-

Title (Dublin Core)

-

Wardrobes for soldiers

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Wardrobes for soldiers

-

extracted text (Extract Text)

-

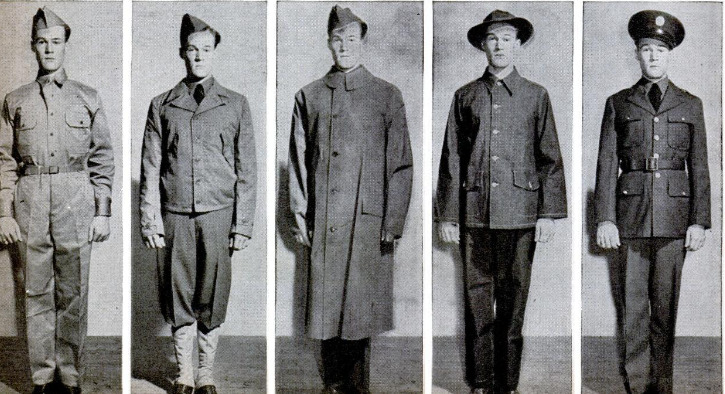

THE busiest haberdashery in the United

States today is the Army Quartermaster

Corps. It has the job of providing uniforms,

complete from underwear to overcoats and

from shoe laces to hats, for the entire en-

listed personnel of the Army.

‘That means a lot more than dealing out

a uniform with two pairs of pants to each

recruit, because the enlisted man in the

American Army is one of the best-dressed

soldiers in the world. He has different uni-

forms for summer and winter, for field work

and garrison duty, for ditch-digging and

parading. Specialists, such as mechanics,

cavalrymen, parachute and armored-force

troops, have, in addition to their

regular uniforms, extra outfits de-

signed to meet their particular

needs.

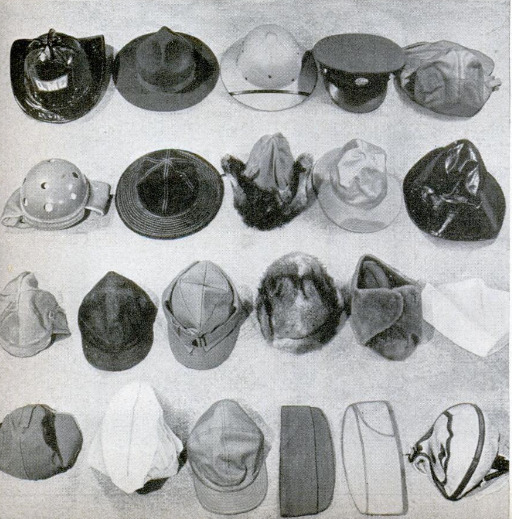

Add the specialized items to the

equipment that is issued to every

doughboy and it makes an impres-

sive list. The office of the Quarter-

master General in Washington, for

example, has samples of 22 kinds

of hats, 17 styles of gloves and mit-

tens, and 15 types of boots and

shoes, representing just a few of

the things that must be kept in

stock to supply the soldiers.

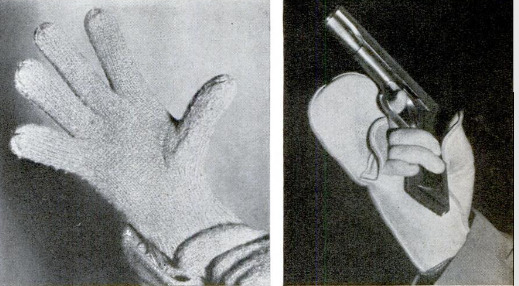

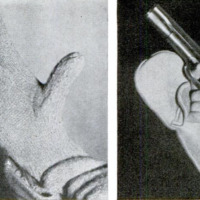

The glove list includes such vary-

ing designs as bearskin mittens for

troops in Alaska, fleece-lined horse-

hide mittens with slits across the

palms so a soldier can get his fin-

gers out to work a trigger without

taking the mittens off, asbestos gloves for

handling hot stuff, suede gloves for Army

nurses, and leather gloves with reénforce-

ments riveted on fingers and palms so

barbed wire can be handled without lacerat-

ing a soldier's hands.

