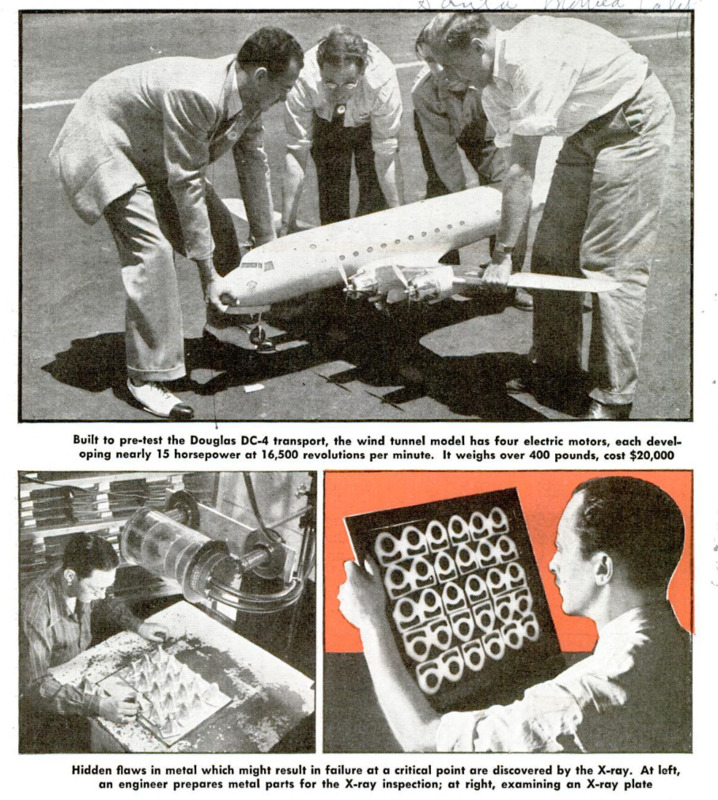

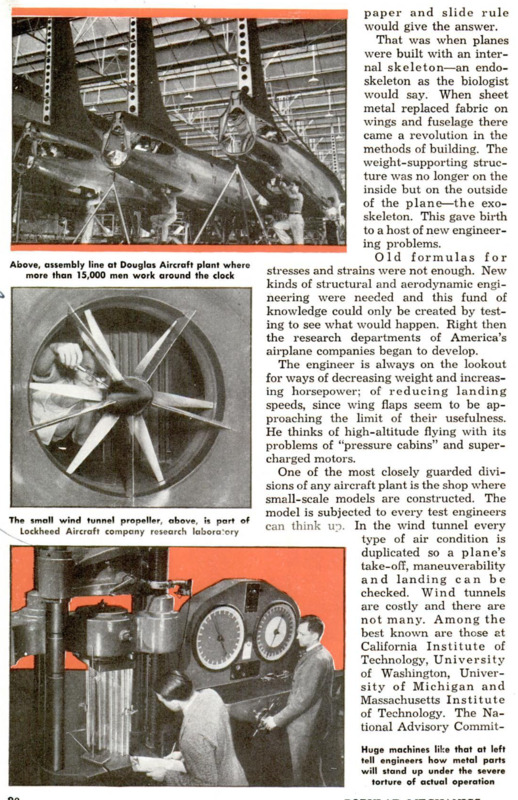

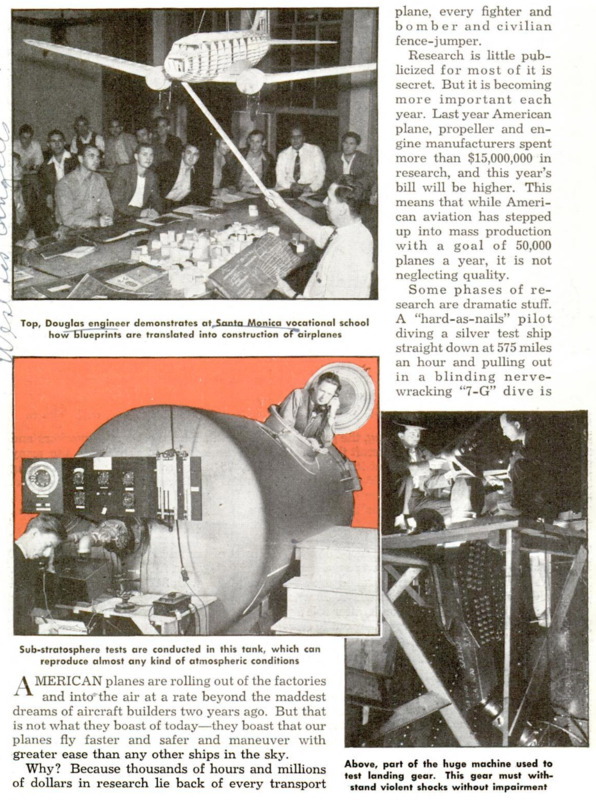

AMERICAN planes are rolling out of the factories and into"the air at a rate beyond the maddest dreams of aircraft builders two years ago. But that is not what they boast of today - they boast that our planes fly faster and safer and maneuver with greater ease than any other ships in the sky. Why? Because thousands of hours and millions of dollars in research lie back of every transport plane, every fighter and bomber and civilian fence-jumper. Research is little publicized for most of it is secret. But it is becoming more important each year. Last year American plane, propeller and engine manufacturers spent more than $15,000,000 in research, and this year's bill will be higher. This means that while American aviation has stepped up into mass production with a goal of 50,000 planes a year, it is not neglecting quality. Some phases of research are dramatic stuff. A “hard-as-nails” pilot diving a silver test ship straight down at 575 miles an hour and pulling out in a blinding nerve-wracking “7-G” dive is dramatized by the movies and the fiction magazines. But the major part of research is slow, patient, cold and scientific. It consists of engineers over drafting boards, of craftsmen building models, of skilled mechanics with delicate testing machines. Planes and parts are subjected to “torture tests” to prove their dependability. Some of these tests are performed in the air, but for the most part they take place in the laboratory. Ten years ago airplanes were built on the general principles of a bridge or a skyscraper. Engineers knew approximately what load a certain type of structure could carry. A few minutes figuring with pencil, paper and slide rule would give the answer. That was when planes were built with an internal skeleton - an endoskeleton as the biologist would say. When sheet metal replaced fabric on wings and fuselage there came a revolution in the methods of building. The weight-supporting structure was no longer on the inside but on the outside of the plane - the exoskeleton. This gave birth to a host of new engineering problems. Old formulas for stresses and strains were not enough. New kinds of structural and aerodynamic engineering were needed and this fund of knowledge could only be created by testing to see what would happen. Right then the research departments of America’s airplane companies began to develop. The engineer is always on the lookout for ways of decreasing weight and increasing horsepower; of reducing landing speeds, since wing flaps seem to be approaching the limit of their usefulness. He thinks of high-altitude flying with its problems of “pressure cabins” and supercharged motors. One of the most closely guarded divisions of any aircraft plant is the shop where small-scale models are