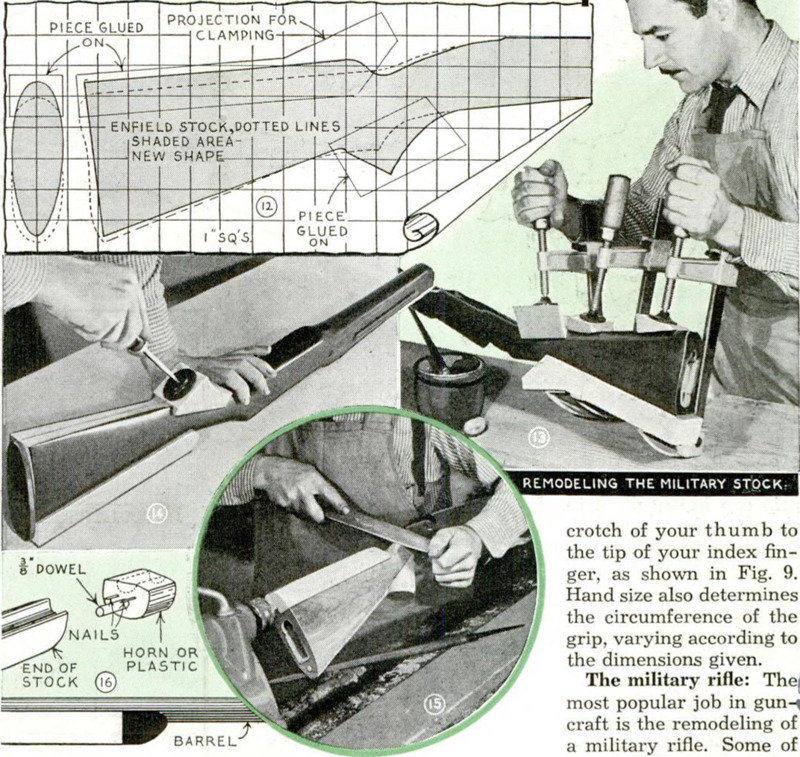

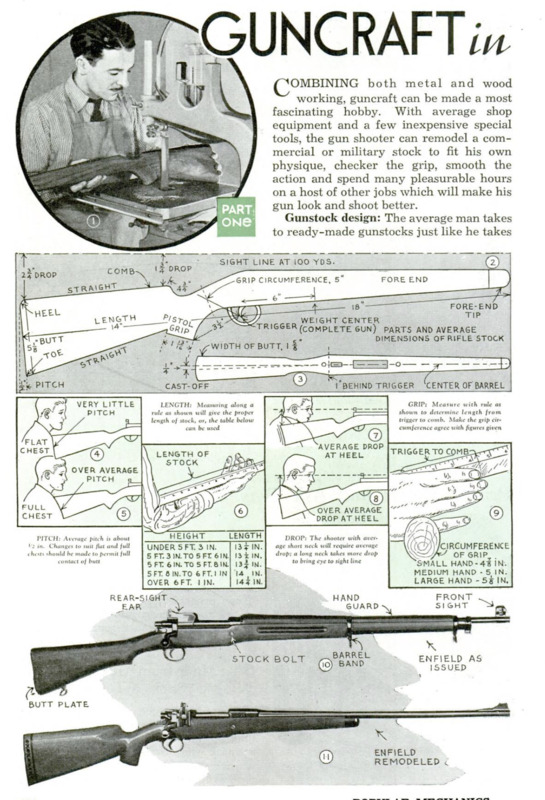

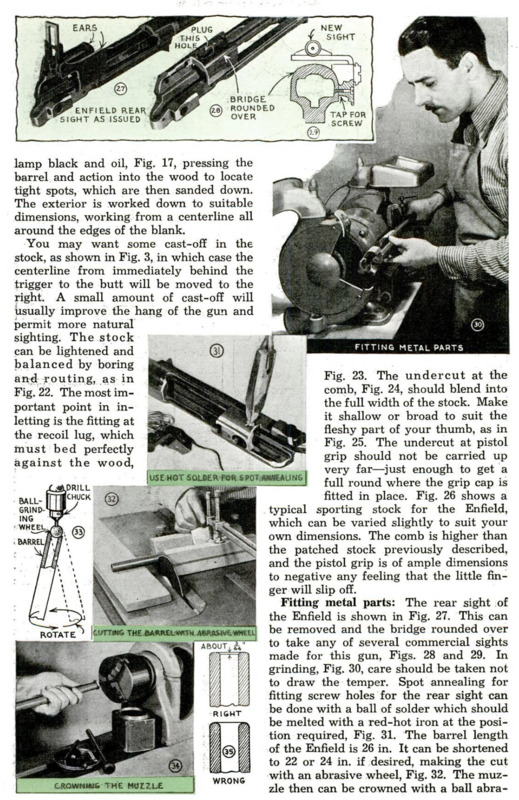

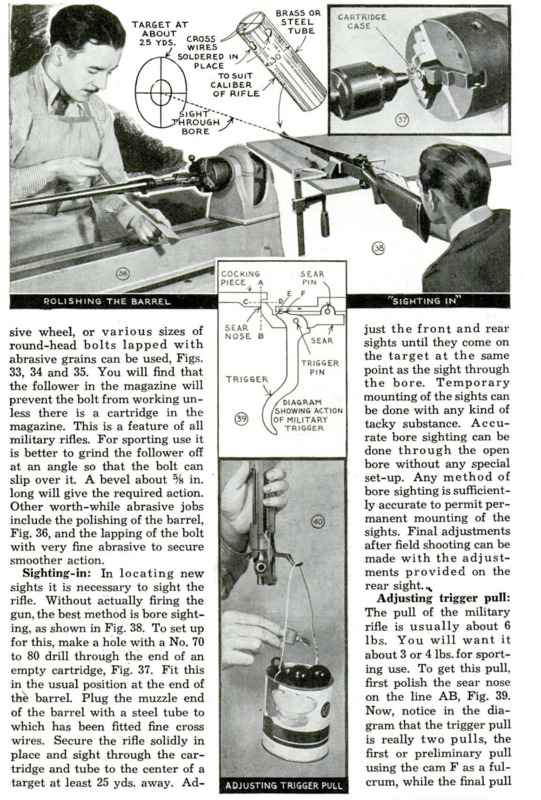

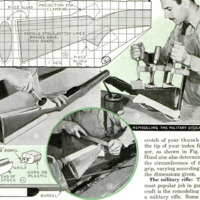

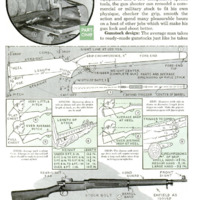

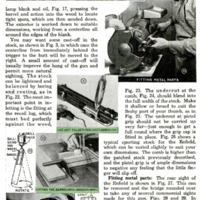

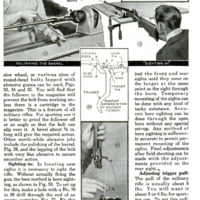

COMBINING both metal and wood working, guncraft can be made a most fascinating hobby. With average shop equipment and a few inexpensive special tools, the gun shooter can remodel a commercial or military stock to fit his own physique, checker the grip, smooth the action and spend many pleasurable hours on a host of other jobs which will make his gun look and shoot better. Gunstock design: The average man takes to ready-made gunstocks just like he takes to ready-made clothes - the fit is fairly good but not perfect. Fig. 2 gives the dimensions of the average rifle stock. If you have a flat chest, you will want a stock with very little or no pitch; if you have a full chest, you will want more than average, Figs. 4 and 5. From bent elbow to middle of index finger measured along a rule, Fig. 6, will give you the length your stock should be from trigger to center of butt. The man with a short neck will require average drop at the heel of the stock, Fig. 7, while the man with long neck and sloping shoulders, Fig. 8, will require much more drop at this point. The distance from trigger to point of comb will average 4% in., but you will get a personal fit if you make this distance the same as from the crotch of your thumb tothe tip of your index finger, as shown in Fig. 9. Hand size also determines the circumference of the grip, varying according to the dimensions given. The military rifle: The most popular job in guncraft is the remodeling of a military rifle. Some of these can be purchased as low as three dollars. One of the best of the low-priced guns is the U. S. Enfield, modelof 1917, which can be obtained from the Director of Civilian Marksmanship, Washington, for less than ten dollars. This gun as issued is shown in Fig. 10, while Fig. 11 shows a typical remodeling job, making it a high-power sporting rifle. Other military rifles which usually can be found for sale include the U. S. Springfield, the Russian Nagant, the British Lee Enfield, Canadian Ross, ete. All are bolt-action rifles. Remodeling the military stock: You can improve greatly the appearance of any military rifle such as the U. S. Enfield by revamping the stock. This is done by gluing on pieces of matched walnut, as shown in Figs. 12 and 13, and then dressing the stock. Fig. 14 shows a new butt plate and pistol grip cap being fitted to the