-

Title (Dublin Core)

-

Jet-turbine planes the race of the turbo-jets

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Jet-turbine planes the race of the turbo-jets

-

extracted text (Extract Text)

-

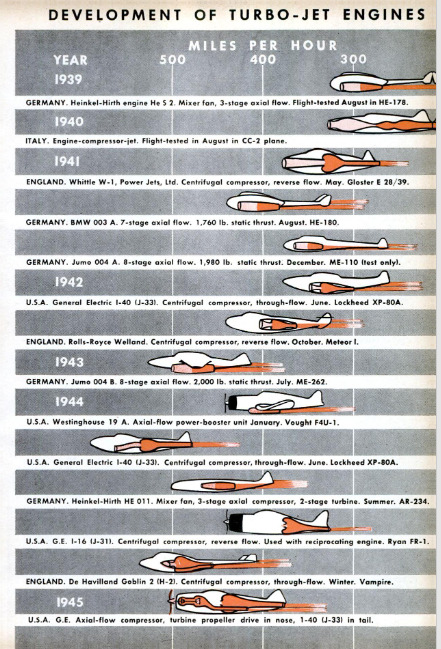

ENGINES that deliver both jet and pro-

peller power have been developed be-

hind the veil of wartime secrecy. While the

atom smashers were tapping a new source

of heat, the aviation engineers were seeking

new, more efficient means of using heat to

fly airplanes—and their discoveries can be

used immediately.

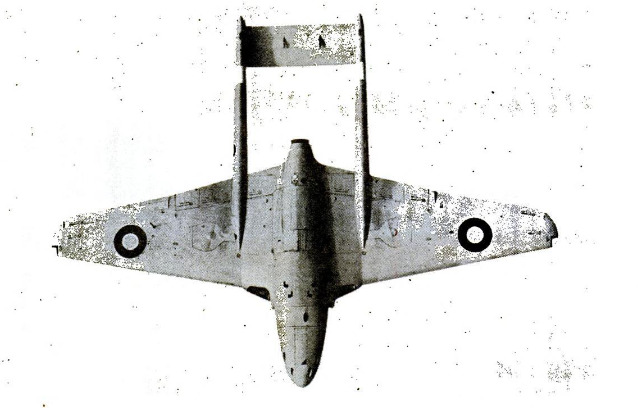

Already, the new-type engine's perform-

ance is being evaluated in an experimental

AAF plane soon to be test-flown. This air-

plane differs from all others in that a gas

turbine both pulls and pushes it through the

air. The P-80 Shooting Star and the British

Vampire are merely jet planes. The Ryan

FR-1 Fireball has a conventional engine in

its nose and a jet engine in its tail. The

new fighter has a gas turbine that twirls a

prop in the nose and a turbo-jet engine that

emits a jet in its tail.

Jet propulsion is such a momentous de- |

velopment that May 14, 1941, the date the |

first British jet fighter flew, already ranks

second in importance in aviation history

only to December 17, 1903, the date of the |

Wright brothers’ first flight. That fighter |

had a W-1 turbo-jet, designed by Frank

Whittle, and was built by Power Jets, Ltd.

It proved that, at long last, airplane speeds

were high enough, heat-resistant alloys were

good enough, and the installed weight of |

power units plus fuel was low enough to

permit the gas turbine's use in aircraft. |

The turbo-jet engine, as is now well

known, operates by pulling in air, compress- |

ing it, and adding heat at high pressure.

Some of the energy resulting from the ex- |

pansion of the combustion products turns |

the turbine that drives the compressor; the |

rest can be ejected through a nozzle at high |

velocities. The reaction to this high-pow-

er discharge of

such a jet will thrust an airplane forward.

Such turbo-jets differ from rocket engines

(P.S.M., May "45, p. 70) in that they rely on

the atmosphere rather than their fuel sup-

ply for oxygen. They are most efficient at

very high speeds and altitudes. At low

speeds and altitudes, too much of their

thrust power is needed to turn the turbine

which pulls in and compresses the air. By

using two gas turbines, however, one to emit

a jet and the other to turn a propeller, air-

craft can be operated efficiently at either

high or low speeds and altitudes. “The gas

turbine,” says Dr. Jerome S. Hunsaker,

head of the department of aeronautical and

mechanical engineering at Massachusetts

Institute of Technology and chairman of

the National Advisory Committee for Aero-

nautics, “gives evidence of being the next

step in the evolution of power plants, com-

parable in its effect on technology to that of

the steam turbine at the turn of the cen-

tury.”

