-

Titolo

-

Soldiers in overalls keep our war machine rolling

-

Article Title and/or Image Caption

-

Soldiers in overalls keep our war machine rolling

-

extracted text

-

AN ARMY officer who has what it takes

mae dead-tired men march all

night and attack in the morning, and

he can make scared-stiff ‘men fight and win

when the odds are all against them. That's

leadership—the most valuable quality that

an officer can have. But even ‘the best

leadership can't make a tank run “om &

broken track or get mileage out of a scout’

car with a cracked cylinder. It can’t grind

the valves of an ammunition truck, repair a

broken-down machine gun, or weld the

cracked axle of a howitzer. Those are jobs

for trained and skilled mechanics—for the

soldiers in overalls who keep the Army's

fighting machines running.

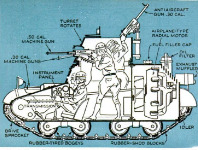

While our Army still is dangerously short

in the quantity of its mechanized weapons,

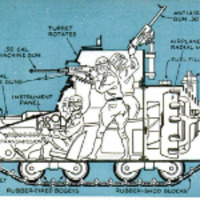

it is long on their quality. Our light tanks,

developed by the Ordnance Department, are

rated the world’s best. They have better

engines, better drives, better transmissions,

and better tracks than any other light

tanks; they are heavier, faster, and steadier

gun platforms. When it comes to the qual-

ity of their fighting vehicles, and their sys-

tem of keeping ’'em rolling, our mechan-

ized soldiers don’t have to take off their

snappy barrack caps to any army in the |

world. |

One of the purposes of the Third Army

maneuvers in western Louisiana this spring

was to give our Regular Army officers their |

first large-scale opportunity of practicing

the tactics and solving some of the problems |

of mechanized, motorized, and modernized

warfare. The maneuvers also provided a

stiff test of the Army's services of main-

tenance and supply. The mimic war |

meant two weeks of the hardest kind

of work for the 70,000 Regulars who

took part in it—especially for the

men who had the job of keeping roll-

ing the over 7,000 motor vehicles

which were driven hard both on the

roads and off them. There was plenty

of sweating done—but then, as

China’s General Chiang Kai-shek says,

“the more you sweat in peace, the less

you bleed in war.”

Following the light tanks of the

Mechanized Cavalry Brigade—then

the most thoroughly mechanized out-

fit in our Army—as they thundered

over the big maneuvers area on their

scouting and combat missions, I was

able to get a close-up of the operation

of the maintenance system of an or-

ganization which had 720 vehicles on

tracks and wheels—tanks, scout cars,

half tracks, trucks, passenger cars, and

motor cycles—and which regards attack-

ing at daybreak 150 or 200 miles away from

where hostile aviation reported it at dusk

as just another routine job.

Each troop has a maintenance section

which stays with it under all conditions to

make minor repairs both on the road and

on the battlefield. It is commanded by a

motor sergeant who is an expert trouble

shooter and travels in an armed scout car

followed by a truck which carries light re-

pair equipment, a small assortment of spare

parts, and an emergency

supply of gasoline and oil.

When a tank or scout car

is disabled it is pushed over

to the side of the road

and the rest of the troop

goes on forward to fight.

It is an unbreakable rule

that the officer in com-

mand must not wait for

cripples.

When the troop main-

tenance section comes up,

the motor sergeant checks

the disabled vehicle and

diagnoses the trouble. If

he has the time and

equipment for the job he

makes the repair, takes

the vehicle along with

him to the next halt, and

then sends it forward to

rejoin the troop. If he

can't make the repair, he

tags the job with his diag-

nosis, and leaves it. Its

crew always stays with a

disabled tank or scout car.

s0 that as soon as it has

been repaired ithev can

take it back into action where it belongs.

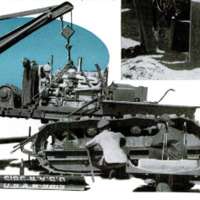

Following the regiment on the march is

the regimental maintenance section, which

carries witl. it a larger assortment of spare

parts and is equipped to handle jobs such

as changing tank tracks and installing new

shaft assemblies. When it comes up to a

disabled fighting vehicle the staff sergeant

who is its chief mechanic rechecks the job,

and if an immediate repair is practicable

leaves a crew to make it. If a roadside

repair can't be made, he has a wrecker

tow the cripple to where the regiment is

going to bivouac for the night, and the

repair is made there. When there is fight-

ing going on, a regimental service park

is established a few miles back of the

combat zone. Disabled vehicles are re-

ported to it by radio, and crews are sent

out to repair them on the battlefield or to

tow them in.

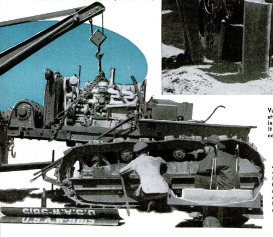

Jobs which are too big to be handled by

the regimental maintenance sections are

taken over by the brigade's ordnance main-

tenance company, which has machine-shop

trucks, welding apparatus, and other equip-

ment which, while sturdy, is light enough

to be carried in trucks. This organization

can handle almost any repair job, even

that of installing a new engine. It takes

with it into the field two complete engine

assemblies for each fifty tanks. Its 200-

odd highly-trained soldier-mechanics set up

their shop in a big square tent brightly

lighted by electricity supplied by a genera-

tor truck. Often they work all night to

make good on their boast that, if it is

humanly possible, they always have every

disabled vehicle ready to go when the

column pulls out in the morning.

There will be one of these maintenance

companies, probably increased in man-

power, in each of the two divisions of the

new Armored Corps now being organized.

