-

Title (Dublin Core)

-

Chemists on the front

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Chemists fight on 1000 fronts

-

extracted text (Extract Text)

-

LIKE you and me and 130,000,000 others,

the American chemist is in this war

to win. But unlike most of us, he's fight-

ing it on a thousand fronts at once. He

sees that Marines pushing forward in the

South Pacific have more punch in their

ammunition, that our planes have the extra

snap and drive of high-octane gasoline,

that there is TNT in those 8,000-pound

bombs that drop on German war plants. At

the same time it’s his job to see that Tom

Jones, defense worker, doesn’t get sick

from exposure because he can't get a wool

overcoat, a rubberized raincoat, or medi-

cines. And that Mrs. Jones’ table has va-

riety even though tin is needed for war

industry and can’t be spared for cans.

This war is being fought by billions of

people using hundreds of thousands of

things. It's being fought with everything

from high explosives and heavy metals to

that tiny bit of plastic that goes into the

tips of your shoelaces in order to save

that much more metal for ships and tanks.

Thousands of those things are born in

the test tube or under the microscope. The

chemist has been drafted for the duration.

His job is as vast as global war: new, bet-

ter, quicker ways of making the old things

... new things to take the place of the old

where shortages threaten war production

or civilian comfort.

For chemistry at war doesn’t mean just

poison gases like chlorine, phosgene, or

lewisite. It doesn't mean ‘secret weapons.”

It means new landing fields for fighting

planes created overnight. Chemistry does

that. Barrels of dilute sodium silicate

poured over raw meadowland toughens the

ground and saves weeks of digging, of haul-

ing crushed stone for a foundation. Then

a layer of new, quick-setting, tougher as-

phalt, and your war birds can hit the tar-

mac at 150 miles an hour with no fear

of a crack-up.

It means tanks, trucks, and jeeps rolling

forward under cover of a smoke screen

made with chlorsulphonic acid. And the

chemist had to find something to take the

place of the chlorine that whitened your

linen or bleached the pulp for your morning

newspaper, to scrape together all the chlor-

ine needed at the front.

The foot soldier behind those tanks owes

a big debt to the chemist. The lining of his

combat helmet is not metal. The stock of

his Tommy gun is not wood. Both are

phenol formaldehyde plastics compounded

out of the same chemicals.

