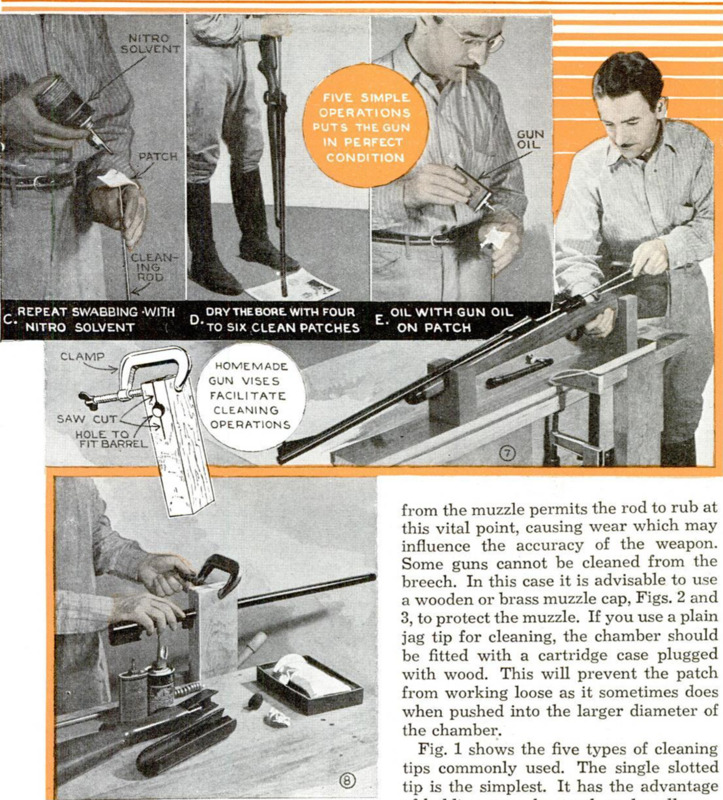

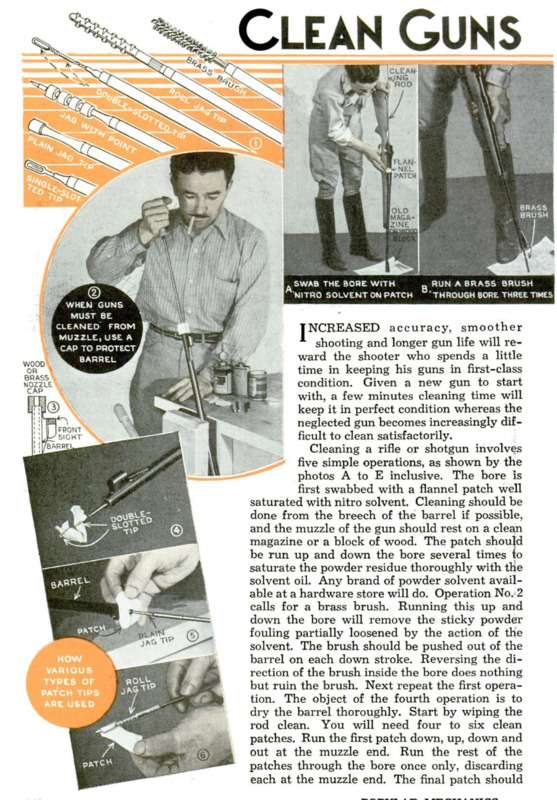

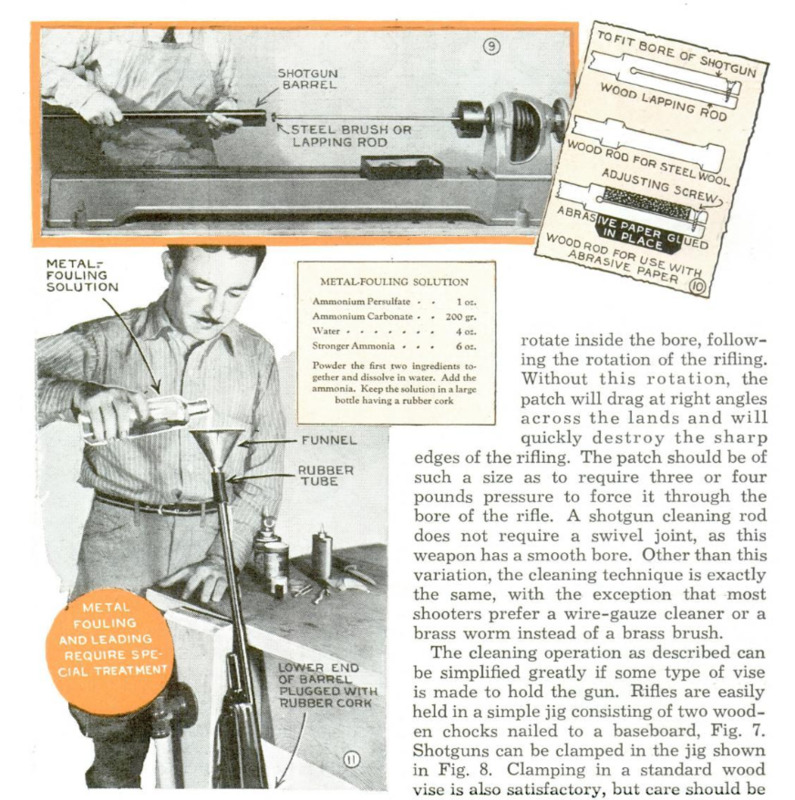

INCREASED accuracy, smoother shooting and longer gun life will reward the shooter who spends a little time in keeping his guns in first-class condition. Given a new gun to start with, a few minutes cleaning time will keep it in perfect condition whereas the neglected gun becomes increasingly difficult to clean satisfactorily. Cleaning a rifle or shotgun involves five simple operations, as shown by the photos A to E inclusive. The bore is first swabbed with a flannel patch well saturated with nitro solvent. Cleaning should be done from the breech of the barrel if possible, and the muzzle of the gun should rest on a clean magazine or a block of wood. The patch should be run up and down the bore several times to saturate the powder residue thoroughly with the solvent oil. Any brand of powder solvent available at a hardware store will do. Operation No.2 calls for a brass brush. Running this up and down the bore will remove the sticky powder fouling partially loosened by the action of the solvent. The brush should be pushed out of the barrel on each down stroke. Reversing the direction of the brush inside the bore does nothing but ruin the brush. Next repeat the first operation. The object of the fourth operation is to dry the barrel thoroughly. Start by wiping the rod clean, You will need four to six clean patches. Run the first patch down, up, down and out at the muzzle end. Run the rest of the patches through the bore once only, discarding each at the muzzle end. The final patch should show perfectly clean and dry. If it shows dirt, the preceding operations must be repeated. The final operation is oiling. This is done with a clean patch. Use any good gun oil. This will protect the gun for a period of four to eight weeks. If the gun is to be stored for a longer period than this, use gun grease instead of the lighter oil. As previously mentioned, cleaning should be done from the breech. Cleaning the gun from the muzzle permits the rod o rub at this vital point, causing wear which may influence the accuracy of the weapon. Some guns cannot be cleaned from the breech. In this case it is advisable to use a wooden or brass muzzle cap, Figs. 2 and 3, to protect the muzzle. If you use a plain jag tip for cleaning, the chamber should be fitted with a cartridge case plugged with wood. This will prevent the patch from working loose as it sometimes does when