-

Titolo

-

Saving a ship

-

Article Title and/or Image Caption

-

Title: Saving a ship for Uncle Sam

-

Subtitle: Salvage engineers are using all their tricks to give us back the Mammoth Normandie

-

extracted text

-

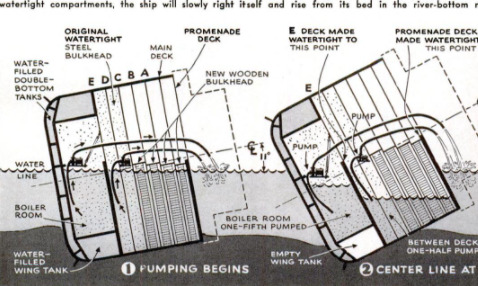

CONFRONTED by the biggest ship-salvage

job in marine history, the experts as-

signed to raise the former French liner Nor-

mandie from the mud of New York's North

River had to start literally at the bottom by

setting up their own school for divers. Under

war conditions, the 100 or more underwater

workers needed for the job simply could not be

found. Right at the pier where the mammoth

luxury ship (now the U.S.S. Lafayette) lay

on her side, Navy enlisted artificers were in-

structed in the rudiments of diving and under-

water salvage. At the same time, young naval

officers graduating in engineering were rushed

through a special course in naval architecture

to sorve as junior foremen on the big job.

To complicate the task, the only complete

set of blueprints of the mammoth ship had

been aboard when she burned and sank.

Those that could be recovered were drawn

up in the metric scale used by French de-

signers. For weeks the engineers had to

mark time while more than 500 workmen

explored the 1,029-foot vessel inch by inch,

the divers working by touch since the silt in

the water was so thick that even powerful

underwater lamps could not pierce it.

It soon became clear that salvaging prob-

lems never before raised had to be solved.

For one thing, the after portion of the

ship was bedded in soft mud whose maxi-

mum bearing capacity in some places was

less than the pressure exerted by the heeled-

over vessel. In addition, the layer of bed-

rock at the bottom of the slip rises toward

the shoreline at a uniform grade until it

reaches a level of 46 feet below low water at

a point about 250 feet aft of the bow, then

continues to the bulkhead line at the head

of the slip with a uniform level of minus

46 feet. The top of the mud line in the slip

occurs at about minus 36 feet, but samples

taken from this level down to minus 43 feet

showed the mud to be of very liquid con-

sistency. Although the greater portion of

the ship's weight was resting in mud, there

was found to be a considerable concentra-

tion of load at the edge of the rock shelf.

Engineers soon discovered that the ship's

original position was unstable. Transit rec-

ords taken at regular intervals indicated

that the stern was constantly settling

deeper in the mud, while the bow showed a

corresponding rise. The fulcrum of the mo-

tion was at the edge of the rock shelf.

There are at least 20 different ways of

salvaging a ship. The engineers working on

the Lafayette had to choose between them,

bearing in mind the special conditions pre-

vailing at Pier 88. Obviously, they could do

nothing that would disturb the mud in the

slip, since the ship's position was already so

precarious. The immediate job was to

lighten the stern or restore some lost buoy-

ancy quickly to the middle portion, as well

as to re-establish enough buoyancy to elimi-

nate the concentrated loading at the edge

of the rock shelf. After weighing the pros

and cons, the engineers finally cast their

votes for the method of controlled pump-

ing, whereby watertight compartments are

erected within the ship and then carefully

emptied in predetermined sequence so that

the list and trim of the vessel as it is floated

and righted will be subject to control.

This method, while quicker and more cer-

tain of success than any other, involves a

vast number of preliminary operations,

most of them under water. The vessel's list

and trim as it comes afloat will not be con-

trollable unless the movement of the free

water remaining in the ship is restricted by

both fore-and-aft and transverse bulkheads.

Before pumping can begin, all the compart-

ments which are to be emptied must be

sealed tight and drain holes must be in-

stalled to eliminate fatal water pockets.

However, before any constructive div-

ing operations inside the ship could get

under way, underwater compartments

had to be cleared of the mud and debris

with which they were clogged. When

the vessel toppled over, about 10,000

cubic yards of mud entered the hull

through open or broken air ports, cargo

ports, and deck hatches. To further com-

plicate matters, all the loose furniture,

ornamental fittings, and other equipment

had dropped to port and mixed with the

mud in the ship's lower portion. All this,

plus huge quantities of broken glass—

the diver’s deadly enemy, since it can cut

his air hose or rip his diving dress—had

to be cleaned out.

