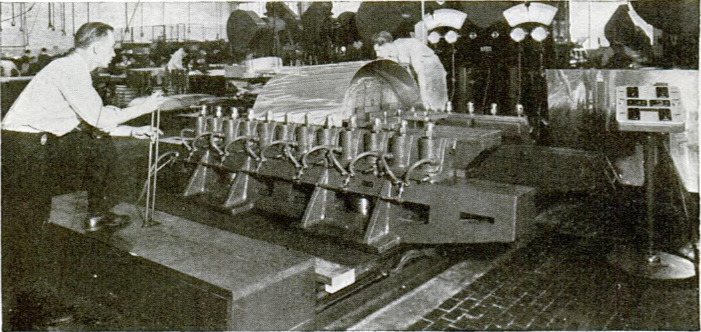

Sheet Metal Stretched to Form Airplane "Skin"

Item

- Title (Dublin Core)

- Sheet Metal Stretched to Form Airplane "Skin"

- Article Title and/or Image Caption (Dublin Core)

- Sheet Metal Stretched to Form Airplane "Skin"

- Language (Dublin Core)

- eng

- Temporal Coverage (Dublin Core)

- World War II

- Date Issued (Dublin Core)

- 1940-06

- Is Part Of (Dublin Core)

-

Popular Mechanics, v. 73, n. 6, 1940

Popular Mechanics, v. 73, n. 6, 1940

- pages (Bibliographic Ontology)

- 890

- Rights (Dublin Core)

- Public Domain (Google digitized)

- Source (Dublin Core)

- Google books

- References (Dublin Core)

- Glenn L. Martin Company

- Archived by (Dublin Core)

- Enrico Saonara

- Alberto Bordignon (Supervisor)

- Spatial Coverage (Dublin Core)

- United States of America