-

Title (Dublin Core)

-

America rolls out the warplanes

-

Article Title and/or Image Caption (Dublin Core)

-

Title: America rolls out the warplanes

-

extracted text (Extract Text)

-

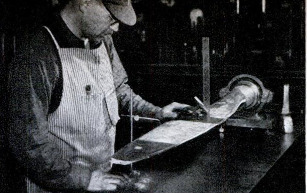

MiLITARY-AIRCRAFT production in the

United States has really begun to go to

town in the last few months. It still has a

long way to go, if it is ever to reach the

50,000 to 80,000-airplanes-a-year output

confidently predicted from time to time.

But it is unmistakably under way and is

constantly gathering both volume and mo-

mentum. In the parlance of flying men,

America’s airplane factories are “rolling out

the tinware,” at an almost incredible rate

considering the few months that have

elapsed since the Government gave them

the go-ahead signal.

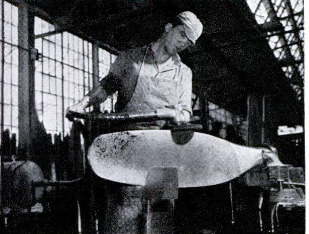

Heavy, four-engined land-plane bombers

for Britain and the United States, that once

took weeks and months to build, and equally

long-range flying-boat patrol bombers, are

coming off the assembly line at the rate of

two a day or better. Shorter-range medium

bombers and still smaller and more ma-

neuverable attack bombers—both in the

two-engine category—are being built at

three or four times this speed. Single-

engined fighters and deadly dive bombers

are being turned out with even greater

rapidity, while training planes of the pri-

mary, basic, and advanced types are being

produced in quantities that, figuratively

speaking, warrant their being wrapped up

in bundles and delivered to their purchasers

in dozen lots.

Periodic surveys made by the Aeronauti-

cal Chamber of Commerce illustrate the

gains made in American warplane produc-

tion since the Government ironed out the

problems of plant expansion, taxes, and

amortization and began placing orders late

last summer and last fall. During Novem-

ber the industry turned out 700 military

planes. In December its output rose to 800;

in January it was 1,000; in March, 1,200;

and in April, 1,427. Col. John H. Jouett,

president of the Aeronautical Chamber,

predicted some time ago that a total of

18,000 planes would be produced during

1941, with 30,000, under present programs,

rolling off the assembly line in 1942. He

said America already was coming ‘‘very

near’ the estimated British and German pro-

duction rates of 1,500 planes a month each. |

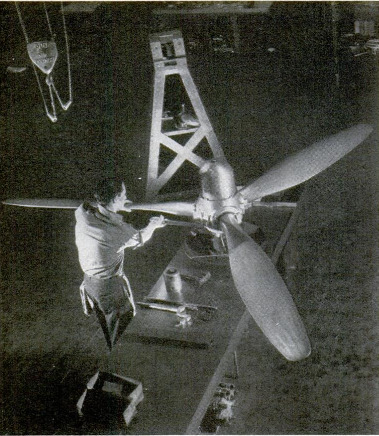

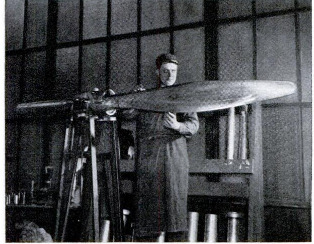

By the end of 1943, it is now estimated

the U.S. will be producing 3,600 planes of

all categories every month. This will also

mean 9,000 engines and propellers monthly.

Some idea of the expansion needed to reach

that capacity may be gained from the fact

that in the eight months preceding March 1,

1941, the industry's floor space increased

82 percent —to 31,383,967 square feet — |

while its total number of employees increased

88 percent to 226,172. And we have another

21; years before we attain the objective

set before us. |

The task actually assigned to this coun-

try’s aircraft industry by defense officials

is to build a total of approximately 44,000

warplanes, including everything from

trainers to four-engined “flying fortresses”

by July 1, 1942. Of these, 16,500 are for |

the Army, 8,500 for the Navy, more than

15,000 for the British, including Canada,

and 3,600 two-engine and four-engine bomb-

ers to be built under the Knudsen plan of

enlisting automotive facilities for the pro-

duction of aircraft. The allocations indi-

cated here have become largely academic

since passage of the lease-lend act; as a

matter of fact, reliable sources in the air-

craft industry report that at one time

about 90 percent of this country’s warplane

production was going to the British.