pushed into the larger diameter of the chamber. Fig. 1 shows the five types of cleaning tips commonly used. The single slotted tip is the simplest. It has the advantage of holding onto the patch under all conditions, but has two disadvantages in that the patch sometimes jams when reversed inside the bore, and, the cleaning action is often one-sided, permitting the bare sides of the tip to rub the bore. The plain jag tip gives a uniform cleaning action, and reverses perfectly inside the barrel. The patch sticks to the tip as long as it is inside the barrel, but any chance movement beyond the muzzle or chamber will cause it to come loose. The same applies to the jag tip with point. The point is an advantage in centering the patch previous to insertion in the bore. The double-slotted tip is a first-rate cleaner, with a uniform action. The roll jag permits rolled or wrapped patches, and is preferred by many shooters on this account. The patch is wrapped around the jag as shown in Fig. 6, and can be made tight or loose as desired. Fig. 5 shows how the plain jag is used, the patch simply being centered on the tip, while Fig. 4 shows the obvious way of using either the single or double-slotted tip. The cleaning rod itself can be brass or steel and should be of a proper diameter to fit the bore of the rifle. It must be fitted with a swivel joint so that the patch will rotate inside the bore, following the rotation of the rifiing. Without this rotation, the patch will drag at right angles across the lands and will quickly destroy the sharp edges of the rifling. The patch should be of such a size as to require three or four pounds pressure to force it through the bore of the rifle. A shotgun cleaning rod does not require a swivel joint, as this weapon has a smooth bore. Other than this variation, the cleaning technique is exactly the same, with the exception that most shooters prefer a wire-gauze cleaner or a brass worm instead of a brass brush. The cleaning operation as described can be simplified greatly if some type of vise is made to hold the gun. Rifles are easily held in a simple jig consisting of two wooden chocks nailed to a baseboard, Fig. 7. Shotguns can be clamped in the jig shown in Fig. 8. Clamping in a standard wood vise is also satisfactory, but care should be exercised in exerting too much clamping pressure. Other than powder fouling, the shooter must sometimes give consideration to metal fouling. This is a deposit of metal left by the bullet in the bore. If you