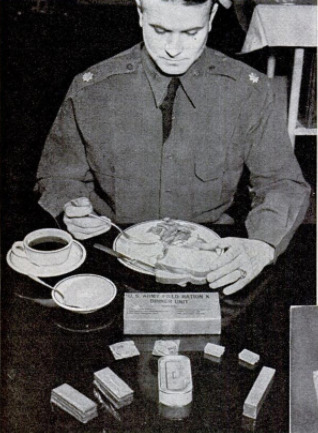

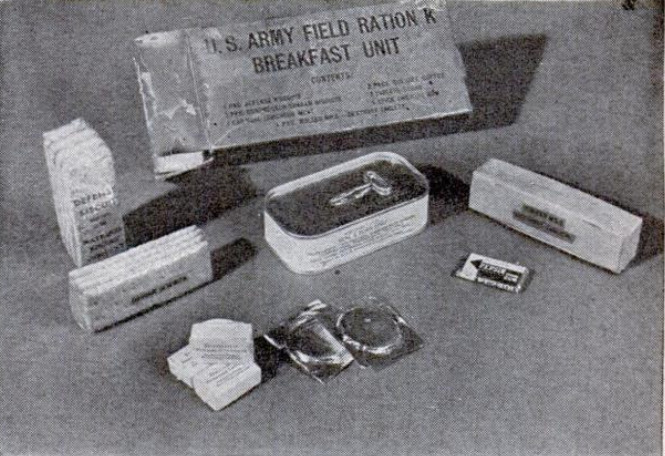

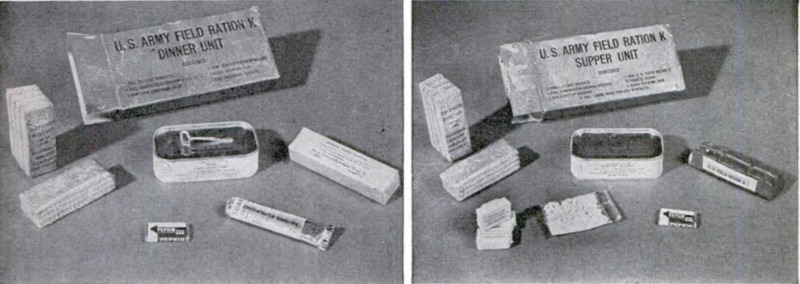

He may smash through enemy lines. The

advance may carry him two or three days’

march ahead of his field kitchens. But in

his pack your doughboy carries several ob-

long packets of Ration K. Each contains

the equivalent of three full meals—a day's

rations, in a container the size of a sample

box of breakfast food!

Special goggles protect his eyes against

the glare of desert sands or arctic snows.

And if the lenses -should become scratched

or dented, he merely throws them away and

slips in another pair. Molded out of a light-

polarizing, nonshatterable vinyl polymer,

they are produced in a fraction of the time

and at a fraction of the cost of grinding

glass lenses. Best of all, eyeglasses are no

longer a danger to the soldier in battle.

Chemistry found the answer to that prob- |

lem and to many others—Ilike the danger

of death from fire in a plane set ablaze by

enemy incendiary bullets. Today your

fighter pilot's flying suit may char, but it

will not burn. It has been made flameproof

with tricesyl phosphate or with ammonium

sulphamate, |

In field and base hospital, chemistry plays

a major part. Army medical men are be-

ginning now to talk about our “victory” at

Pearl Harbor—the victory of sulfanilamide

and sulfathiazole, made in the U.S.A. But

the chemist has already passed beyond the

miracle of the sulfa drugs. Synthetic urea,

long used in making plastics, fertilizers, and

beverage alcohol, is expected to save thou-

sands of lives through a new technique for

the treatment of wounds. |

Malaria is an enemy more deadly than the

combined Axis armies. Each year it kills

more victims than died on both sides in the |

last World War. Without quinine, or some

other weapon against malaria, our soldiers

could not hold out for a month in the South

Pacific, Africa, or India. Our major sources

of quinine are in Japanese hands today.

Yet, less than a year after Pearl Harbor,

three new American-made drugs, plasmo-

quin, atebrin, and totaquine, are competing

for the honor of filling quinine’s shoes. The

first two are synthetic quinines. The third

is made, like quinine, from cinchona bark. |

South America cannot supply us with

enough cinchona bark to give us the quinine

we need. But it can ship us enough to make

a little quinine, plus plenty of totaquine. |

That's good news not only for our fighting

men in tropical countries, but for something

like 1,000,000 civilians in the United States

who have malaria today.

These jobs sound important enough, and

thousands of them add up to big figures on

the score card of total war. But there are

far bigger jobs.

Let’s look at the new heavy artillery of

American chemistry at war. These big guns

are the latest fractional distillation towers

and cracking plants for breaking down

crude oil into many vital war materials.

More impressive than the biggest blast fur-

naces of the steel age, the huge batteries of

sleek, cylindrical columns are like cannon

aimed to shoot half way round the world—

which is just what they are doing.

‘Within two years, they will be turning

out enough butadiene to give us more than

1,000,000 tons of synthetic rubber. From

those towers, instead of the plantations of

Malaya, will come the tires for our trucks,

tanks, planes, pontons, self-sealing gaso-

line tanks, and gas masks—as well as for

our own aging cars.

From those same heavy batteries will pour

motor fuel—100-octane and far higher if

our engineers can design motors to make

full use of such gasoline—light oil; benzene;

acetylene for plastics, rubber, and synthetic

textiles; and toluene.