constructed. The model is subjected to every test engineers can think u». In the wind tunnel every type of air condition is duplicated so a plane’s take-off, maneuverability and landing can be checked. Wind tunnels are costly and there are not many. Among the best known are those at California Institute of Technology, University of Washington, University of Michigan and Massachusetts Institute of Technology. The National Advisory Committee for Aeronautics maintains wind tunnels and research facilities at Langley Field in Virginia and Sunnyvale Field in California. The U. S. Army has extensive laboratories at Wright Field. And finally, several of the large aircraft manufacturers have their own wind tunnels. Test piloting still has its place in the development program, but today’s test pilot is not the legendary daredevil. He has to be an engineer because he must know mnot only what a plane will do but why. The old-fashioned way of testing was to build a new plane and see what happened in the air. Today the engineers tell how it will perform by looking at the laboratory statistics. That's why “torture tests” are more important today than test piloting. Static testing utilizes vast machinery and delicate instruments. Wing sections are pulled apart in huge presses, fuselage sections are twisted and landing gears are dropped. Gasoline tanks are shaken until seams split. Rivets are broken, metal is twisted like rubber. Whole planes, sitting in jigs, are loaded as if power diving in a tornado. If the planes “can take it” in the laboratory, the engineers know they will stand up in a storm over the Rocky Mountains or a dogfight over London. Full-sized sections of planes are attached to huge test columns capable of withstanding 2,500,000 inch-pounds of pressure. With a complex set of hydraulic jacks the section can be put under compression, torque, shear and tension - each stress being recorded simultaneously on a set of dials and gauges. New sections are tested with their normal load, then overloaded until something gives way. Since vibration might cause failure of certain parts, vibration tests are important. Special machines have been developed to determine the natural frequencies of various parts to make sure that these frequencies will not correspond with each other or with frequencies of a moving part such as the engine or propeller. Every structure has a frequency at which it will vibrate violently with very little force being exerted upon it - like a piano string which vibrates if a tuning fork of the same pitch is struck nearby. Many airplane parts are given fatigue tests - alternately loaded and unloaded many times until they break, just as a wire is broken when bent back and forth many times. Seats are loaded and unloaded with bars of lead until the springs break; oil lines are loaded and unloaded with oil until they give way; tires are bounced to simulate