patched stock. Mount the stock in a lathe for rasping to shape, Fig. 15, using a dowel screwed in the barrel groove to hold the stock in the chuck. Final sanding can be done with a belt on the band saw, Fig. 1. Cut the fore end of the stock at any suitable distance and cap the end with a fore-end tip of horn or plastic, Fig. 16. Inletting and shaping: If you want to do a really nice job on a rifle, make a completely new stock. The best way of doing this is to purchase a blank that is already inletted to take the barrel and action. Shaping this to your own dimensions takes a lot of “elbow grease,” but is not at all difficult. Figs. 18 to 21 inclusive show various stages of the stock in the making. Blanks are usually cut about %2 in. undersize and final bedding of the action and barrel is done by coating these parts with lamp black and oil, Fig. 17, pressing the barrel and action into the wood to locate tight spots, which are then sanded down. The exterior is worked down to suitable dimensions, working from a centerline all around the edges of the blank. You may want some cast-off in the stock, as shown in Fig. 3, in which case the centerline from immediately behind the trigger to the butt will be moved to the right. A small amount of cast-off will usually improve the hang of the gun and permit more natural sighting. The stock can be lightened andbalanced by boring and routing, as in Fig. 22. The most important point in inletting is the fitting at the recoil lug, which must bed perfectly against the wood, Fig. 23. The undercut at the comb, Fig. 24, should blend into the full width of the stock. Make it shallow or broad to suit the fleshy part of your thumb, as in Fig. 25. The undercut at pistol grip should not be carried up very far - just enough to get a full round where the grip cap is fitted in place. Fig. 26 shows a typical sporting stock for the Enfield, which can be varied slightly to suit your own dimensions. The comb is higher than the patched stock previously described, and the pistol grip is of ample dimensions to negative any feeling that the little finger will slip off. Fitting metal parts: The rear sight of the Enfield is shown in Fig. 27. This can be removed and the bridge rounded over to take any of several commercial sights made for this gun, Figs. 28 and 29. In grinding, Fig. 30, care should be taken not to draw the temper. Spot annealing for fitting screw holes for the rear sight can be done with a ball of solder which should be melted with a red-hot iron at the position required, Fig. 31. The barrel length of the Enfield is 26 in. It can be shortened to 22 or 24 in. if desired, making the cut with an abrasive