-

Title (Dublin Core)

-

The typical American flyers

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Anthropology shows you the typical American flyers

-

extracted text (Extract Text)

-

SHORTLY after America entered the war it was

discovered, in the testing of an experimental

bombing plane, that while a flyer of average size

could easily squeeze through the escape hatch to

bail out of the ship, a big flyer could not possibly

make a jump without first taking off his parachute.

The hatch had been made too small.

This embarrassing “bug” was immediately cor-

rected by the manufacturer, but meanwhile it had |

performed an immensely useful service. It had em- |

phasized and dramatized an important fact which

was beginning to be realized at the Aero-Medical

Research Laboratory at Wright Field: designers of

flying equipment did not have enough precise knowl-

edge of the shape and size of the young men who

were going to use it.

To avoid trespassing on the flyers’ physi-

cal limitations, as designers strained to

make the best use of every ounce and inch

of an airplane, it became more and more

important to have such knowledge.

In one special fleld it was immediately

and urgently needed—the design of oxygen

masks for high-altitude flying. This kind

of flying has been made possible by m-

provement in oxygen equipment no less

than by development of engines and planes;

but the masks in use are still far from per-

fect, even though the late models are

guarded as prime military secrets. One

great problem is to design a mask, prefer-

ably not of rubber, which can be turned out

by mass production in as few sizes as pos-

sible and will operate with a minimum of

leakage on the great variety of faces to be

found on the thousands of fiyers in the

Air Forces,

When Thunderbolt meets Messerschmitt

at 30,000 feet, a mere one-percent advan-

tage in mask efficiency may well mean the

difference between victory and death. And

mask efficiency is a matter of anatomy.

Col. Otis O. Benson, Jr. chief of the

Aero-Medical Laboratory, consulted Prof.

Earnest A. Hooton, the noted physical an-

thropologist of Harvard University, and

together they worked out a program of re-

search aimed to classify the physical char-

acteristics of the American flyer. Hooton

picked out four of his star students, ex-

perts at using slide calipers, spreading

calipers, anthropometers, and other pre-

cisely scaled instruments for measuring the

topography of the human body. Last Feb-

ruary they set to work in two teams at Air

Force replacement centers, making detailed

studies of the heads, limbs, and bodies of the

young men entering the Air Forces.

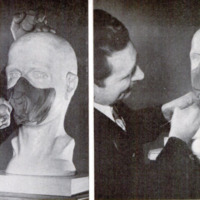

Today the first tangible results of that

study are embodied in seven sculptured

heads, representing precisely measured

composites of all the types of faces found

among 1,871 young men. Graduated from

long to short, the seven heads present a

graphic demonstration of the broad range

required in a satisfactory form-fitting oxy-

gen mask.

Since autumn, plaster replicas of these

seven heads have been in service in the de-

signing rooms of all manufacturers of

oxygen equipment, serving as embodied

specifications. Varied as the faces may

seem, they actually represent a simplifica~

tion of the problem, for in relation to the

physiognomy of the people as a whole,

flyers run pretty much to type. Earlier

advances in mask design were made almost

entirely by medical doctors who, lacking

any large group of aviators as models, tried

out their devices on the faces of hospital

patients. Obviously the air force cadets,

selected for youth and physical fitness, will

have a different range of facial contours

from any collection of invalids.

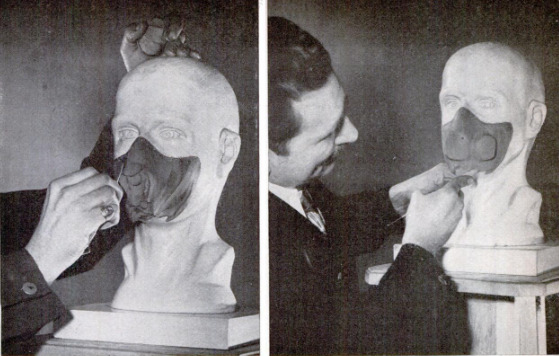

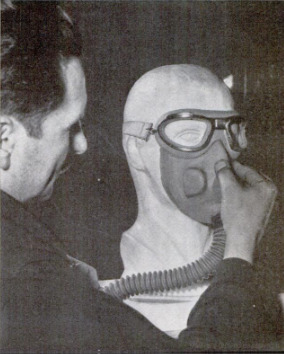

Engineers working on mask design are

able to mold their experimental masks di-

rectly on the faces of the plaster casts,

knowing that with certain allowances for

flexibility they can fit almost anybody in

the air force.