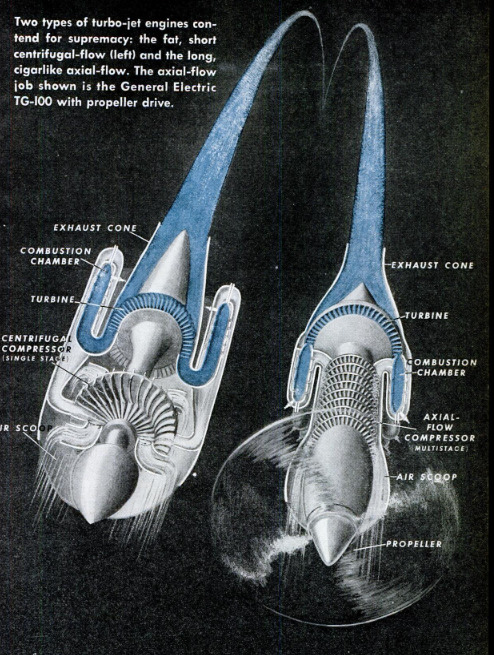

There are two important types of turbo-

jet engines, operating on the same funda-

mental principles but differing in the ar-

rangement of the essential parts. One type

is the centrifugal-flow turbo-jet, and the

other is the aial-flow turbo-jet. The dif-

ference is somewhat analogous to that be-

tween conventional radial and in-line re-

ciprocating engines. A centrifugal-flow

turbo-jet is likely to be short and fat like

a drum, whereas an axial-flow engine may

be long and thin like a cigar.

Centrifugal-flow engines, based on Cap-

tain Whittle's original conception, pull the

air in near the center and whirl it out

toward the ends of the compressor blades.

The rear casing of the air compressor may

have seven, ten or more symmetrical chan-

nels radiating outward, depending on the

number of combustion chambers. These

channels distribute the air to the chambers

where it is mixed with the fuel.

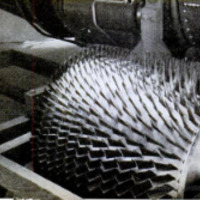

In the axial-flow engines, on the other

hand, the air flows straight through the

five essential parts of a turbo-jet: (1) in-

take duct, (2) compressor, (3) combustion

chamber, (4) turbine, and (5) exhaust noz-

zle. These parts are arranged in a straight

line in axial-flow engines, and compression

is obtained by the action of several sets of

blades rather than by the single-stage ac-

tion usually found with centrifugal flow.

Advocates of centrifugal-flow engines

rightly contend that greater power per

pound of the engine weight has been ob-

tained thus far from engines of this type

than from axial-flow engines. The latter,

however, being smaller in diameter, are

cleaner aerody-

namically and better suited for installation

in high-speed aircraft.

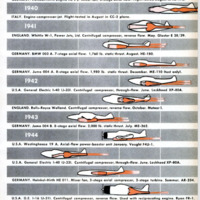

‘The Germans concentrated almost wholly

on development of axial-flow engines—and

came dangerously close to winning the be-

hind-the-scenes battle of the aeronautical

engineers. Ernst Heinkel, one of their most

versatile engineers, and his firm became in-

terested in jet propulsion in the late 1920s;

research work began at the Bavarian Motor

‘Works near Munich in 1934, and at the huge

Junkers works at Dessau in 1937. Test

flights were made with jet planes in Ger-

many before Whittle’s motor was tried in

the British Gloster, although his original

unit was run earlier on test stands.

German plans called for the development

of huge aircraft of the flying-wing type,

powered by turbo-jets. Supersonic aircraft

with ram jets, and accurately controlled,

long-range, guided missiles, were also pro-

jected. Basic research for these machines

was largely completed by the summer of

1945, when Allied technical experts poured

into Germany. Their findings give point to

the Nazis’ boast in 1940 that their military-

aircraft program was well in hand for six

or even eight years to come. They had the

men, the money, and the research facilities,

and came disturbingly close to success.