wheel, Fig. 32. The muzzle then can be crowned with a ball abra sive wheel, or various sizes of round-head bolts lapped with abrasive grains can be used, Figs. 33, 34 and 35. You will find that the follower in the magazine will prevent the bolt from working unless there is a cartridge in the magazine. This is a feature of all military rifles. For sporting use it is better to grind the follower off at an angle so that the bolt can slip over it. A bevel about % in long will give the required action. Other worth-while abrasive jobs include the polishing of the barrel, Fig. 36, and the lapping of the bolt with very fine abrasive to secure smoother action. Sighting-in: In locating new sights it is necessary to sight the rifle. Without actually firing the gun, the best method is bore sighting, as shown in Fig. 38. To set up for this, make a hole with a No. 70 to 80 drill through the end of an empty cartridge, Fig. 37. Fit this in the usual position at the end of the barrel. Plug the muzzle end of the barrel with a steel tube to which has been fitted fine crosswires. Secure the rifle solidly in place and sight through the cartridge and tube to the center of a target at least 25 yds. away. Adjust the front and rear sights until they come on the target at the same point as the sight through the bore. Temporary mounting of the sights can be done with any kind of tacky substance. Accurate bore sighting can be done through the open bore without any special set-up. Any method of bore sighting is sufficiently accurate to permit permanent mounting of the sights. Final adjustments after field shooting can be made with the adjustments provided on the rear sight. Adjusting trigger pull: The pull of the military rifle is usually about 6 lbs. You will want it about 3 or 4 Ibs. for sporting use. To get this pull, first polish the sear nose on the line AB, Fig, 39. Now, notice in the diagram that the trigger pull is really two pulls, the first or preliminary pull using the cam F as a fulcrum, while the final pull uses point E as a fulerum. Grind a little metal from point E to shorten the final pull, and carefully polish the metal at this point together with the surface on which it operates. When you have finished with this, test the trigger pull with weights, as shown in Fig. 40, and you will probably find it is down to about 4 Ibs. Some gunsmiths reduce the pull by grinding the sear nose on line CD. However, unless you understand fully what you are doing, it is best to leave the metal alone at this. point since any reduction in the shoulder length also decreases the safety factor.

Popular Mechanics, v. 74, n. 4, 1940

Popular Mechanics, v. 74, n. 4, 1940