Suppose a chemist had walked into the

G.H.Q. of the Allied High Command in 1917

and said: “Gentlemen, give me

plenty of petroleum—just plain crude

oil—and money to build plants, and

I'll guarantee you as much TNT as

you can use!” What would have hap-

pened? The august generals would

have shipped him off to an asylum.

Trinitrotoluene — innocent-looking

pale, yellow crystals made up of car-

bon, hydrogen, oxygen, and nitrogen

—is the demon destroyer of modern

war. TNT is made from toluene and

nitric acid. Step it up with more

nitrogen in the form of ammonium

nitrate and you have amatol, another

deadly explosive.

In World War I the Allies had to

depend for nitrogen compounds on

natural nitrates, chiefly Chile salt-

peter. These had to be mined, lugged

hundreds of miles to the seacoast, loaded

onto ships, Those ships—thousands of them

—threaded their way painfully across the

world's oceans at six or eight knots. Then,

unless they were sent to the bottom by Ger-

man subs the nitrates were unloaded,

shipped again, refined, treated with sul:

phurlc acid, and finally made into nitric

acid for explosives.

Toluene, the other partner in the combi

‘nation, has a romantic history. Discovered

by a French chemist just 100 years ago in

the balsam of the folu, tree that grow in

South America, it was later obtained from

the balsam of an static palm, called "Drag-

on's Blood.” Ita chief use then was to give

a pleasant taste to cough sirups. But before

it found its way into the manufacture of

high explosives, toluene was being recovered

trom coal tar.

At that particular job, the Allies were

hopelessly outclassed. The chemists of Ger-

many were years ahead in breaking down

that black, sticky mass called coal tar, a

by-product of the coke ovens that furnished

fuel to her enormous steel Industry. From

i, the Germans had bullt up a long list of

synthetic dyes and drugs, and they were

ready to turn their skill to more deadly

work.

‘But the American dye industry was in its

infancy 25 years ago. It could turn out no

more than a fraction of the toluene needed

by the Allies.

"Yet since Pearl Harbor the rash promise

of “all the TNT you can use” has been made

by American chemists. And it wil be kept.

For American petroleum chemists have

learned to make toluene from crude ofl far

faster than it can bo synthesized from coal

tar. When our plants are finished, toluene

‘will pour out in quantities to match our new

‘production of nitrogen, which wil literally

be snatched out of the alr through the high-

pressure synthesis of ammonia!

High-octane gasoline ia really the grand-

father of the TNT bombs that drop on Ger-

many today—a grandfather only five years

old! It was while seeking means of making

more high-octane fuel that petroleum

chemists discovered they could break crude

oil down and reshape it into a host of other

things. In working for more and better

high-octane, they learned to make hydro-

carbon, ethyl and methyl alcohol, and other

carbon‘ hydrogen-oxygen compounds that

are tho bricks and stones from which are

bullt lacquers, paints, varnishes, and sol-

vents; rayons and plastics; dyestuffs, tex-

tile and leather olla; synthetic rubber; medi-

cines, chloroform, ‘poisons, toiletries, tear

gas, poison gas, vitamins, soupless soaps, a.

spray to ripen frreen frult after it has been

plcked—and toluene! They discovered that

it 1s possible to make from crude oil many

things that can be obtained from coal tar.

Not only in big things are our battles

being fought and won in American labora-

tories. Some of the lesser skirmishes are

nearly as Important and just as Interesting.

arly in the defense program the Army's

ordnance men realized that a shortage of

brass would hold up the manufacture of

cartridge cases. Unlimited TNT would win

Bo wars unless we had the cartridges. To

make the cases out of thin-gauge steel was

easy. Copper plating would take care of

the outside. But the inside must withstand

nitrocellulose, nitroglycerin, acetic acid, am-

‘monium hydroxide, ethyl alcohol, and ethyl

other. If it in coated, the coating must re-

sist extremes of heat and cold. It is worth-

leas if it scratches or chips off when the

shell is loaded. The chemists of Frankford

Arsenal found the answer In a straight,

water-clear, phenol formaldehyde baked-on

finish. Yes, you skeet shooters and rifle

fans, the day of dependence on expensive

brass for cartridges is past.

