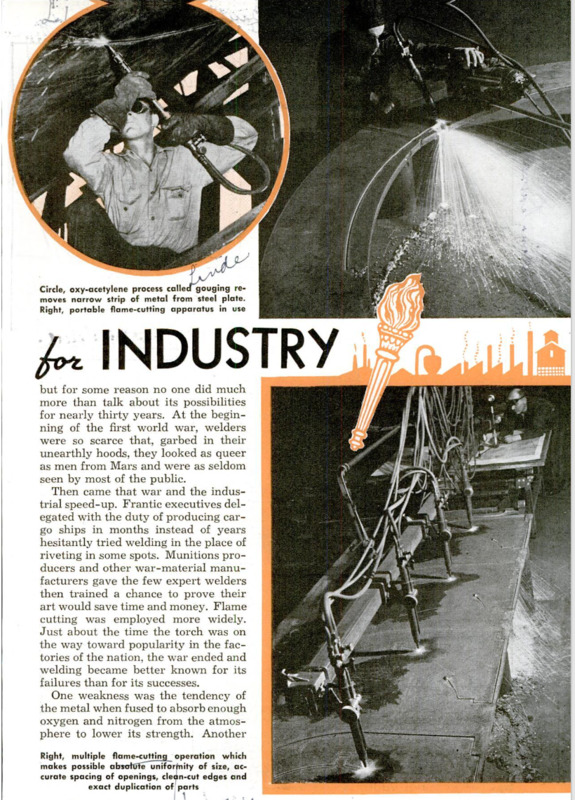

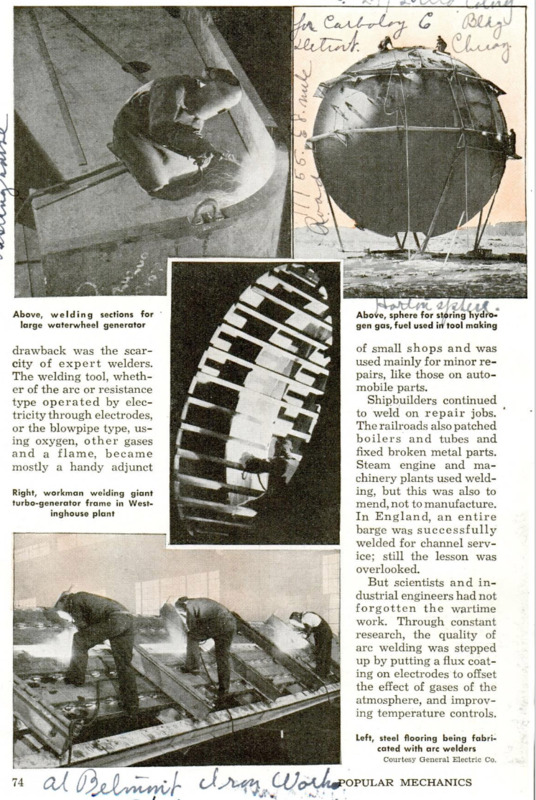

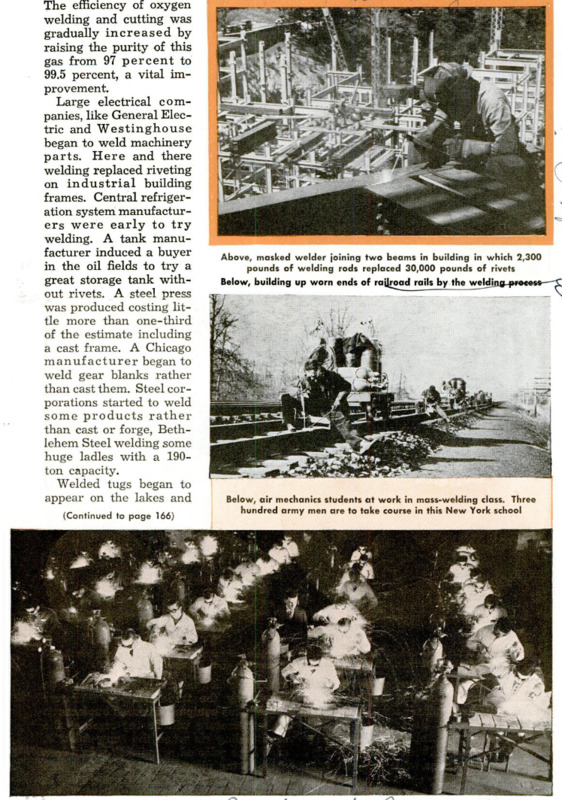

BORN during the excitement of the first world war were two of the most important industrial twins that ever joined the huge family of mechanical devices and methods which constitutes America’s mass production system. These twins, welding and flame cutting, have grown so steadily and quietly during the generation between conflicts that not until the United States started to prepare for defense in recent months did the nation begin to realize how much the husky pair have changed the industrial picture. In the factories, arsenals, shipyards and steel plants of the country today they are literally carrying the torch for industry, lighting the way toward the goal of preparedness. Strangely enough, the art of electric resistance welding was discovered and demonstrated early in the year 1886 but for some reason no one did much more than talk about its possibilities for nearly thirty years. At the beginning of the first world war, welders were so scarce that, garbed in their unearthly hoods, they looked as queer as men from Mars and were as seldom seen by most of the public. Then came that war and the industrial speed-up. Frantic executives delegated with the duty of producing cargo ships in months instead of years hesitantly tried welding in the place of riveting in some spots. Munitions producers and other war-material manufacturers gave the few expert welders then trained a chance to prove their art would save time and money. Flame cutting was employed more widely. Just about the time the torch was on the way toward popularity in the factories of the nation, the war ended and welding became better known for its failures than for its successes. One weakness was the tendency of the metal when fused to absorb enough oxygen and nitrogen from the atmosphere to lower its strength. Another drawback was the scarcity of expert welders. The welding tool, whether of the arc or resistance type operated by electricity through electrodes, or the blowpipe type, using oxygen, other gases and a flame, became mostly a handy adjunct of small shops and was used mainly for minor repairs, like those on automobile parts. Shipbuilders continued to weld on repair jobs. The railroads also patched boilers and tubes and fixed broken metal parts. Steam engine and machinery plants used welding, but this was also to mend, not to manufacture. In England, an entire barge was successfully welded for channel service; still the lesson was overlooked. But scientists and industrial engineers had not forgotten the wartime work. Through constant research, the quality of arc welding was stepped up by putting a flux coating on electrodes to offset the effect of gases of the atmosphere, and improving temperature controls. The efficiency of oxygen welding and cutting was gradually increased by raising the purity of this gas from 97 percent to 995 percent, a vital improvement. Large electrical companies, like General Electric and Westinghouse began to weld machinery parts. Here and there welding replaced riveting on industrial building frames. Central refrigeration system manufacturers were early to try welding. A tank manufacturer induced a buyer in the oil fields to try a great storage tank without rivets. A steel press was produced costing little more than one-third of the estimate including a cast frame. A Chicago manufacturer began to weld gear blanks rather than cast them. Steel corporations started to weld some products rather than cast or forge, Bethlehem Steel welding some huge ladles with a 190-ton capacity. Welded tugs began to appear on the lakes andcoastal waters. The frame of a 200-inch telescope was welded. Station KDKA in Pittsburgh was given an electric arc-welded antenna 718 feet high. Germany built an all-welded 10,000-ton pocket battleship. Items like this attracted public attention from time to time, but it was not until the present industrial emergency came that the nation began to realize that the strong right arm of