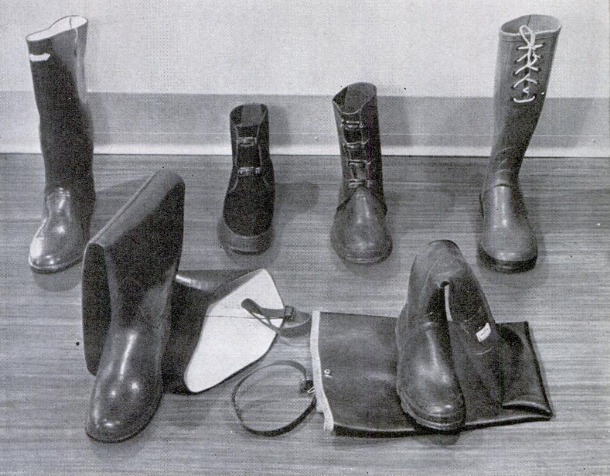

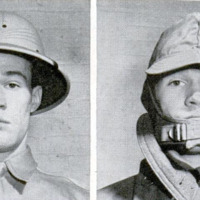

Hats range from headpieces for tank driv-

ers and firemen to cloth-covered fiber hel-

mets for wear in the tropics. Shoes run

from hip boots (two styles) down to oxfords

for the nurses. There is even a special shoe

for Philippine scouts because the ordinary

service shoe doesn't fit their feet.

A list of garments the Q.M. department

‘must keep on hand reads like a mail-order

catalogue. Every soldier

gets, among other things,

woolen shirts and trous

sers for cold weather,

khaki ones for summer,

a wool-lined mackinaw for field work in win-

ter, blue denim trousers and jackets for

dirty work, and a heavy overcoat for “pute

ting on the dog” in cold weather.

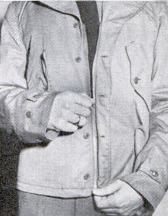

One of the most popular items with the

soldiers is the new lightweight, wool-lined,

wind and water-repellent field jacket. It has

a belted and pleated back, slide fastener and

buttons on the front, and button flaps over

the pockets. The collar can be buttoned

tightly around the neck, or worn open.

‘When the first of these were issued recent-

ly, even the officers wanted some.

However, commissioned officers are

supposed to supply their own cloth-

ing, and the QM. Corps needed all

the jackets it could get for the en-

listed men.

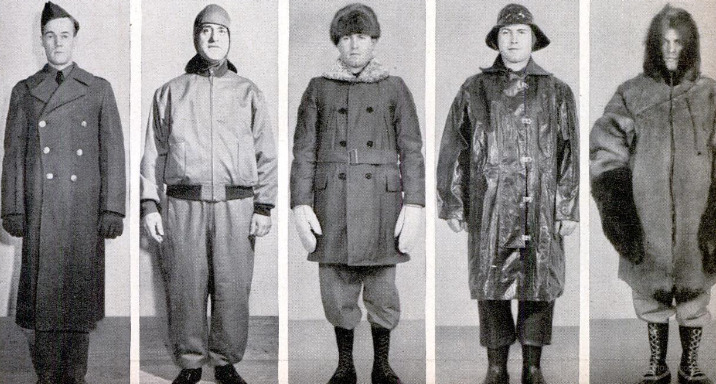

For soldiers in mechanized out-

fits, a “monkey suit” has been de-

veloped that makes a soldier look

like a teddy bear, but does a good

job of keeping him warm and dry.

It is made in two pieces, with over-

all-type trousers and knitted bands

at ankles, wrists, neck, and waist.

Wind and water-repellent cloth are

used for the outer layer, with a

heavy wool lining. A helmet of the

same material, with a flap that ex-

tends down over the jacket collar to

protect the back of the wearer's

neck, and two-buckle arctics, com-

plete the outfit.

Since nothing is available commer-

cially that meets the Army require

ments, the Q.M. Corps develops its

own ideas and those of the Army in

general in designing soldiers’ cloth-

ing. Each of the many garments now

in use represents months, in some

cases years, of experimentation and

research.