Armies that have to fight in all kinds of

climates use staggering quantities of wool.

It would take nearly the entire wool clip of

the United States for two years to outfit

every soldier in our Army, not counting

civilians or the troops of our allies! Yet

the spoilage of woolen goods is tremendous,

as every housewife knows. One female

moth and her descendants can, in a single

year, destroy as much wool as 13 sheep can

produce! Soap alkalis ruin wool, while cer-

tain enzymes decompose it and some bac-

teria seem to thrive on it.

IN ITS molecular structure, wool differs

from all other fibers. Long chains of mole-

cules are joined together by other, weaker

chains, sprouting in all three dimensions.

It Is these weak cross links which are bro-

ken down by the moths digestive juices or

the soap alkalis, so that the tougher chain

Sbers fal apart,

Chemists of the Bureau of Standards

have an answer to the problem. They do

the moths work for her. They dissolve the

weak disulphide or cystine bonds of the

wool with soluble organic sulphur com-

pounds known as mercaptans. Then they

replace the severed bonds with a chemically

stable material through the use of a re-

agent like methyl or ethyl dibromide. The

chemical reagent builds new cross links that

are proof against moths, alkalis, or bacteria.

And 50 you have wool that is mothproof and

can safely be washed with ordinary soap!

Jot this down in your notebook for V-day.

The woolen suit you buy after the war may

De a trifle more expensive, but it will outlast

the old one four to one. And no expensive

dry cleaning. Tl go right to the laundry

with your socks.

I¢ you stand on the sidelines, it looks as

though American chemists sprang suddenly

to life on December 7, and have been fran-

tically pulling rabbits out of hats with both

hands ever since. It is true that they have

crammed into a few months progress that

would normally have taken years. But look-

ing at that, and that alone, does not give a

fair picture.

When guns stopped talking in 1919, our

chemists began thelr conquests whers our

Soldiers had left theirs. They took from

Germany her leadership in the synthetic-

dye industry. They gave us improvements

in stainless steel and & host of other im-

provements in heavy and light metals. Re-

search on silicates let the sunlight into our

skyscrapers through walls of glass brick;

developments in refrigerants and insulators.

gave us alr conditioning and quick-freeze

food storage, and freed us from lifelong

servitude to the whims of climate.

We got a whole world of new plastics

out of coal, air, and water; synthetic rub-

ber; aluminum ‘in our planes, automobiles,

railway cars and kitchen stoves; practically

indestructible finish on our cars; high-oc-

tane gasoline, neon lighting, nylon stock-

ings, rayon underwear, vitamins that

streamlined our eating, and sulfa drugs

that revolutionized medicine.

Our chemists were producing for peace,

not war. But they were training men, per-

fecting techniques, building a vast machine

that needed only a signal to slip into high

gear for war production if necessary. The

petroleum industry alone had built up an

army of 6,00 research workers.

That's why, by the end of next year, we'll

be producing seven times as much alumi-

num as we made in 1939—enough to build,

in one year, three times the number of

passenger cars on all American railroads.

That's why, with new plants designed to

produce magnesium from sea water, we can

afford to put half a ton of that light metal

into every fighting plane we build. That's

why attack gliders and training planes of

wood are rolling off the production lines

right now. With years of experience with

synthetic resins, chemists were able to pro-

duce phenol formaldehyde binders and fin-

ishee to cement layers of wood veneer into

a material tougher in proportion to its

weight than anything engineers had ever

worked with.

NOT alone has the chemist pulled the |

throttle wide open in his own industry.

