-

Title (Dublin Core)

-

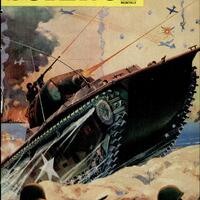

Seagoing shops keep the B-29's pounding Japan

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Seagoing shops keep the B-29's pounding Japan

-

extracted text (Extract Text)

-

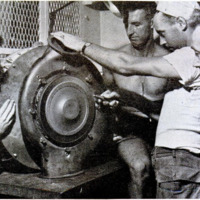

BY BRINGING the repair base to the Su-

perfortress, instead of vice versa, the

timetable of the Pacific war has been

speeded up two to six months. The Army

Air Forces now reveals another of its

schemes for blasting the Japs in their home-

lands—complete repair shops aboard Liberty

ships.

Those floating repair bases simply pull up

alongside a newly captured island and go

directly to work to keep the B-29's in tip-

top shape for their mighty bombing

attacks. They can do just about any-

thing in servicing the 55,000 parts of

the big planes. After there has been

time to establish repair bases on land,

the floating shops pull up anchor and

move on to the next island.

The Liberty ships, which were con-

verted to their mew use by the Air

Technical Service Command, are known

officially as Aircraft Repair Units

(Floating), but the seagoing AAF me-

chanics who work aboard them have

boiled it down to “floater.”

Not only is this new-type ship fitted

with such shops as are needed for its

mission, but it also is equipped with

quarters and mess facilities for its per-

sonnel work, intelligence officer, finance

officer, chaplain, laundry, PX, library,

movies, and a complete hospital.

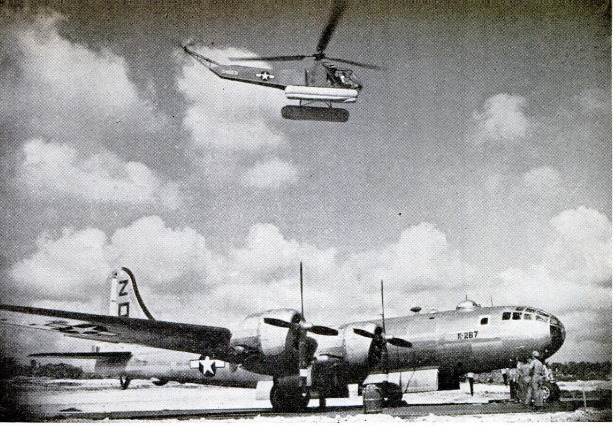

Floaters carry their own local trans-

portation, for use at the scene of operations,

right on their backs. Perched above the

forward portion of the main deck is a 72-

by-40-foot flight deck from which Sikorsky

R-4B helicopters operate. Just aft of the

flight deck are two “ducks” and two jeeps

with trailers. On the fantail are two 30-

foot work boats.

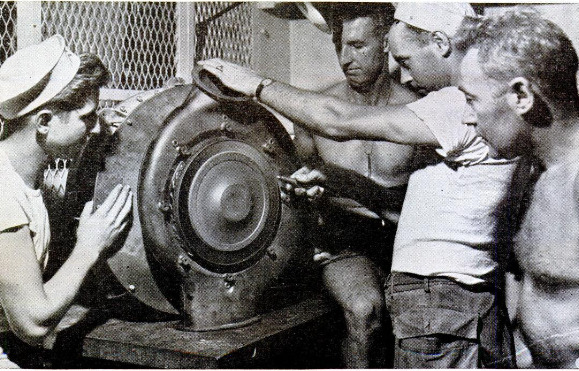

Here's how the floater works: When B-29

operations began in Saipan last November,

the planes were experiencing trouble with

their prop governor heads. A clip which

held a resistor was defective. The vibra-

tion of the engines loosened the clip, and

the resistor, which looks like a cartridge-

type fuse, popped out of the clip, got into

the moving parts of the governor, and some-

times ripped it to pieces.

One of the floaters arrived in Saipan the

day before the first Tokyo raid, and dropped

anchor in Garapan harbor. Tactical outfits at

Iseley Field rushed some 50 damaged prop

governor heads to it for repair. Working

at top speed, robbing some of the beat-up

‘mechanisms for parts, and improvising, the

men of the floater that night had a number

of governor heads in serviceable condition.

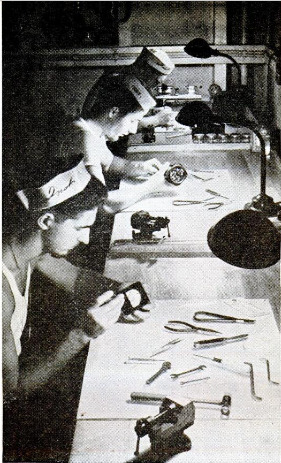

The repair units are equipped with the

following shops: machine shop, welding,

sheet metal, heat treating, electroplating,

ordnance, turret, ground and airborne radar,

radio, camera repair, propeller, carburetor,

turbo-supercharger, electrical, paint-dope-

and-fabric, woodwork, instrument, bomb-

sight, tire, fuel cell, parachute rigging, and

drafting. There is a plant for the generation

of aviators’ breathing oxygen, the largest

mobile plant of this kind overseas.

The B-29's aren't the only customers. The

floaters have done work on P-51's and can

handle work from any other planes, Army

or Navy. One outfit even manufactured

some gears for Seabee bulldozers when the

Seabees were in a jam, and another capped

the tires of a general's staff car.

-

Contributor (Dublin Core)

-

Amos Landman (article writer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1945-09

-

pages (Bibliographic Ontology)

-

91-92

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

Popular Science Monthly, v. 147, n. 3, 1945

Popular Science Monthly, v. 147, n. 3, 1945