-

Titolo

-

Latest submachine gun is designed for mass production

-

Article Title and/or Image Caption

-

Title: Latest submachine gun is designed for mass production

-

extracted text

-

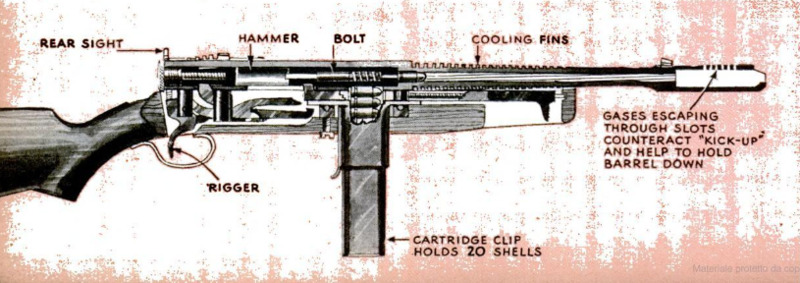

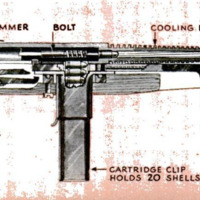

A NEW submachine gun which

shoots .45 caliber automatic

pistol bullets at the rate of

500 a minute is now being turned

out by the Harrington and Rich-

ardson Arms Company, of Worces-

ter, Mass. at the rate of 1,000 guns

a day.

Although in its present form the

gun weighs only 614 pounds as com-

pared with the 9%-pound Thomp-

son submachine gun and the U.S.

Army's new 91-pound Garand ri-

fle, the inventor, Eugene G. Reis-

ing, is confident that eventually he

will cut its weight down close to

the five pounds which the War De-

partment considers ideal for para-

chute troops, air infantry, motor-

cycle riders, and the close-up work

of mechanized units. He is also

adapting it to fire the .30 caliber

carbine cartridge.

Just as important as its light

weight, however, is its simplicity.

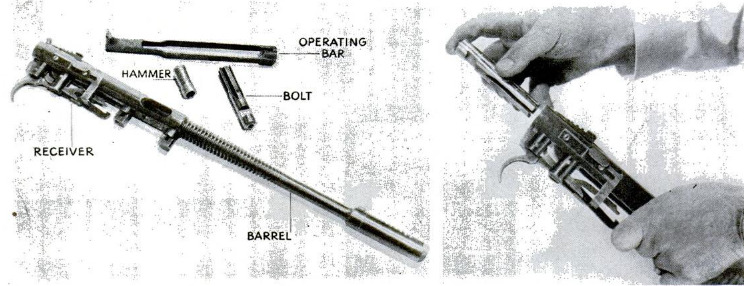

The Reising has only three moving

parts—the hammer, bolt, and ac-

tion bar—compared with eight in

the widely used Thompson (“Tom-

my") gun. According to the Worces-

ter experts, it is easier to make

a complete Reising gun than it is to

turn out any one of the three most

complex parts of a comparable

weapon. Because of the simplicity

of its construction the tolerances of

error allowable in the Reising are

much wider, making it entirely

practical to manufacture the gun

in any machine shop without spe-

cial tools. Actually a large part of

the machine tools being used at the

present time to produce the 1,000

Reisings a day are fifty years old.