In view of frequent assertions, some of

them from high places in the Government,

that aircraft production in the national

defense program has been “lagging,” it is

interesting to know what the industry,

through its spokesman, Colonel Jouett, has

had to say for itself. After recapitulating

the ever-increasing number of warplanes

which American manufacturers have been

called on to build, Colonel Jouett, in one

of his recent ‘progress reports” to the

public, said this:

“The immensity of the job can be realized

when I tell you that in 1939 the industry

did $225,000,000 worth of business; in 1940

our people increased their output to $544,-

000,000, at the same time carrying on a

tremendous plant expansion, and that this

year we hope to turn out $1,500,000,000

worth of airplanes.”

There are exceptions, of course, but, on

the whole, the industry maintains that it is

exceeding by a comfortable margin its own

aircraft-production promises—which it dif-

ferentiates sharply from the wishful-think-

ing “production schedules” bandied about

by politicians. It is confident of its ability

to turn out the 44,000 warplanes it has

promised to build by the middle of next

year, but it has an understandable resent-

ment of seeming to be committed (by some-

body else) to a 50,000 or an 80,000-airplane

program—and thereby being put on a spot

with the public when it produces only what

it has undertaken to produce.

The industry is proud of the fact that,

after carefully surveying its facilities at

the beginning of 1939 and telling the Govern-

ment it could produce 5,500 |

military planes a year, it

actually delivered 5,800 ships |

in 1940, Congress having ap-

proved such a construction

program a few months be-

fore the war began. At the

time of the survey, the in- |

dustry’s total output was

about 200 military planes a

month—and its production

had doubled in the preced-

ing year!

Between the outbreak of

the European conflict in Sep-

tember, 1039, and July, 1940,

when this Government offered

the industry financial help in

the plant-expansion program

required to increase produc-

tion, America’s aircraft

‘manufacturers themselves al-

ready had spent $52,000,000

for new factories and equip-

ment, though they estimated

that ‘only $11,000,000 worth

of it will be needed after the

present emergency is over.

This phase of the industry's

expansion program, of course,

was stimulated by warplane

and warplane-engine orders

from the French and British

in their belated effort to

overcome the numerical and

technical superiority of the

Nazi air force. Through it,

the country gained not only

valuable additional facilities

for the production of aircraft

but priceless experience in

the always difficult task of

building and equipping new

plants and training personnel

to operate them without inter-

rupting the flow of existing

production.

Much has been said about

the automotive industry’s

contribution to the American

warplane production pro-

gram. It is, of course, an im-

portant factor and promises

to become increasingly so as time and the

country’s leaders take it on into an un-

certain future.

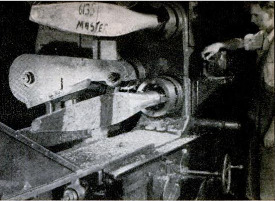

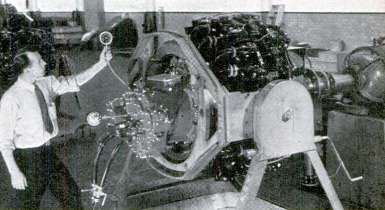

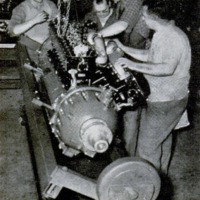

Less than 10 percent of the machine tools

used in automobile plants are said to be

immediately acaptable to manufacture of

the airplane itself—a. relatively simple pro-

duction problem compared with that of an

airplane engine. That is Why the Ford

Motor Company, with its genius in tooling

and production, started from scratch when

it agreed to produce 4,000 Pratt & Whitney

1,850 and 2,000-horsepower radial, air-

cooled engines, under a dollar-an-engine

licensing agreement, and built a brand-new

factory, equipped throughout with new

machine tools.