Men now are being trained to do this

specialized mechanical work of the Army's

most modern fighting outfit at schools re-

cently established at Fort Benning, Ga., and

Fort Riley, Kans.

As important as keeping a mechanized

force's fighting vehicles in perfect mechan-

ical condition is the job of keeping them

supplied with fuel. There's

nothing in war more useless

or more helpless than a tank

with an empty gas tank.

Having a supply of fuel at

the right place at the right

moment always demands

careful planning and often

demands hard work. Tank

trucks have been tried and

discarded. Now cargo trucks

carry the fuel in ten-gallon

cans which, while the column

is halted, are dropped off at

each vehicle. This method

saves time, and time is the

determining factor in to-

day's warfare.

Attached to each of

the two army corps we

now have organized

there is a corps ordnance

battalion, and equipment

is being procured for

additional battalions so

that as the expanding

Army adds new corps

there will be a battalion

for each of them.

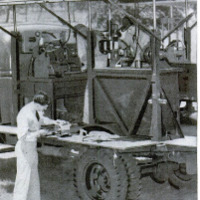

Each man in these bat-

talions is trained to ex-

pertness in some me-

chanical operation. After

he has mastered that

particular job he is

trained to handle other

jobs. All the equipment

is carried on trucks, and

most of it is used on

them, So the field shops

are ready for work a few minutes after the

trucks have scattered through some patch

of woods which will give them cover against

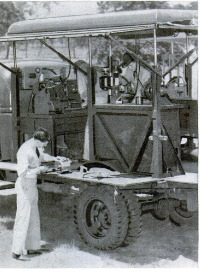

air attacks. Included in the equipment are

field welding outfits, machine-shop trucks,

and special firearms-repair trucks which

carry extensive assortments of spare parts

and the tools necessary for the repair of

machine guns, rifles, and pistols.

One of the jobs I watched being done dur-

ing the Louisiana maneuvers was the weld-

ing of the broken axle of a 155-millimeter

howitzer, without taking the big weapon

out of its firing position.

In its various post shops the Ordnance

Department has sturdy but comparatively

light machine-tool equipment capable of

doing all the work of a large job shop. In

war this would be taken into the field and

used by ordnance

maintenance battalions or regiments at-

tached to each field army.

The Motor Transport Service, a branch

of the Quartermaster Corps, is responsible

for the maintenance and repair of all the

Army's motor vehicles except tanks, scout

cars, and tractors used to haul artillery.

That's another big task. Even our small

“streamline” divisions include in their

equipment 1,357 trucks, trailers, passenger

cars, and motor cycles.

The job of the Motor Transport men is

to get spare parts and do repair work as

far forward toward the fighting line as is

possible—to keep vehicles working where

they are most needed and to keep them

from drifting back to the base for repairs.

There is a motor maintenance platoon in

the headquarters or service company of

each regiment. In the headquarters com-

pany of the quartermaster battalion of

each division there is a light maintenance

platoon, which probably soon will be in-

creased to a company, which supplies

parts and gives technical advice to the regi-

mental platoons, but does as little mechan-

ical work as possible. The divisional pla-

toons are supported by light maintenance

companies, which have truck shops equipped

to do jobs such as welding and cutting,

frame straightening, brake relining, bat-

tery charging, and valve grinding and seat-

ing. There also are maintenance com-

panies attached to each army corps, and in

war there would be a heavy maintenance

company, equipped for major repairs and

overhadle with cach field army.

Any soldiers or civilians who had doubts

about the deadly effectiveness of mecha-

nized war weapons lost them suddenly on

the day last spring when the 2,000 tanks the

Germans had massed near Sedan blasted a

wide and bloody lane through the French

defense lines and made it possible for the

German Army to win the stupendous battle

of France. That shattering, pulverizing at-

tack by Mars’ mechanical monsters brought

to terrible maturity the mechanized war-

fare which had been born on a misty morn-

ing in 1916 when the British sent their first

awkward and undependable tanks lurching

over the shell-pocked Somme battlefield.

To win in the intensified lightning war-

fare of today an army must have fighting

machines, and it must have soldier-mechan-

ics who have been trained to keep the ma-

chines running. There aren't any soldiers

who are more vitally necessary than the

soldiers who wear overalls.

-

Lingua

-

eng

-

Data di rilascio

-

1940-12

-

pagine

-

84-88, 232

-

Diritti

-

Public domain

-

Archived by

-

Sami Akbiyik

-

Marco Bortolami (editor)

Ekran Resmi 2022-02-02 18.10.53.png

Ekran Resmi 2022-02-02 18.10.53.png Ekran Resmi 2022-02-02 18.11.01.png

Ekran Resmi 2022-02-02 18.11.01.png Ekran Resmi 2022-02-02 18.11.07.png

Ekran Resmi 2022-02-02 18.11.07.png Ekran Resmi 2022-02-02 18.11.15.png

Ekran Resmi 2022-02-02 18.11.15.png Ekran Resmi 2022-02-02 18.11.20.png

Ekran Resmi 2022-02-02 18.11.20.png Ekran Resmi 2022-02-02 18.11.25.png

Ekran Resmi 2022-02-02 18.11.25.png Ekran Resmi 2022-02-02 18.11.29.png

Ekran Resmi 2022-02-02 18.11.29.png Ekran Resmi 2022-02-02 18.11.35.png

Ekran Resmi 2022-02-02 18.11.35.png Ekran Resmi 2022-02-02 18.11.41.png

Ekran Resmi 2022-02-02 18.11.41.png