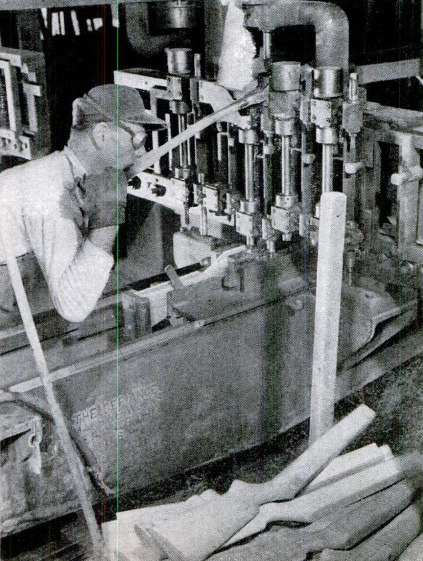

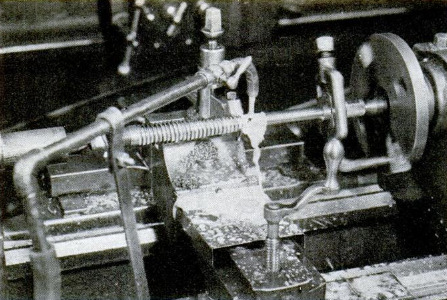

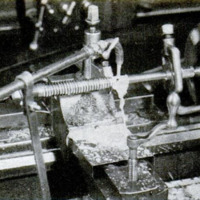

Although special tools are not

required, several are being used to

speed production. Notably, the

Reising barrels are being rified by

the broaching method. Heretofore

gunmakers have rifled barrels by a

process requiring the tool to make

a number of trips through the bar-

rel, cutting the rifling grooves

slightly deeper each time, By

broaching, the 11-inch barrel

of the Reising is rifled in one

trip through, taking only one

minute instead of the old

method's 15 minutes. With

the installation of an auto-

matic lathe, only 12 minutes

will be required to finish a

barrel, from the solid steel

bar to the final bluing.

Simple as it is, the Reising

is capable of grouping a high

percentage of its shots inside

a ten-inch circle at 200 yards,

and that, remember, is with

standard .45 automatic pistol

ammunition. One reason for

this accuracy is the compen-

sator, which is screwed onto

the muzzle like a silencer.

Slots on its top side permit

the gases leaving the muzzle

to expand upward, while a

small shelflike projection on

the under side of the com-

pensator takes a downward

push from the gases, and

these two effects combine to

keep the muzzle down and on

the target, eliminating al-

most all the “jump” of the

muzzle. The recoil, or kick,

also is very slight.

The Reising can be fired

either semiautomatically, one

shot at a time, or automati-

cally at full speed by holding

down the trigger. No hand-

held weapon, of course, can

be as accurate when fired au-

tomatically as when fired one

shot at a time and sighted for

each shot. Also, the short-

ness of the barrel prevents

accuracy equal to a rifle’s. Like most

submachine guns, the Reising has an

effective range of 300 yards.

The .45 caliber bullet leaves the muz-

zle at a velocity of 900 feet a second.

Velocity and the bullet size both figure

in the hitting force and penetrating

power. Rifle and carbine bullets tend to

drill a clean hole through a man, and he

may continue to advance for some yards

after being struck in certain parts of

his body. The .45 caliber slug, on the

other hand, will almost always knock a

man down or spin him around—a val-

uable asset in close-up fighting where

it is necessary to disable the other fel-

low before he can get you.

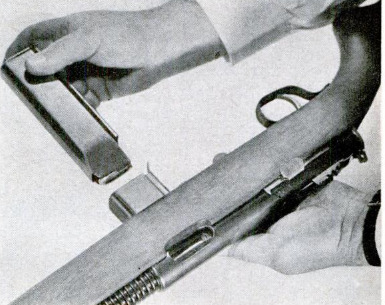

The Reising gun takes a 20-shot clip

magazine, and a 50-round drum can be

adapted to it if wanted. Thanks to its

simplicity, it can be sold for around $85,

or, in military mass production, for $45

to $50, Which is a lot less than the $225

price of a comparable submachine gun

now in wide use.

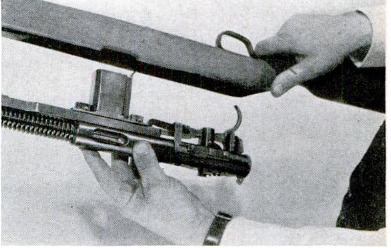

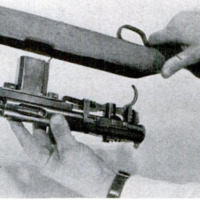

Like the Thompson, the Reising gun

is of the delayed blow-back reloading

type. A pressure of 42 pounds is re-

quired to force the bolt to cam itself out

of a locked position. A shoulder half

encircles the upper part of the bolt; this

fits snugly up against a mating recess

in the upper inside part of the receiver.

