-

Titolo

-

Flying engineer

-

Article Title and/or Image Caption

-

Title: Flying engineer

-

extracted text

-

ALL THE DAREDEVILTRY and much

of the risk have been eliminated from

the profession of the test pilot. No longer

is he a nerveless young man who flies by

the seat of his pants and thinks up ingen-

ious methods of risking his life. He is an

engineer as well as a pilot, and makes a

scientific analysis of engine performance in

flight.

Today's test pilot does not start the tests

—he completes them. Before he lifts a new

plane into the air or takes off to try out a

new engine, a remarkably thorough series

of test “flights” has been performed on

drawing boards, in wind tunnels, on engine

blocks, and in pressure chambers. The pilot

is not concerned simply with finding out

whether the equipment will hold together;

his purpose is to confirm under actual flight

conditions the conclusions already reached

by technicians on the ground, or to disclose

some quirk which has remained hidden.

This change in the procedure of testing

has, of course, developed a type of pilot

different in most respects from the adven-

turous youth who formerly did the job. The

careful reading of instruments in current

tests is a far cry from the extensive use of

intuition in the old days.

Herbert V. Shebat, engineering pilot for

the Wright Aeronautical Corporation, Pat-

erson, N. J, is a personification of the con-

trast between the hit-or-miss days and the

methodical procedure of today. Now a test

pilot for one of the world's leading aircraft

engine manufacturers, Shebat studied engi-

neering at the University of Minnesota

before the World War, served with the Army

Air Corps, and was a barnstorming flyer

from 1924 to 1930, when he joined the Wright

organization. Most of his hours in the air

today are devoted to the testing of new

appliances for engines already in produc-

tion, and he has drawn on both his engi- |

neering and flying experience in putting |

Wright's Whirlwind, Cyclone, and Duplex

Cyclone engines through their paces.

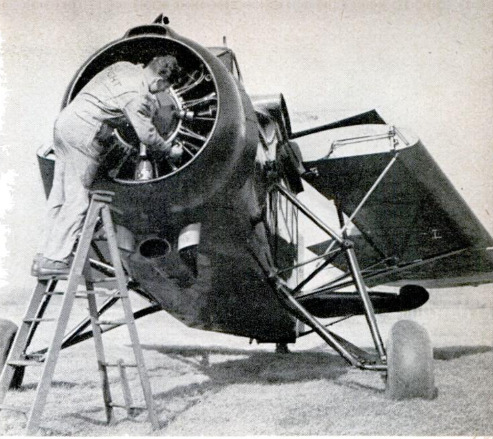

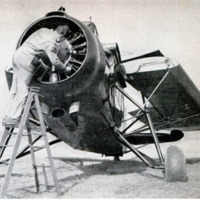

‘Shebat and his coworkers at the Wright

flight-testing laboratory have thelr head- |

quarters at the Caldwell-Wright airport,

near Caldwell, N. J, about nine miles from |

the company’s plants at Paterson. Since the |

function of the laboratory is to test engines

rather than planes, the flying equipment is

curious. It includes a Douglas biplane tor-

pedo bomber built for the Navy five years

ago, a fairly modern Curtiss Hawk 75 pur-

suit borrowed from the Curtiss plant for |

confidential tests, and a ten-year-old Pil-

grim cabin monoplane. All, including the

old Pilgrim, have been flown at more than |

30,000 feet.

Shebat's job is as much varied as his

planes. Today, for instance, he may be

trying out an engine equipped with a new

device for lowering fuel consumption. Fuel |

consumption is computed in terms of pounds

a horsepower hour, and the rate of consump-

tion, guaranteed in most modern engines is

5 pound.

When the engine to be tested is installed

in one of the planes, Shebat's work com-

mences. His task is to establish a basis for

comparison with other engines of the same

horsepower, The most commonly used

standard is the propeller-load curve, com-

puted by making level test runs at specified

altitudes with the propeller in a fixed posi-

tion and with the power output varying on

each run. Then the point is found on each

run where the best performance in horse-

power and speed were produced with the

least fuel consumption.

In computing the propeller-load curve, he

is interested chiefly in the torque indicator,

the tachometer, and the fuel-flow meter.

The torque indicator registers in terms of

inch pounds or foot pounds the force utilized

in turning the propeller shaft at a given

speed. The tachometer shows the number of

revolutions a minute of the propeller, and

the two together give the horsepower at

which the engine is operating. On the in-

strument board the torque indicator is

labeled BMEP, an abbreviation for “brake

mean effective pressure,” or the pressure ex-

erted by the turning shaft on a stationary

gear connected with it by a pinion. The

pressure exerted against the stationary gear

is countered by an equal pressure created

by a pump in the engine, and thus the means

for measurement is provided.