He has stepped into nearly every other in-

dustry with aids to faster and more efficient

production. The dry-cleaning fluids that

used to clean your best suit are going to

war plants now instead. Theyre used to |

clean metal surfaces—speeding up plating,

lacquering, and painting of those surfaces, |

With new solvents and a continuous-belt |

device, chemical engineers have reduced the

time needed to bleach cloth for uniforms |

from 12 hours to two. And now comes the |

explosive rivet—one of the most fascinating |

little gadgets ever conceived by the mind |

of man—putting an end to one of the most

serious bottlenecks of plane production with

a bang!

Of 250,000 rivets in a Flying Fortress, as

many as 10,000 may be in awkward places

that can be reached from only one side.

Today these are fastened with a rivet that

has a small charge of explosive in its shank.

When the rivet is in place, the charge is set |

off by heat from an electric gun. Nothing |

crude about that operation! Chemistry con-

trols the force of that tiny explosion to

within 1/20,000 of an inch! The chemist

even plays his part in easing the vital war-

time shipping problem. Through working

out ways of dehydrating foods without de-

stroying flavor or value, he makes one ship

do the work of four in carrying foodstuffs

to our allies.

When peace comes, the chemist will slip

back into civilian clothes as easily as he

slipped into uniform on December 7. Even

now he’s doing things for civilians every

day.

Don't let anyone tell you that, because we

can no longer get Asiatic pyrethrum for in-

secticides, you'll be eaten alive by mosqui-

toes and gnats when warm weather rolls

around again. Chemists have discovered a

more deadly insect Killer in the thiocy-

anoacetate of a secondary terpene alcohol,

which comes from the pine trees of our

own South. And if that should fail to im-

press your particular brand of houseflies

or other pests, they've found a homegrown

source of rotenone in a weed that grows in

Texas.

Though you can't get copper screening

for your windows any more, your chemist

will ‘see you through. He's perfected win-

dow screens without wire—woven of plastic

—and your hardware man will probably

have them by next summer. If military

needs should call for all the leather we can

produce, shoes without leather are ready

to fill in the gap.

You can’t get chamois skin any more, so

how are you going to keep the windows

clean? Well, your chemist has found the

answer even to that. After just two hours

in a new tanning solution of chromic sul-

phate, sulphuric acid, and sodium silicate,

the skin of a plain American sheep turns

out to be the best chamois cloth you ever

saw!

Does the front porch need painting? Well,

by next year your paint worries should be

over. There are new pigments to take the

place of the zinc needed in war industry;

new synthetic resins to double for the nat-

ural resins we used to get from Zanzibar,

the Congo, and Borneo. And new vegeta:

ble oils.

Our paint industry was hard hit when Jap

armies swarmed down on the Burma Road,

cutting off our biggest source of imported

tung oil. War had already dried up the

stream of other imported oils needed for

the making of paints. But now a chemist

has come forward with news that ought to

make headlines but will not, because we've

grown to take miracles for granted. Start-

ing with our homegrown corn, soybean, or

linseed oils, chemists can give us new oils

tailor-made to fit any requirements.

The postwar world will be one of abun-

dance. The word “scarcity” will have lost

its meaning. There will be enough fertilizer

nitrogen to turn every farm into the equiv-

alent of a tropical garden. Out of new ma-

terials already developed we shall build

homes lighter, airier, better insulated and

temperature-controlled, at a fraction of the

cost and effort that home-building used to

involve. The whole

process of produc-

ing, storing and ship-

ping the things we

eat, wear, and use

will be vastly

changed for the bet-

ter.

Any preview of

that world would be

fanciful and distort-

ed. But you can see

its beginnings if you

watch what chem-

ists are accomplish-

ing in a score of

fields that are going

to bring a revolution

in our ways of living.

-

Contributor (Dublin Core)

-

Alfred H. Sinks (Article Writer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-02

-

pages (Bibliographic Ontology)

-

58-63

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

Popular Science Monthly, v. 142, n. 2, 1943

Popular Science Monthly, v. 142, n. 2, 1943