These locking parts are milled at an

angle to provide transfer of the reaction

from one plane to another. The re-

action pushes the fired cartridge shell

back until it engages the ejector and is

flipped out. ‘The same movement cocks

the hammer. A retracting spring pulls the

bolt forward; on its way the bolt picks up a

loaded cartridge from the clip and feeds it

into the chamber and then fires it. The

whole takes (at the rate of 500 a minute)

about 3/25 of a second.

Despite its short barrel, the gun has a

sighting radius of 1814 inches. The barrel,

of nickel chrome steel, has cooling fins sim-

ilar to those on the Thompson gun. After

100 rounds rapid fire it is not sizzling hot,

and one of the first Reising guns made has

been fired more than 9,500 times without

any signs of charring the stock and also

without overhauling.

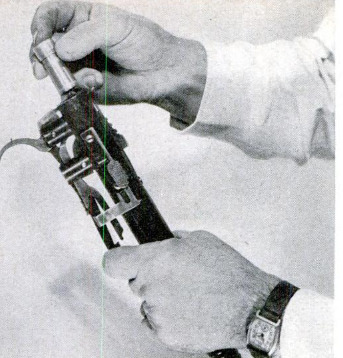

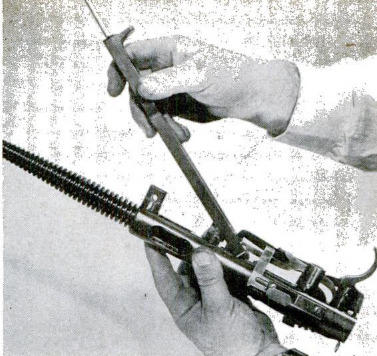

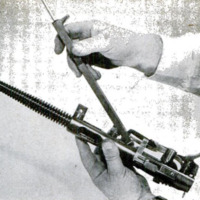

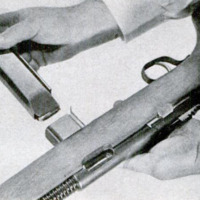

The gun can he taken apart without even

using a cartridge as a tool. Unlike other

submachine guns, it does not have to be lu-

bricated continuously, and Army tests at

the Aberdeen, Md., proving grounds showed

that it could even be fired dry of oil. In these

tests, 3,470 rounds were fired with but two

failures, one due to a defective cartridge

and the other ascribed to incomplete lock-

ing of the breech.

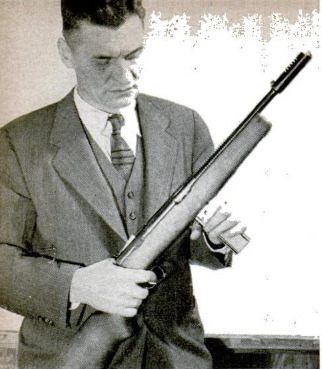

The inventor, Reising (pronounced “Rise-

ing") holds more than 60 patents on pistols

and guns. Many experts consider his .22

caliber automatic pistol the best ever made

in this country. Of Swedish stock that

came to Delaware in 1635, Reising was born

at Port Jervis, N. Y., son of a railroad en-

gineer who died when Eugene was an in-

fant. The boy attended Lehigh University

three years, then punched cattle in Texas

and Mexico a few years. On returning

north, he went to work for Colt, testing and

selling arms. He helped John Browning de-

velop the famed Colt .45 automatic pistol.

Just before the first World War, Reising

designed a simplified machine gun. Later

he designed repeating and automatic rifles

for Mossberg & Sons, Marlin, Savage, and

Stevens. The keynote of nearly all his 30

designs is ease of manufacture.

Besides the U.S. Army, the war depart-

ments of Great Britain, Greece, the Nether-

lands East Indies, Iraq, and several South

American countries have expressed keen

interest in this apparent answer to an

ordnance officer's prayer: a simple, very

light, easily made arm, sturdy, dependable

—that can be turned out in a shop without

costly equipment.—WALTER HOLBROOK.

-

Lingua

-

Eng

-

Data di rilascio

-

1941-04

-

pagine

-

73-76

-

Diritti

-

Public domain

-

Archived by

-

Sami Akbiyik