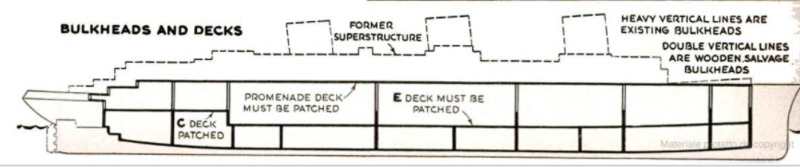

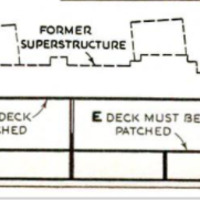

Today a great deal of this preliminary

work has been accomplished. Many par-

tition bulkheads, ornamental sheathings,

and deck insulations have already been

cut away wherever they interfere with

diving operations. And over 95 percent

of the ship's superstructure—practically

every item above the promenade deck,

including the three great smokestacks—

has been stripped away and scrapped,

yielding almost 4,000 tons of precious

metal. The removal of these top decks

has lowered the ship's center of gravity

and decreased the magnitude of move-

ment needed to right it.

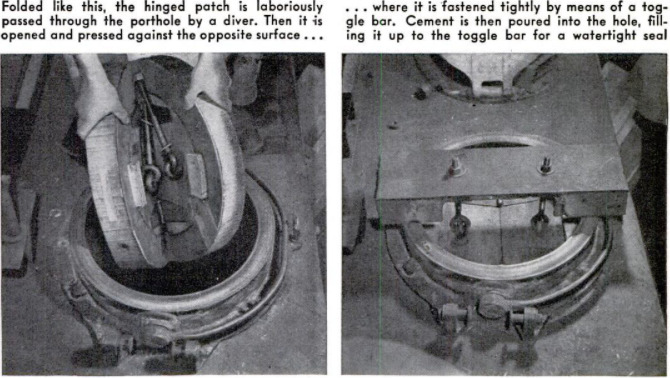

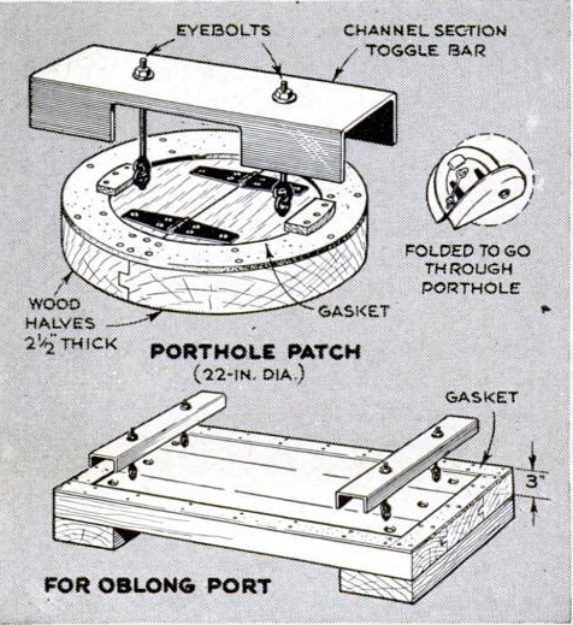

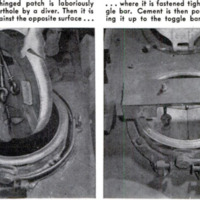

Now most of the divers are hard at

work on the main job, that of sealing up

the compartments to be used in con-

trolled pumping. The underwater por-

tion of the promenade deck is being

reinforced from the main deck by shores,

to enable it to withstand external water

pressure when the pumping begins. All

of its submerged openings—elevator

hatches, air ducts, engine and boiler

hatches, as well as countless smaller

vents of all sizes and shapes—are being

sealed tight from the port side to a point

well above the high-tide level, so that

the deck will be serviceable as one of

the fore-and-aft bulkheads.

The other deck being used as a fore-

and-aft bulkhead is E deck, which in the

original design was more nearly watertight

than the others, since it was at the water

line and sealed in sections as a precaution-

ary measure. With the complete sealing of

the port sections of the promenade and B

decks, the ship will be divided longitudi-

nally into two compartments running from

bow to stern. These long chambers will, in

turn, be broken up by a series of transverse

bulkheads.

