-

Title (Dublin Core)

-

Streamline motors for streamline planes

-

Article Title and/or Image Caption (Dublin Core)

-

Streamline motors for streamline planes

-

extracted text (Extract Text)

-

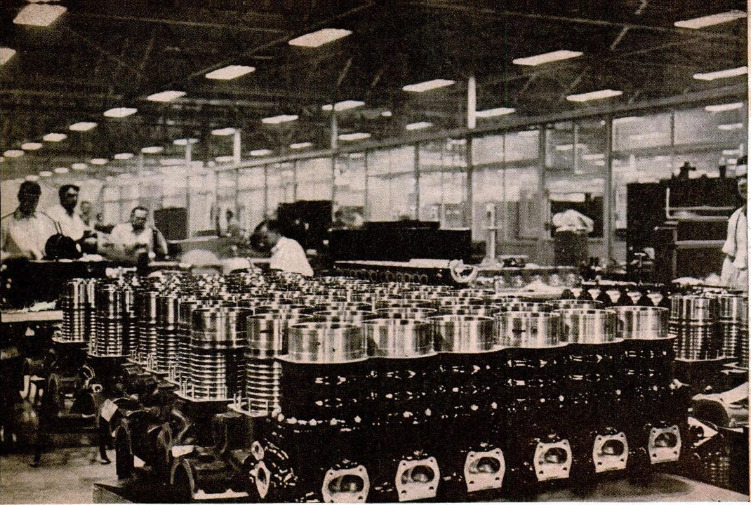

HERE and there in the United States,

like ganglia in a vast nervous sys-

tem, factories are working at top

speed in the production of power

plants. The world is fighting a war of mo-

tors. The explosions in engine cylinders

have become as important as the explosions

in cannons and machine guns. The quick

production of bigger and better engines for

planes and tanks is a front-page problem

of the day.

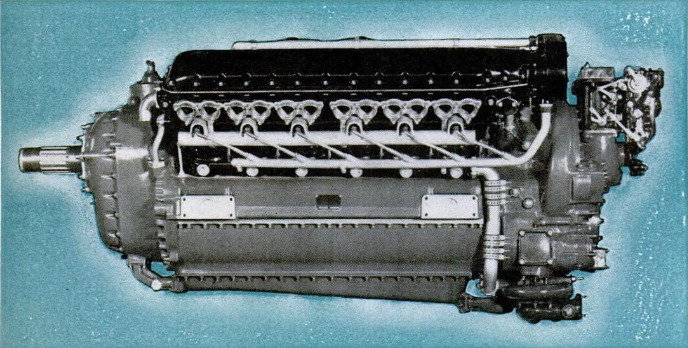

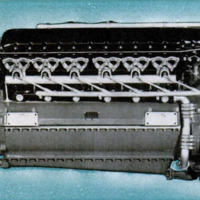

The more significant of these two engines

of war is the motor used to power pursuit

planes and bombers, the combatant and

striking arms of the air force. Because of

the great speed required in aerial tactics,

motors for warplanes are now generally of

1,000 horsepower or more. In this country

there are three manufacturers of such en-

gines that are now on a production basis.

Two—Pratt and Whitney, and Wright—are

established manufacturers of high-power

radial motors. By December, each will be

turning out 900 of these air-cooled power

plants a month. The third is the Allison Di-

vision of General Motors at Indianapolis,

which makes the Allison liquid-cooled mo-

tor, ranging from a twelve-cylinder job

rated at 1,090 take-off horsepower, to a

twenty-four-cylinder job, now in the ex-

perimental stage, tentatively rated at 2,300.

The company sometimes ships as many as

four or five engines a day, sometimes less.

This winter when its present production

plant will have been doubled, the manage-

ment expects it will be turning out 100 en-

gines a week, or 5,200 a year. The engine

has already been accepted as the power

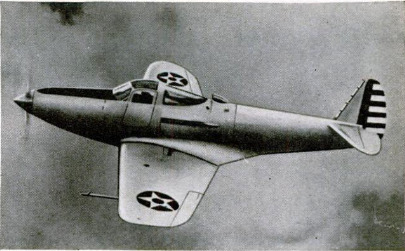

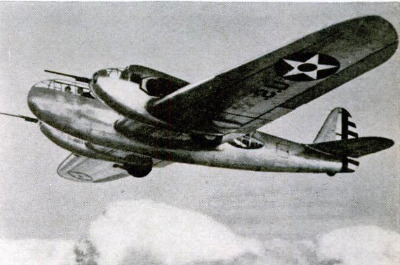

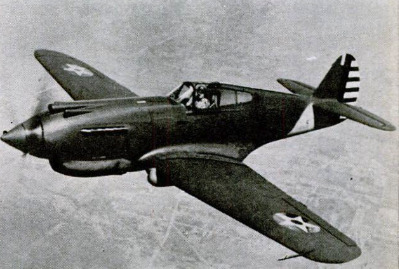

plant for the Curtiss P-40 and the Bell P-39

(Airacobra), both single-engine pursuits:

the Bell FM-1 (Airacuda), a

twin-engine multi-place fighter;

the Bell XFL-1 (Airabonita), a

Navy single-engine fighter; and

the Lockheed P-38, a twin-engine

interceptor. This acceptance was

based on a model test, applied by

the Government to motors made

in the experimental shop. The

Allison has yet to pass the pro-

duction-type test, which is ap-

plied to the engine made in quan-

tity in the factory.

If the production of Allison en-

gines meets the managers’ ex-

pectations, the country’s annual

rate of production of high-pow-

ered engines will be about 27,000.

This will be enough to power 18,-

000 planes, for one engine should

be held in reserve for every two

in service. However, since many

models will need either two or

four engines, the number of

planes will be about 12,000.

One of the reasons why ti

Government looks with hope :

the Allison engine is that higl

powered motors, up to now, hay

been put out by companies sp:

cializing in their manufactur

Allison, however, is an engir

controlled and sponsored by Ger

eral Motors, a fact that he

caused the governmental and poj

ular belief that the industry

now going to achieve mass pre

duction. This supposition hs

been based partly on the furth

fact that Allison, in a way, is

descendant of the Liberty engir

of World War I, a mass-produce

motor of 400 horsepower.

However, there is a great di

ference between the effort of 19]

and the effort of 1940. The Lil

erty engine failed as a militar

weapon abroad chiefly for tk

reason that the design engineer

had too short a time to do the jol

That they had the right idea we

proved by the performance of tk

Liberty after the War. The All

son engine will also be mass pre

duced, but under more favorab

conditions. There has been su

ficient development time, and o

ders for the engine have made

possible for General Motors to tool up. In-

deed, the preparation has been so thorough

that General Motors can actually build bet-

ter engines by mass-production tools tech-

nique than can ever be built by hand. The

finest handcraftsman cannot duplicate the

accuracy of American machine tools. The

problem is not so much in the application of

the methods of mass production as it is in

the adjustment of tools to operations upon

materials that hitherto have not been sub-

ject to such machining. This is a matter of

observation, adjustment, and practice in op-

eration. Actually there are many tolerances

in General Motors’ gasoline automotive en-

gines, and especially in its Diesel engines,

that are as fine as those in the Allison.

There are, however, more parts of the Al-

lison engine that require micrometric atten-

tion to limits than there are in the other

General Motors engines.

THE Liberty, which was also a V-type

liquid-cooled engine, was rebuilt after

the War in the very shops near the Indian-

apolis Speedway where Norman Gilman, an

ingenious Yankee mechanic who had

worked with Jim Allison on the old Lib-

erties, planned the first Allison. Convinced

that the engine of the future would be liquid

cooled, he discarded water as a cooling agent.

and designed an engine especially for the

use of a chemical cooler. This was in 1931,

two years after the Allison plant had been

bought by General Motors. On April 23, |

1937, the first Allison motor passed the 150-

hour test and the long struggle to get it

into mass production began.

The engineers who are bringing it into |

production give three major reasons for

their belief that it may prove superior to |

the air-cooled radial types to which most of

our productive capacity has been devoted.

Their reasons are: first, the air resistance,

or “drag,” is less than in the radial; second, |

the Allison can be divorced from the usual |

position directly behind the propeller; third,

it can maintain top speed for a longer time

than the air-cooled motor.

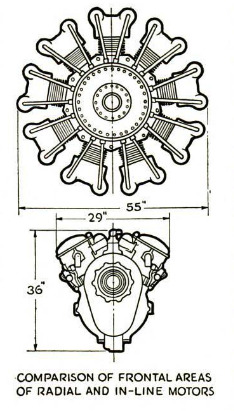

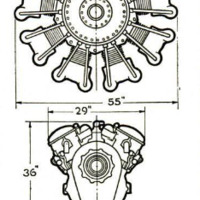

The claim of less drag is based chiefly on |

the difference in frontal areas; the twelve |

cylinder Allison has a frontal area of six

and a quarter square feet as against an area

of over sixteen square feet in the radial en-

gine of the same horsepower. The lower

area is a result of the V-shaped design, in

which the cylinders are in line, arranged

along a crankshaft, instead of protruding in

the sunburst arrangement of the air-cooled

radial. Drag increases as the square of the

speed: if the speed is doubled, the air re- |

sistance becomes four times as great.