Dominant among the seven heads is the

central figure, designated as Head I, repre-

senting the average flyer, the grand mean

of all the measurements taken from the

1,871 specimens. By luck rather than by

artistic intent, he turned out to be the best-

looking one of the lot, with a strange re-

semblance to both the Prince of Wales and

the Arrow Collar Man as they appeared in

the early 1020's. As the composite of the

youngsters who have just lately been get-

ting their wings, he is the American Flyer:

1943 Model.

The creation of these heads, which is |

merely the first step in the building of life-

size manikins embodying airmen’s physical

characteristics, represents a fortuitous

blending of practical engineering and pure

science. They are the result of the collab-

oration of the young man who is probably

America’s foremost expert on the anatomy

of the gorilla, and the plastics-industry pio-

neer who invented the “Frank Buck hat,” |

now the standard tropical helmet for the

American and British armies.

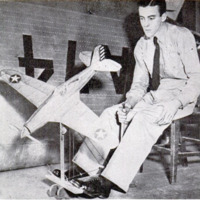

By last July, when the statistical analysis

of all the measurements was complete, the

anthropology team had dwindled to one

man, now a second lieutenant in the Air |

Forces, 20-year-old Dr. Francis E. Randall,

from New Philadelphia, Ohio. At Western

Reserve University, Randall had specialized

in comparative anatomy, working With |

Prof. T. Wingate Todd, who had the great-

est collection of gorilla skeletons in this

country. When Todd died, Randall con-

tinued his work. When the Japs struck at

Pearl Harbor, he was just putting the finish-

ing touches on his Harvard Ph. D. thesis, on

“Growth in Gorillas.” One gathers, talking

with him, that Randall felt pretty much |

out of things, as though his specialty were

far from wartime realities. But no sooner

had he finished his studies than the Army

grabbed him, to put his special training to |

work on the quest for the perfect mask.

When Lieutenant Randall presented his |

report last summer, senior officers looked at

it with a blank, bewildered stare. It com-

prised numerous closely typed pages of

little else but figures, about as intelligible

as Egyptian hieroglyphic. |

“Now you've got it, what are you going to

dowith i?" a general finally managed to say.

The men at Aero-Medical had a quick an-

swer. Turn these figures into sculptured

figures. The value of such figures was al-

ready apparent. At Wright Field they had

been using, as a model for trying out

assemblies of mask, goggles, earphones, and

helmet, an aluminum head which a sculptor

had made for the purpose. It was a good,

anatomical head of an individual, but

‘measurement now showed it to be far from

the norm of the Army aviator of today.

The thing to do was get a sculptor quick.

A noted sculptor was called on the long-

distance phone. How quickly could he pro-

duce five heads, made to measure? The

artist said it would take at least two

months; he couldn't do it a bit sooner. The

Army reluctantly said he wouldn't do. They

had to have speed.

Then a Wright Field engineer spoke up.

He knew a business man in Chicago who he

thought could do the job, G. Walter Bork-

land, president of the General Plastics Cor-

poration. As a sculptor Borkland was only

a talented amateur, who practiced the art

as a hobby, but he was a professional with

modeling clay. He was in the habit of de-

signing such things as transparent plastic

lighting fixtures, rapidly and strictly to

specification. He was ingenious, as shown

by his develop.

ment of a featherweight plastic sun helmet,

with a patent suspension that made one size

fit almost any man’s head. Moreover, he had

specialized for the last year in efforts to

design a satisfactory oxygen mask from

molded plastic. He knew the problem, and

would tackle it enthusiastically. He was

called on the telephone and told that he

was selected to make the heads, and make

them quick.

Lieutenant Randall hurried to Chicago

with his figures. In 16 working hours, with

Randall checking the measurements and

supplying anatomical criticism, Head I was

completed. In a little more than two weeks,

working with fanatical zeal, they had com-

pleted not five but seven heads. These

weren't art, but they were designers’ data

of the utmost importance. Cast in plaster

by technicians at the Field Museum, they

were in immediate demand. Sets were sup-

plied not only to all oxygen-mask designers

but also to the Navy, the Armored Force,

the Chemical Warfare Service, the R.A.F.,

and the air forces of Canada, Australia, and

South Africa. |

These plaster heads will be useful in the

designing of all kinds of aviators’ headgear

—masks, goggles, helmets, or even a one-

unit combination of all three. But the cru-

cial point at this time is the fitting of the

mask, and in this the most important

measurement is what is called the nasion-

menton dimension; that is the dimension

from the root of the nose to the tip of the

chin. The bony structure of these two parts

makes it necessary to get a relatively close

fit in order to make a leakproof mask. Over

the cheeks there is more leeway, taken up

by the flexibility of mask and flesh.