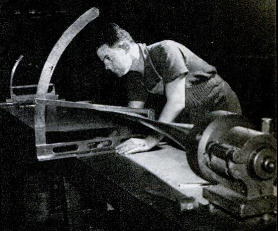

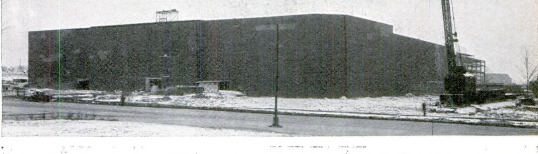

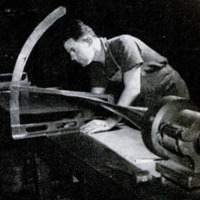

Ford, having also undertaken to fabricate

fuselage, tail surface, and wing sub-assem-

blies of four-motored Consolidated B-24

bombers, in the so-called Knudsen plan to

augment warplane production, also is erect-

ing another new factory specifically de-

signed for this job near Ypsilanti, Mich.

Under the Knudsen

plan, bombers turned

out in semi-finished |

form by Ford and

other automobile

‘manufacturers will be

put together and

equipped with engines

in four huge Govern-

ment-built assembly

plants that are now

under construction at

Omaha, Kansas City, |

Tulsa, and Fort Worth.

This automotive- |

aircraft production

scheme is still to

reach its peak, so far

as output of finished

bombers is concerned.

But there is little

doubt in the aircraft

industry, which has |

been called on for

supervisory personnel

to run the final as-

sembly plants, that

the plan will contrib-

ute materially to the

country’s warplane

production. In addi

tion to long-range,

four-engined Consoli

dated heavy bombers,

these plants are

scheduled to turn out

twin-engined Martin

B-26 and North Amer-

ican B-25 medium

bombers, supplement- |

ing the regular factory output of these three

ships in California and Maryland.

Because of the Government's recent new

accent on heavy-bomber production, ten fac-

tories are scheduled now to produce four-

engined bombers, of which 1,100 are now on

order. Douglas, Consolidated, and Boeing

will each operate two, while Ford, Martin,

North American, and Lockheed will have

one apiece. The combined output of these

ten plants is expected to aggregate 500

monthly, or 6,000 annually, in about a year.

With the B-25 and the B-26, to say noth-

ing of the Consolidated B-24, already coming

off their home-town production lines in sub-

stantial quantities, and the modernized ver-

sion of the original B-17, four-motored “fly-

ing fortress” being turned out ahead of

scheduled delivery dates at Seattle, the

United States is rapidly achieving a well-

rounded program of long and short-range,

land-based air striking power. In the field

of water-borne aircraft, the Navy is looking

after its own long-range bombardment and

scouting needs with the procurement of twin-

engined PBM-1 Martin flying boats and four-

engined PB-2-Y “air dreadnoughts.”

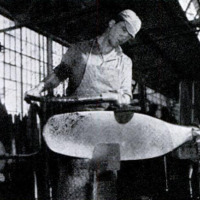

In addition to the production of long and

medium-range bombers, the Army is now

receiving substantial numbers of lighter

and more maneuverable attack bombers,

such as the Douglas A-20 series which is an

American development of the famous DB-T

bombers built first for the French and now

for the British. Sub-assemblies for the

A-20, incidentally, are being fabricated in

Detroit's utomotive plants but this is being

done under contracts foresightedly nego-

tiated by the Douglas company itself, which

have nothing to do with the “Knudsen plan”

of producing 3,600 medium and heavy

‘bombers by the end of 1042. Douglas also

is turning out large numbers of SB-D dive

bombers for the Navy and Marine Corps;

and the Army, abandoning its former lack

of Interest in this type of craft as a result

of the exploits of Germany's Stukas, also

is one of Douglas’ dive-bomber customers.