British engineers at the Royal Aircraft

Establishment had also begun work on axial

compressors and gas turbines in the 1930's,

but it was Whittle's centrifugal-flow type

that really sparked the production program

in England. While the test flights were

being made in 1941, a more advanced Whit-

tle unit, the W/1A, was being run on test

stands—and this engine became the basis of

the first American operational units. :

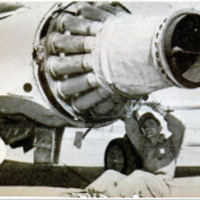

A Whittle engine, built by Rolls-Royce

and called the Welland, powered the British |

Gloster Meteor, the twin-jet fighter that

was used successfully to combat the V-1

flying bombs in the summer of 1944. Mean- |

while, Major F. B. Halford, chief designer

of De Havilland’s aero-motor division, de-

signed a more powerful turbo-jet which be-

came the power plant of the De Havilland

Vampire, Britain's speediest jet fighter, with

a top speed of 540 miles per hour.

Colonel Donald J. Keirn of Wright Field

went to England in the summer of 1941 and |

returned with one of the first Whittle W/1A

units. General Electric then produced the

1-A turbo-jet and greatly improved it as |

the I-16. Its top speed of 414 miles per hour

in the Bell jet fighter was less than that of

the P-47 and P-51 with boosted reciprocat-

ing engines. It was essential that the Allies

have a fighter with a jet speed 100 miles

per hour higher than that. So Wright Field

asked General Electric to produce a larger

and more powerful turbo-jet based on the

Whittle design. At the same time Lock-

heed was asked to design a suitable air-

frame to take a more powerful unit.

As a result of this high-pressure de-

velopment, the XP-80A with GE I-40 turbo-

jet was test-flown in June 1944. This was

the Shooting Star, still the fastest plane in

the air.

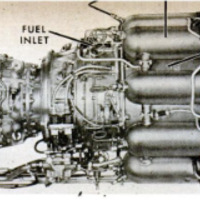

The I-40 turbo-jet is the most powerful

aircraft engine in production. With its mag-

nesium compressor housing, it weighs 1,850

pounds, compared with 828 pounds for the

I-16, and has 14 radially arranged combus-

tion chambers instead of 10. The I-40 em-

bodies the “through-flow” rather than ‘“re-

verse-flow” feature of the I-16, Welland,

and early Whittle designs, and this permits

a diameter only seven inches greater than

that of the I-16. Sea-level static thrust is

2 1/2 times greater than that of the smaller

engine.

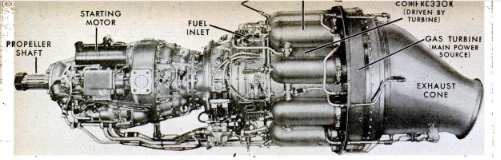

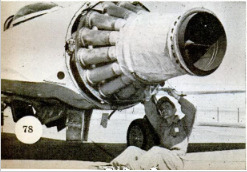

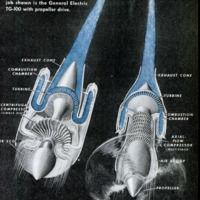

In addition to these developments of cen-

trifugal-compressor-type turbo-jets, a group

of engineers has been working for several

years on the design and development of

axial-flow gas turbines for jet propulsion

and for propeller drive. The first project to

be completed was the unit for propeller

drive, which underwent its first test-stand

run in the spring of 1943. In June 1945, the

first unit was installed in the experimental

fighter mentioned at the beginning of this

article. This is an all-gas-turbine job, with

a propeller turbine in the nose (TG-100,

newly designated XT-8) and a turbo-jet

(I-40, or J-33) in the tail for fast take-off,

accelerated climb, and combat booster

power.

The General Electric axial-flow turbo-jet

unit (TG-180) was developed in 1943, and

was first run on the test stand in April

1944. It is the projected power plant of sev-

eral experimental fighters and bombers that

are well distributed throughout the Ameri-

can aircraft industry. Both this unit and

the gas turbine for propeller drive should

also be suitable for use in long-range trans-

port aircraft.

-

Contributor (Dublin Core)

-

Col. N. F. Silsbee (article writer)

-

Language (Dublin Core)

-

Eng

-

Date Issued (Dublin Core)

-

1945-12

-

pages (Bibliographic Ontology)

-

76-79,234,238

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

Popular Science Monthly, v. 147, n. 6, 1945

Popular Science Monthly, v. 147, n. 6, 1945