The fuel-flow meter shows, in terms of

pounds an hour, the rate at which the fuel

is being fed into the engine. If Shebat de-

sires more precise information, he may use

the volumeter, which measures a small

quantity of fuel and feeds it to the engine

while the observer times it with a stop

watch, Work of this type has whittled the

rate of fuel consumption to a point far below

that of several years ago.

Some of the work which Shebat does

can be handled on solo flights, but other

experiments may require the assistance

of a crew of three or four. One example

is the successful attempt to reduce engine

vibration. The old Pilgrim was the guinea

pig in this series of tests, and the crew

handled the oscillographs which were con-

nected by pick-ups to various sections of

the plane. Runs were made at different al-

titudes with varying power outputs, and

the vibration was transformed through the

pick-ups into electrical impulses which

passed through a cathode-ray tube and be-

came visible on a screen. The data contrib-

uted to the development of the modern

motor mount, which cuts off from the body

of the plane the vibration of the engine.

Most of the current tests at Caldwell are

conducted at high altitudes, and, as Shebat

will tell you, high-altitude work is “some-

thing that nobody who knows anything

about it likes.” The tests are, of course,

largely confidential, but interest centers in

the development of improved superchargers.

On flights to more than 30,000 feet in an

old open Curtiss Falcon observation plane,

Shebat and his observers discovered data

valuable in developing the two-speed super-

charger, which produces moderate super-

charging in low ratio for full power at

take-off, and high supercharging in high

ratio for flying in rarefied air.

More recently, experiments have been

conducted with a multistage supercharger,

which works on a sort of tandem principle,

with one blower discharging into another.

The chief problem in developing the two-

speed type, Shebat reports, was the main-

tenance of equal pressure in and out of the

engine. It was discovered in early tests

that while pressure was maintained inside

the cylinders, the pressure outside was not

sufficient to insulate the ignition system,

and a spark would jump to a cylinder which

was not ready to fire. The problem was met

by supercharging the magneto, too.

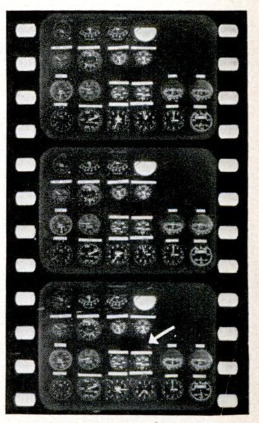

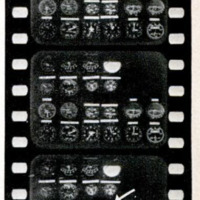

Shebat uses a camera which photographs

the instruments during flights. In all three

planes—provision has been made for the

installation of a French-made Sept camera

which can take either motion pictures or

stills, and after each flight a permanent

record of the performance is available.

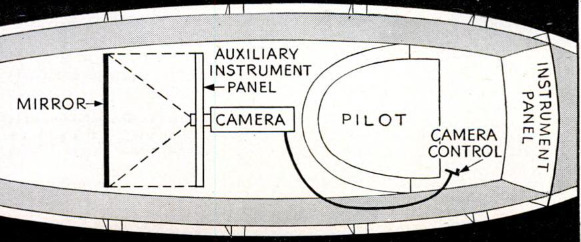

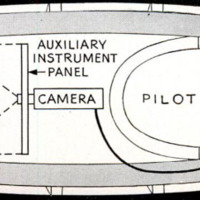

The most interesting camera arrange-

ment is that in the single-seat Hawk, where

the machine has been mounted in a spare

instrument board in the luggage compart-

ment and is operated from the

cockpit by a trigger on the

control stick. Two feet in front

of the spare instrument board

is a mirror with an aluminum

coating, and a reflection of the

instruments is photographed.

The lens is visible as a dark

spot in the center of the board.

The lighting is supplied by

two automobile headlight bulbs

of six volts, mounted above the

board out of the camera range,

and the usual shutter opening

is F/3.5. Shebat reports that

his best results so far were

obtained one day when he used

a bulb exposure without real-

izing it.

In the Douglas, more room

is available in the observer's

cockpit, and the camera is

mounted four feet from the

spare instrument board. To

Keep the two in the correct

position in relation to each

other, they are connected by

metal rods which transmit the

vibration from the board to the

camera. The lighting arrange-

ment is the same as that in the

Hawk. At high altitudes, the

low temperature interfered with

the mechanism of the camera

until an electric heating pad

was wrapped around it.

Shebat’s work is by no means

without risks. Engine failures

have been numerous, but he

has always been able to land

the plane safely. On one flight

near Caldwell, the propeller

and reduction gear dropped off,

but since the airport was only

four miles away and the plane

was 6,000 feet up, he landed.

The lost parts dropped a few

feet from a woman in her gar-

den. She was angry, not be-

cause she had nearly been

killed, but because she was

covered with dirt when the

neighbors came running up.

-

Lingua

-

Eng

-

Data di rilascio

-

1941-04

-

pagine

-

49-51

-

Diritti

-

Public domain

-

Archived by

-

Sami Akbiyik