In the 1,871 men measured, the nasion-

menton varied from a maximum of 145

millimeters to a minimum of 102 milli-

meters, giving a span of 43 millimeters to

be fitted by as few different sizes as pos-

sible. But three quarters of the individuals

measured—1,453—had nasion-mentons of

122, 123, or 124 millimeters. Head I, the

grand mean, has this dimension at 123

millimeters; and the mask which fits him

will be a pretty good fit on the great ma-

jority of the men concerned.

Heads II and III present an optical illu-

sion. Though they don’t look like it, they

have the same nasion-menton as Head I.

But Head II, the hatchet-faced boy, is a

composite of the minimum values (that is,

the smallest measurements) found in the

1,453 individuals in the 122, 123, and 124-

millimeter group. Head III, the one which

looks like a Roman emperor or a big Slav,

is composed of the biggest measurements

found in the same group. These two will

be important when it comes to fitting hel-

mets, hat size varying from 6% to 7%.

From the mask standpoint, Heads IV and

V are next in importance to Head I They

represent, respectively, the average values

found in the lower 15 millimeter of nasion-

menton dimensions and those found in the

upper 16 millimeter. They represent only a

relatively small number of flyers, but in-

clude the longer and shorter thirds of the

measurement scale. It is possible that a

practical mask may be made in just these

three sizes.

Heads VI and VII are the out-sizes. Each

is a composite of the 16 faces falling in top

and bottom measurements. Roughly, they

are the long and short one percent.

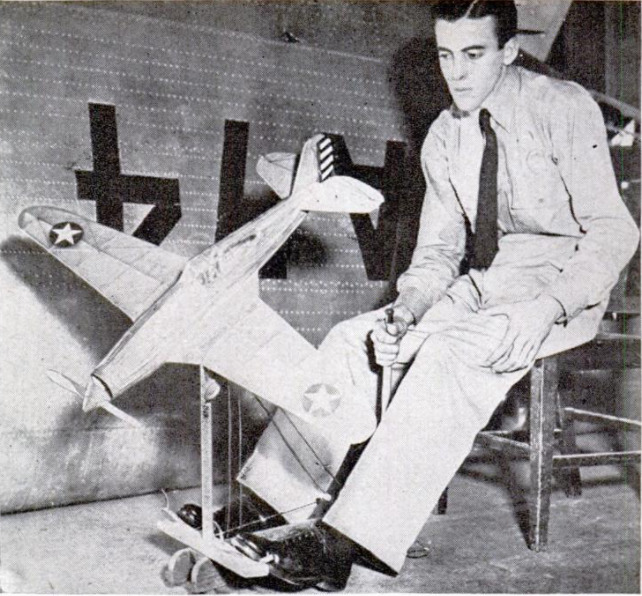

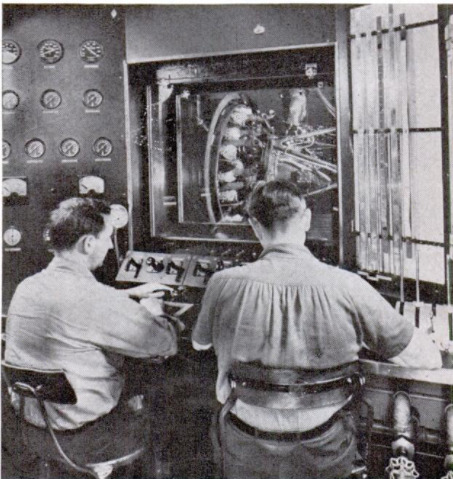

These heads are only a beginning in what

Randall and Borkland see as the new art

of “human engineering.” Today they are

working in a new frenzy, developing means

of properly jointing and reproducing three

models they have made of composite body

sizes of the same 1,871 flyers. These may

have great importance, as warplanes attain

still greater refinements of space-saving.

For instance, how large should a turret

be in a bomber? Every ounce of weight is

precious. If turrets were built with gun-

ners as models, that might lead to great

error and disaster. For it seems that gun-

ners are smaller than flying cadets. But if

a gunner is put out of action, it may well

fall upon the navigator, bombardier, or

copilot to take over the gun.

When pursuit planes dive at 725 miles an

hour, the limit of a pilot's physical abilities

are very nearly reached. No detail which

may increase the flyer's comfort or contrib-

ute in any way to his efficiency can be

overlooked. Up to now cockpits have been

built in accord with general notions of the

size and proportions of the men who use

them. With the Randall-Borkland figures

as guides, it will be possible not only to

have mass production of planes, but also to

have their fittings practically tailor-made

for the pilot.

-

Contributor (Dublin Core)

-

Hickman Powell (Article Writer)

-

William W. Morris (Photographer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-03

-

pages (Bibliographic Ontology)

-

96-104, 223-224

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

Popular Science Monthly, v. 142, n. 3, 1943

Popular Science Monthly, v. 142, n. 3, 1943