The idea for a new type of gar-

ment usually originates in the en-

listed personnel or among the offi-

cers of the Army. When somebody

thinks that a change is in order, he

submits his suggestions to the Q.M.

department. Officers trained in tex-

tile schools, and civilian workers on

the Q.M. staff search the commercial

field for designs and fabrics. Then they

combine what they have found with the

Army suggestions and turn out an experi-

‘mental model. This is submitted to a techni-

cal board in Washington, representing all

branches of the service. If the board ap-

proves, the model goes to the general staff,

and finally to the Chief of Staff for a final

0.K.

After that a trial order is made up and

shipped to some outfit in the field for a

work-out. When the garments have been in

use long enough to see how good they are, a

~ report is submitted to the Q.M. Corps, pos-

sibly with suggestions for improvements.

Then general specifications are drawn up

and manufacturers are invited to bid on

large orders.

Most Army clothing is made by commer-

cial manufacturers from cloth, thread, but-

tons, and fittings supplied by the Army. The

QM. boys know just how many garments

can be turned out from a given amount of

cloth, down to the last yard, and the con-

tractor has to return even the scraps to the

Army after the job is done. These are

weighed and the weight added to that of

the garments to see that nothing is lost.

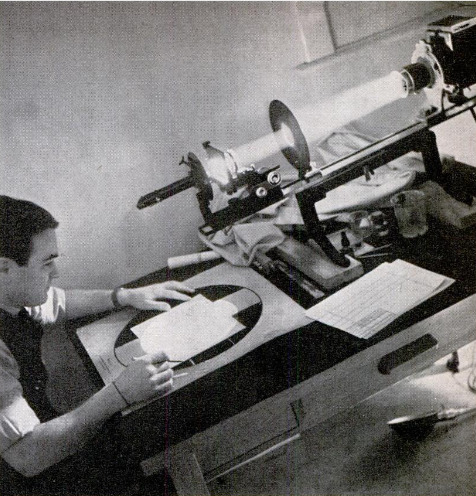

To make sure that it is getting the best

material for its needs, the Q.M. Corps main-

tains at its Philadelphia depot what is prob-

ably the best-equipped textile-testing labor-

atory in the country. There fabrics are

tested for strength, waterproof qualities, and

durability. Thread and cords are checked

for breaking strain, color, and even the

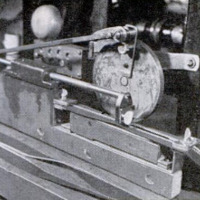

number of yards of thread per spool. Slide

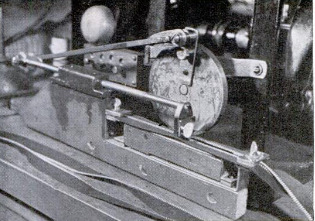

fasteners are hooked to a machine devised

by the laboratory staff and opened and

closed 10,000 times to test them for wear.

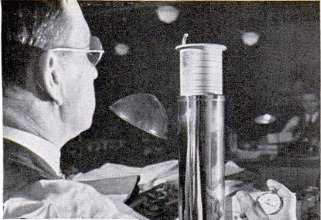

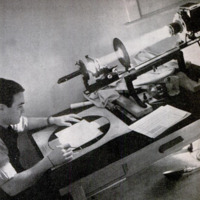

Another ingenious machine developed by

the laboratory staff is used to test the

warmth-retaining characteristics of various

fabrics. It consists of an electrically heated

cylinder around which the cloth is clamped.

The amount of current required to keep the

cylinder at body temperature for a given

period of time while a fan is blowing cold air

against the cloth is measured carefully. By

comparison with cloth which has aiready

been tested in the field, this gives an index

of how effective the new fabric will be.

-

Contributor (Dublin Core)

-

David M. Stearns (article writer)

-

Language (Dublin Core)

-

Eng

-

Date Issued (Dublin Core)

-

1941-06

-

pages (Bibliographic Ontology)

-

90-95

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

Popular Science Monthly, v. 138, n. 6, 1941

Popular Science Monthly, v. 138, n. 6, 1941