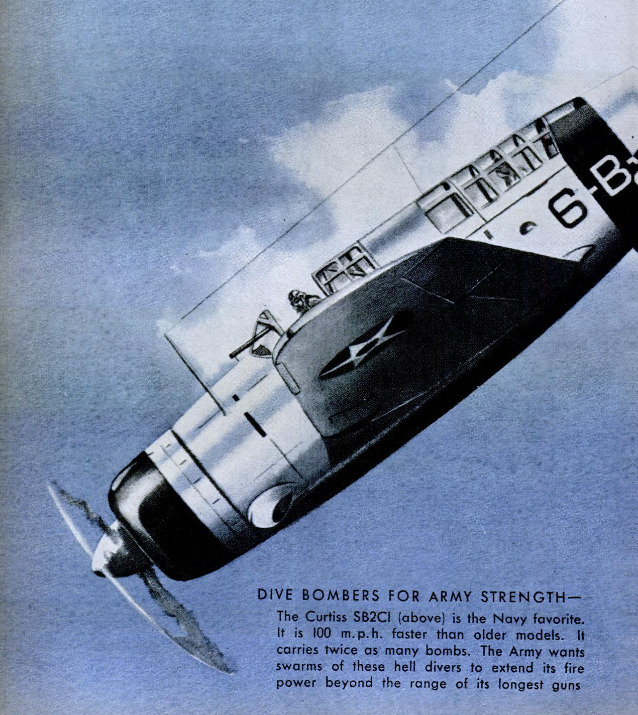

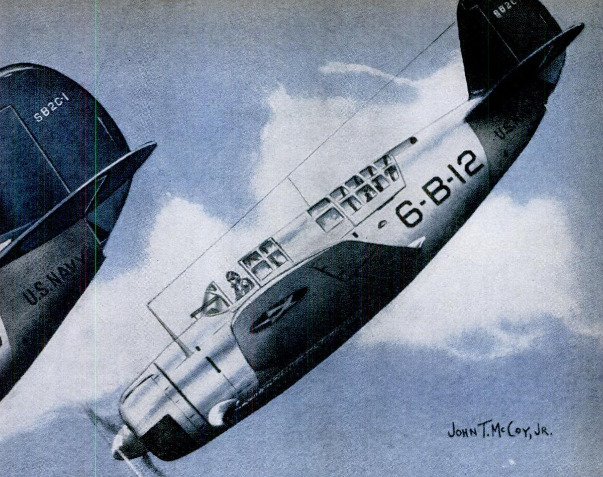

Other concerns currently producing their

own deadly versions of this single-engine

type of bomber include Vultee, Brewster,

and Curtiss.

The latter firm 1s best known for its

famous Allison-motored P-40 pursuit plane,

Which has been rolling off the assembly

lines at its Buffalo plant in quantity pro-

duction for months to bolster the alr de-

fenses of England and replace obsolete

oquipment of our own Army Alr Corps.

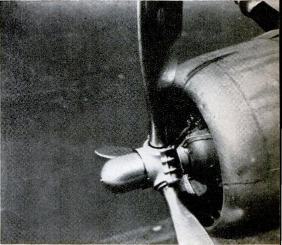

More recently, the Alr Corps has been re-

ceiving, also from Buffalo, the faster and

more formidable Bell P-30 Alracobra, a

tricycle-landing-gear pursuit ship in which

the “submerged” Allison engine is located

behind the pilot, driving the propeller

through an extension shaft extending along

the bottom of the cockpit to the plane’s

nose. In California, Lockheed has begun

production of its twin-engined (Allison)

P-38 pursuit after making thousands of

engineering changes

in the original de-

sign.

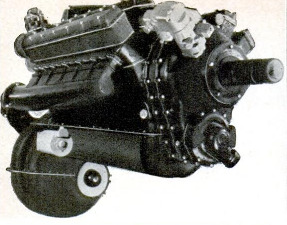

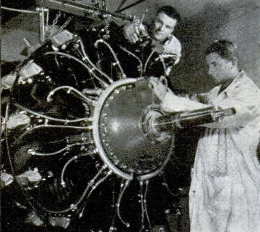

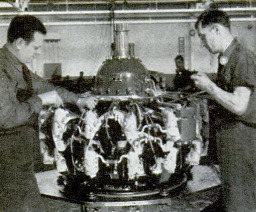

Both Pratt & Whit-

ney and Wright, the

principal aircraft-

engine suppliers of

America, have produced air-cooled radial

engines developing 2,000 horsepower or

more. It is no secret, and possibly signifi-

cant of future trends, that the Army is now

sponsoring several pursuit planes designed

around the radial power plants which had

been relegated to

bombers, cargo planes, and other secondary

military airplanes. The fact that the Navy

has stuck consistently for years to air-cooled

engines and brought out a Vought F-4-U

fighter last fall which it announced as “the

fastest airplane in the United States today,”

may have influenced the decision.