landings until they are worn out. Hydraulic booster systems undergo rigid tests before they are put to work operating the controls, wing flaps, engine cowlings, bomb doors and landing gear. In the Douglas plant, ten times the expected life of the plane is the standard set for hydraulic parts. In dynamic proof testing (drop tests), landing gear and sometimes whole planes are dropped violently to be certain they retain satisfactory taxiing characteristics. The research group never knows from one day to the next what problem it may be called upon to do. As a purely routine matter they may run tests day after day to determine the tensile strength of steel and aluminum alloys, fabric, plastics, copper and other materials that make up the modern airplane. Such miscellaneous items as bushings, tubing, springs, bearings and cables may be on the test machines. Motors are carefully tested by engine makers. A standard “block test” is to run them for six hours, tear them down for inspection, and then run them for another five and one-half hours. This precaution is necessary to determine if all 5,500 parts of the modern high-specd engine are functioning perfectly. When Douglas recently built the huge B-19 bomber, one of the four 2,200 horse-power Wright Duplex Cyclone engines (the largest ever built) was tested several hundred hours. This ground testing resulted in several minor changes. Research has led to the practice of X-raying vital metal parts. Flaws which are not apparent on the surface are quickly detected in the X-ray machine. One of the largest X-ray machines in the aircraft industry was recently installed at Burbank, Calif, to serve Douglas, Lockheed, Consolidated, Vultee and North American plants. X-raying of parts has eliminated guesswork as to fitness of materials to be used. There have been no structural failures in planes that passed X-ray tests. In addition to constant research and testing on the part of the aircraft manufacturers, each large buyer of planes maintains his own inspectors in the manufacturing plants to see that planes are built according to his standards. Government as well as air line inspectors keep an eye on commercial planes; Army and Navy inspectors observe the production of warplanes. American aviation has passed beyond the “invention” stage and is in the “improvement” stage of development today. For example, Douglas DC-3 planes, first built in 1935, are better planes today than when they rolled out of the factory. New parts have replaced some original parts which have worn out, yet many of these planes have been running for 20,000 hours, and will see many thousands more hours of service. According to Dr. Karl T. Compton, president of the Massachusetts Institute of Technology, ten of America’s aircraft manufacturers spend 10 percent of their gross income on research. This is the secret of American leadership in the air!