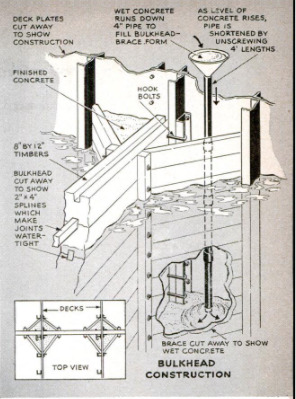

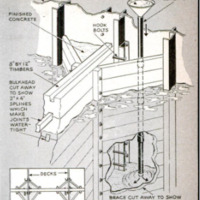

Practically all the Lafayette’ original

transverse bulkheads, except for a few near

the ends of the ship, were built up as far

as E or D deck, that is, just up to, or one

deck above, the water line when the ship

was afloat. But now, since the ship is over

on its port side at a 79-degree slant, the

original transverse bulkheads have to be

extended right straight through to the

promenade deck, then reinforced and built

up above the present low-water level, which

on the port side is almost halfway up the

110-foot-wide promenade deck. When this

huge job is finished there will be eight

transverse bulkheads extending clear out

to the promenade deck, spanning the entire

nine-deck depth of the ship, and four more

going up as far as E deck.

Building these bulkheads is the biggest

construction item, but another engineering

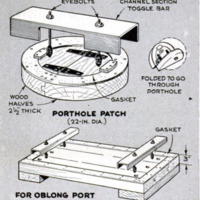

headache comes from the thousand-odd

vents found In all locations on the ship.

In addition to the approximately 375 air

ports, 14 cargo ports, and miscellaneous

scupper and drain pipe openings and

hatches now under water on the port side,

there are about 500 various openings in the

port side of the promenade deck alone

which must be blanked off.

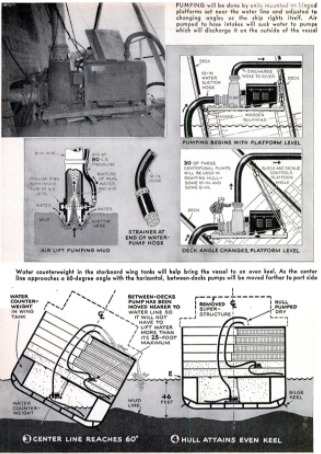

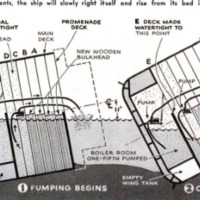

When all the preliminary stripping and

bulkhead construction is finished, pumps will

be installed and the raising of the vessel will

begin. With a system of suction and dis-

charge pumping, controlled quantities of

water will be removed from the numerous

watertight chambers, starting down near

the bow to increase the buoyancy at that

point. until the ship floats clear from the

rock ledge on which it now rests. At the

same time, or immediately following, the

buoyancy aft and amidships will have to be

increased to prevent the rest of the ship

from nosing deeper into the mud.

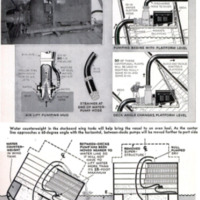

Once the ship is completely afloat, the

pumping will be altered to cause a listing

‘movement that will bring it upright again.

During all these complicated pumping oper-

ations, the wing and double-bottom tanks

which line the ship's keel will be used as

supplementary controls, as well as all the

chambers built up by bulkheading and

sealing off the decks.

When the prostrate Lafayette is floated

and righted again, only half the battle, al-

though the toughest half by far, will have

been won. It will take many more months

before she is reconditioned and fitted out

for whatever war duties are assigned to her.

But in the meantime, invaluable experience

in salvage is being gained by the hard-

working experts who swarm over the ves-

sel's barren, rusted hull and feel their

way through its muddy depths. This experi-

ence will augment the number of trained

salvage personnel in the service—a valu-

able addition to our fighting services.

-

Autore secondario

-

Bernard Wolfe (Article Writer)

-

Lingua

-

eng

-

Data di rilascio

-

1943-02

-

pagine

-

108-113

-

Diritti

-

Public Domain (Google Digitized)

-

Archived by

-

Matteo Ridolfi

-

Marco Bortolami (editor)