Although the twin-engined Lockheed P-38

pursuit has not yet been put in active

service, some Air Corps officers have felt

for a long time that the Army made a

fundamental mistake in its original design

by asking the designers to build a one-place

rather than a pilot and observer-gunner

airplane. They maintained that a twin-

engined ship was “too much airplane” for

one man to handle in a fight. Apparently

the twin-engined German Messerschmitt

110, with its accommodations for a crew

of two, and in some cases three men, has

borne them out. While the first production

orders of the Lockheed will be filled with

single-place planes, subsequent models will

Carry a crew of two.

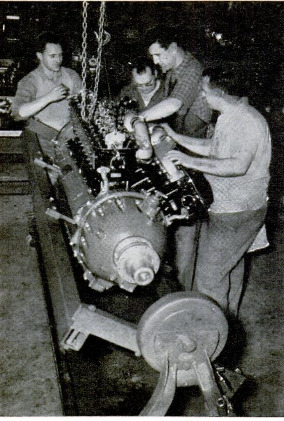

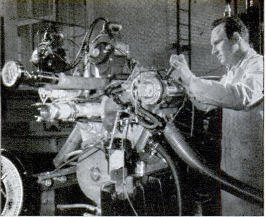

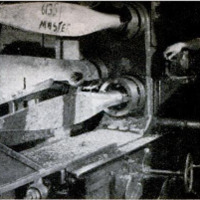

Reference has been made to the fact that

two manufacturers, Wright and Pratt &

Whitney, which for years have been the

country’s principal source of supply for

military-aircraft engines, have continued

to play this role in America’s frenzied aerial

rearmament program. They have accom-

plished this by one plant expansion after

another at or near their respective original

factories in Paterson, N. J., and East Hart-

ford, Conn,, and by judiciously guiding and

building up a system of engine parts sub-

contracting which has helped to spread their

burden among hundreds of manufacturing

plants in other industries and thus aug-

mented their own rate of production.

Furthermore, they have passed their

product along for manufacture under license

by automotive concerns—Pratt & Whitney

to Ford and more recently to Buick, which

is going to build its 1,200-horsepower, 14-

cylinder radial engine; Wright to the Stude-

baker Corporation, which will build its

1,700-horsepower twin-row Cyclone, and to

Continental, which already 13 building the

420-horsepower Wright “Whirlwind both

for training planes and for the Army's 28-

ton medium tanks. And even now, a big

new factory at Cincinnati, duplicating

Wright's Paterson set-up, is beginning to

turn out high-horsepower engines under the

company's own management, but with a

high percentage of parts produced by auto-

motive and other manufacturers.

-

Contributor (Dublin Core)

-

C. B. Allen (article writer)

-

Language (Dublin Core)

-

Eng

-

Date Issued (Dublin Core)

-

1941-08

-

pages (Bibliographic Ontology)

-

66-73,204

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

Popular Science Monthly, v. 139, n. 2, 1941

Popular Science Monthly, v. 139, n. 2, 1941

Screenshot_1.png

Screenshot_1.png Screenshot_2.png

Screenshot_2.png Screenshot_3.png

Screenshot_3.png Screenshot_4.png

Screenshot_4.png Screenshot_5.png

Screenshot_5.png Screenshot_6.png

Screenshot_6.png Screenshot_7.png

Screenshot_7.png Screenshot_8.png

Screenshot_8.png Screenshot_9.png

Screenshot_9.png Screenshot_10.png

Screenshot_10.png Screenshot_11.png

Screenshot_11.png Screenshot_12.png

Screenshot_12.png Screenshot_13.png

Screenshot_13.png Screenshot_14.png

Screenshot_14.png Screenshot_15.png

Screenshot_15.png Screenshot_16.png

Screenshot_16.png Screenshot_17.png

Screenshot_17.png Screenshot_18.png

Screenshot_18.png Screenshot_19.png

Screenshot_19.png Screenshot_20.png

Screenshot_20.png Screenshot_21.png

Screenshot_21.png Screenshot_22.png

Screenshot_22.png Screenshot_23.png

Screenshot_23.png Screenshot_24.png

Screenshot_24.png Screenshot_25.png

Screenshot_25.png