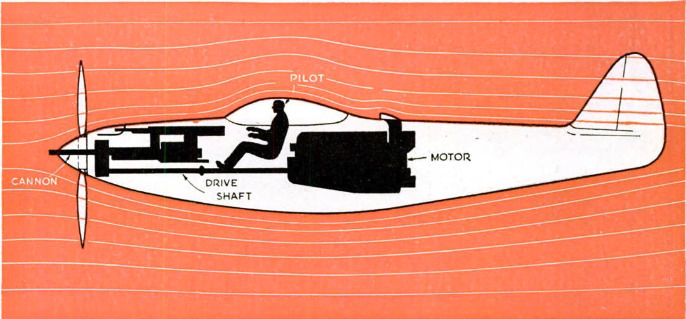

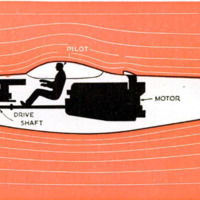

Distinctly more important is the fact that |

the Allison engine, being cooled by the flow

of liquid around its cylinders instead of by

a flow of air, need not be directly exposed to

the air. It can be completely hidden in the

wings or go back toward the tail. This |

freedom of the engine position gives the de-

signer a greater opportunity to design for

maneuverability, which modern war tech-

nology and tactics may prove to be more

important in combat than a few more miles

an hour. The Airacobra is a case in point.

Here the weights of the engine, the pilot,

‘and the fuel are clustered around the ship's

center of gravity. Here, again, fast han-

dling of the ship is helped by the better com-

bat and searching vision afforded by the

pilot's position over the leading edge of the

wing. Moreover, this plane requires a fuse-

lage only thirty-four inches

wide—less than six times the

width of this page—to take

the compact Allison.

The Allison engine can

maintain top speed longer be-

cause it is easier to cool. In-

stead of water, which was

used in the Liberty engine,

the cooler is ethylene gly-

col, the same chemical used

in nonevaporating automo-

bile antifreeze solutions.

Ethylene glycol is a by-prod-

uct of the synthetic produc-

tion of glycerin. Its boiling

point is 387 degrees, com-

pared with the 212 degrees of

water. The pump forces it

through the engine so swift-

ly that the heat dissipation

is uniform in all cylinders.

That's the Allison side of

it. There are engineers, es-

pecially among the makers of

air-cooled engines, who are

not certain that Allison is all that its back-

ers claim. Most of them accent the stream-

lining advantages, but they find them offset

by the problems of installation. But this is

a technical debating ground, where time and

research will settle the question.

The name “Allison” is a remembrancer of

Jim Allison, who, with Carl Fisher, founded

the Prest-O-Lite Co. and later established

the Indianapolis Speedway so that they

could play with racing cars. Allison put up

a machine shop to design and service the

cars and gathered a staff of engineers and

mechanics, whose superintendent, when the

U. 8. entered the World War, was Norman

Gilman, an old-fashioned Yankee mechanic.

‘When the war ended and surplus Liberty en

gines were being overhauled,

Allison obtained a contract to

do some of the work. It was

then that Gilman invented

the famous Allison bearing—

bronze integrated with steel

—which solved the problem

of getting more horsepower

out of the Liberties. When

Allison died and General Mot-

ors bought the plant (1929)

to secure for development the

bearings and a Diesel engine,

then being designed, Gilman

was made president and gen-

eral manager of the new divi-

sion. He built gears and pro-

peller drives for the Navy

dirigibles and many special

engines; and began his study

of the liquid-cooled type

through work on the German

engines on the Los Angeles,

our trophy of the World War.

The air-cooled engine had at-

tained about 400 horsepower.

but Gilman, like one or two other engineers,

became firmly convinced that the liquid-

cooled type of power plant was destined to

be the airplane engine of the future,

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1940-12

-

pages (Bibliographic Ontology)

-

62-65

-

Rights (Dublin Core)

-

Public domain

-

Archived by (Dublin Core)

-

Sami Akbiyik

-

Marco Bortolami (editor)

Popular Science Monthly, v. 137, n. 6, 1940

Popular Science Monthly, v. 137, n. 6, 1940