shoot lead bullets, the fouling is more specifically designated as “leading.” It is obvious that a perfectly smooth, polished bore will pick up very little metal fouling, whereas the roughened, neglected bore will always foul to a greater extent. Metal fouling in itself does no particular harm to the bore, but it may trap powder residue beneath it, leading to corrosion of the bore. Metal fouling can be detected by a careful examination of the bore, in which the fouling will show as long streaks, flaky deposits or even actual lumps of metal sticking to the lands and grooves. The fouling is easily removed, if attended to promptly, by using the metal-fouling solution specified in Fig. 11. The liquid is kept in a tightly corked bottle at all times except when actually using the solution, since it loses strength quickly when exposed to air. This can be applied with a cloth patch in the usual manner if the deposit is light. For a more thorough action, the solution is poured into the bore of the gun after first plugging the chamber with a rubber cork. When first poured in, the solution will be as colorless as water but will assume a deep blue color as it begins to dissolve the metallic deposit. The action is complete in about 15 min. Care should be taken in using the metal-fouling solution as it will remove bluing or the finish on the stock. After the solution has been removed from the barrel, the regular cleaning procedure should follow immediately. Leading can be removed with the metal-fouling solution. Many shooters, however, prefer mercury. A few ounces of this are placed in the barrel. A finger over the muzzle will hold it inside, and a few tips up and down will cause the mercury to amalgamate with the lead deposit. The solution can be used many times. Mercurial ointment is a satisfactory remedy for leading as is also common vinegar or a dilute solution of glacial acetic acid. Metal fouling in shotgun barrels or any condition of rusting or pitting can be removed usually by mechanical methods as the smooth bore permits almost any type of polishing. The cleaning operation is most conveniently done in a lathe, mounting the polishing barrel or abrasive in the lathe and holding the gun barrel in the hands, as shown in Fig. 9. Steel brushes and polishing heads for this purpose can be purchased, or the shooter can make his own, as in Fig. 10, to be used with paste abrasive, steel wool or abrasive paper.

Popular Mechanics, v. 75, n. 2, 1941

Popular Mechanics, v. 75, n. 2, 1941