production held a torch. Today, warships are very largely welding jobs, as are merchant hulls and entire barges and tugs. In fact, practically all of the vessels under 300 feet in length now in production in the United States are welded. There is a saving in weight, time and cost up to 15 percent, according to welding authorities, depending upon conditions. The same is true of stationary and marine boilers and tanks used in oil refineries and chemical plants, as well as those used for water and other liquid storage. Spot welding of airplane parts, such as wings and fuselages and gas welding of high-tensile plane tubings is common, yet it is a comparatively recent development. Tanks, gun mounts, recoil mechanisms, anti-aircraft gun carriages, gasoline and oil trucks, tractor parts, railroad freight and passenger cars, electric locomotives, automobile frames, giant shovels, hoists and derricks, refrigerators, and even articulated, streamline trains form just a short, suggestive list of familiar products of the welding arc and blowpipe. Among the more novel applications is the welding of entire bridge floors. Another is the welding of piles. Preparing the foundation of a large mid-western factory building, a foundation company drove 8,600 steel piles into the earth. As each 30-foot section of the 18-inch square, ¥2-inch thick pipe was driven into the earth, another section was hoisted into position and arc-welded onto it, until the pipes penetrated more than 100 feet. Then 12-inch H-beams 108 feet long were driven into them and concrete was poured. Increased use of welding has resulted in improvement and improvement has brought about increased use, until the expert welder of the first world war would find himself a novice today unless he hadmodernized his technique. Aside from arc welding with covered electrodes and oxyacetylene welding with high-temperature flame, some of the newer developments are spot and line welding in which an electrical resistance is set up at special points to bind two sheets of metal together; atomic hydrogen welding, for high quality work; thermit welding in which iron oxide and aluminum are set off with a magnesium ribbon creating a flowing liquid alloy; brazing, which uses such alloys as phosphor-copper and silver-copper for fine jobs on thin metals, and the union-melis electric process which gives remarkable speed with no flash, glare or smoke. Mechanized welding is giving efficiency to line production by the use of semi-automatic controls. Flame-cutting, used during the first world war principally to reduce scrap, has now become a precise art and is rapidly edging aside shearing and forging. Steel three feet thick can be flame-cut by blowpipes with an accuracy of about 1/1000th of an inch and this renders possible cutting of plates prior to fabrication on such jobs as shipbuilding or tank making. A novel use is for cutting the teethlike, interlocking expansion joints used on most modern bridges. The blowpipe is also valuable in wrinkle-bending of pipe, one side of which can be softened so the pipe can be shaped on the spot before being laid. Hard facing of metals by applying super hard alloys, such as stellite, flame hardening of a small section of a large piece of metal and flame cleaning of the surface of castings is a modern development. Stack cutting in which a number of layers of metal can be sliced through at a time and pattern devices which make the cutting process semiautomatic are increasing the value of the oxygen-using blowpipe. The gouging process removes a narrow strip of metal from steel plate, forgings and casting. The deseaming process “washes” away surface defects from slabs and billets. The descaling process removes scale from metal surfaces. The oxygen lance makes short work of very heavy cuts when aided by the oxy-acetylene blowpipe. So the torch of industry, whether it joins together by welding, or puts asunder, by flame-cutting, is becoming a more complicated device as it becomes more refined.

Popular Mechanics, v. 76, n. 1, 1941

Popular Mechanics, v. 76, n. 1, 1941