 2023-02-03 114749.png

Screenshot 2023-02-03 114749.png Screenshot 2023-02-03 114801.png

Screenshot 2023-02-03 114801.png Screenshot 2023-02-03 114812.png

Screenshot 2023-02-03 114812.png Screenshot 2023-02-03 114822.png

Screenshot 2023-02-03 114822.png Screenshot 2023-02-03 114833.png

Screenshot 2023-02-03 114833.png Screenshot 2023-02-03 114843.png

Screenshot 2023-02-03 114843.png