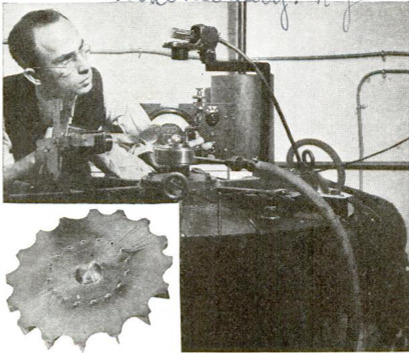

Metal Wheels Spin to Destruction in Test of Bomber Part

Item

- Title (Dublin Core)

- Metal Wheels Spin to Destruction in Test of Bomber Part

- Article Title and/or Image Caption (Dublin Core)

- Metal Wheels Spin to Destruction in Test of Bomber Part

- Language (Dublin Core)

- Eng

- Temporal Coverage (Dublin Core)

- World War II

- Date Issued (Dublin Core)

- 1942-03

- Is Part Of (Dublin Core)

-

Popular Mechanics, vol. 77, n. 3, 1942

Popular Mechanics, vol. 77, n. 3, 1942

- pages (Bibliographic Ontology)

- 49

- Rights (Dublin Core)

- Public domain

- Source (Dublin Core)

- Google books

- References (Dublin Core)

- General Electric

- Archived by (Dublin Core)

- Enrico Saonara