-

Title (Dublin Core)

-

Canada goes industrial

-

Article Title and/or Image Caption (Dublin Core)

-

Title: War turns an agricultural country into an arsenal as Canada goes industrial

-

extracted text (Extract Text)

-

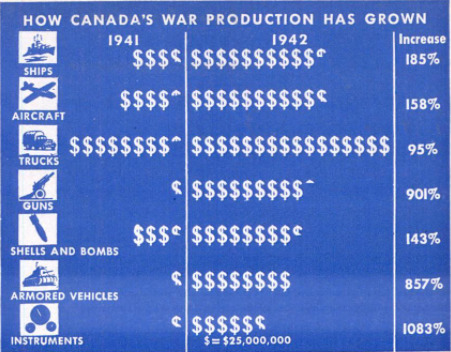

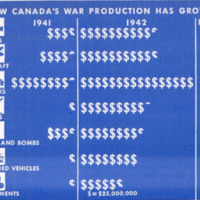

CANADA, for three centuries largely

. dependent upon its fields, forests, and

streams for livelihood, has industrialized

itself in the last three years. The war

emergency made it necessary, but Canada

will emerge from the war industrially

minded and industrially equipped.

Almost 1,000,000 of Canada’s population

of 11,500,000 are employed in essential war

industries and 650,000 more are in Canada’s

armed forces. Canada, almost an indus-

trial void in September, 1939, has since then

absorbed war orders aggregating more than

$6,000,000,000, and will spend $3,500,000,000

this year on the war, a sum about equiva-

lent to the entire national income of the

last peace year.

Almost every industrial plant in the

country has been put into war production

and dozens of new plants, put up on an

acreage basis, have sprung up. Prior to

1939 Canada imported all the materials

necessary for her small armed forces. The

fateful year 1939 found it not only short

of factories, but short of machines to build

the tools with which to turn out war sup-

plies. There was a shortage also of mechan-

ical experts.

There were no steel mills producing ar-

mor plate. Tanks which the United States

had built for the first World War had to be

imported for the early training of the

Canadian tank crews. The Canadian Navy

consisted of six destroyers and six mine

sweepers. Tool-making machines were im-

ported. Mechanical experts were borrowed.

Steel mills were equipped to turn out armor

plate. Not only the automotive industry,

but all industry possible was converted to

war use. A laundry, converted in peacetime

to an elevator factory, underwent its second

major operation and now is turning out

great quantities of two-inch smoke-bomb

throwers.

Canada started the war with the idea of

becoming self-sufficient. She has just about

realized her ambition, though peak produc-

tion will not come for some months yet.

The Canadian Navy has more than 500

vessels and they are Canadian-equipped

from steering gear to range finder. The

Canadian airplane industry, which turned

out about 40 craft a year in peacetime,

sends out 400 planes a month.

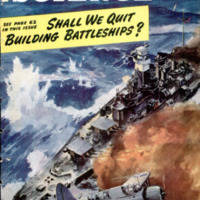

Except for battleships and the largest

guns, Canada’s war industries not only sup-

ply her war needs, but also turn out a large

surplus for her allies. Thirty percent of

Canada’s war output suffices for her own

armed forces, The rest goes to Russia, to

Great Britain, to the United States. Among

the United Nations, only the United States

and Great Britain surpass Canada in war

production.

From coast to coast, Canadian farmlands

have sprouted factories—shell-filling plants,

chemical plants, war shops of all Kinds.

C. D. Howe, Canadian Munitions and Sup-

ply Minister, said recently that more than

100,000,000 had been spent on construct

ing and equipping chemical plants alone.

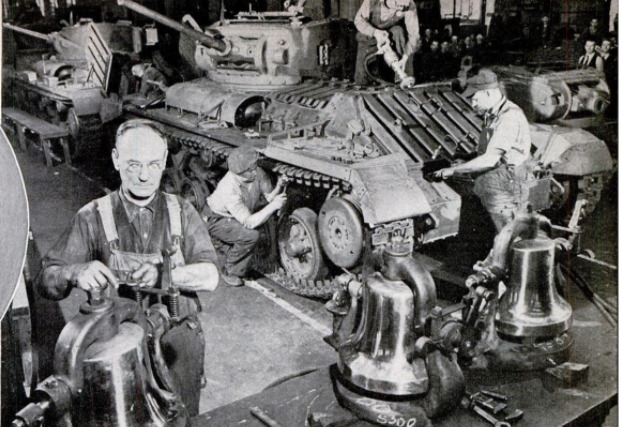

An elevator manufacturer has converted

his plant to the manufacture of the Bofors

antiaircraft gun, the bell-mouthed fast-

firer which stands guard in the United

States as well as in Canada and travels

far afield to shoot down its prey. Canada

was able to export these guns, capable of

firing 140 shots a minute, to the United

States before this country was equipped to

turn them out.

A soup-canning plant is making ammu-

nition. A marine engine factory turns out

not only ships’ boilers but also the Boys

antitank guns which can send a .55 caliber,

armor-piercing projectile into the most sen-

sitive and best protected parts of a tank.

Browning aircraft machine guns, auto-

matic rifles, and other weapons also are

coming from the boiler factory.

The automobile factories of Canada, sub-

sidiaries of American companies, are mak-

ing 100 different types of mechanized fight- |

ing vehicles, including mobile machine

shops. Locomotive shops produce tanks at |

the rate of three a day. A shoe manufac-

turer is making naval guns.

Gunsmithing is not a science that is mas-

tered in a short time. The skill and accuracy |

it demands is acquired only after years of

patient practice. Canadian gunsmiths were |

few when Canada went to war. Only once

before—during the first World War—had

Canadian industry been called upon to make

guns, and then it made only infantry rifles.

With few experts to call on, and only blue-

prints and working models to start with, |

Canada set out to make guns in 1939. There

were also the handicaps of a lack of machine

tools, and a lack of raw materials in the

form of steel and castings. Slowly these |

were overcome. Plants were converted,

machine tools were obtained by painstaking

hunting throughout Canada and the United |

States, men and women were recruited for |

the new industry and patiently trained to

do the work.

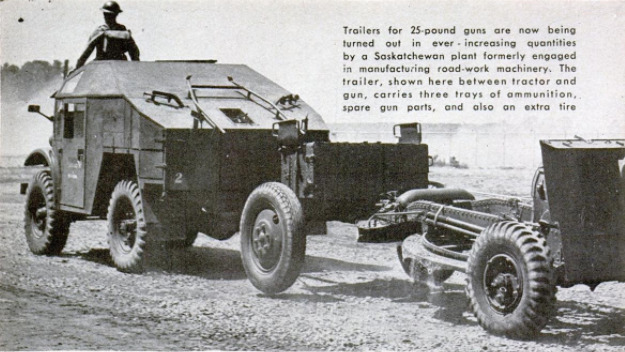

In last October alone, Canada’s produc-

tion of small arms was almost double its

entire production in 1941. Twelve types of |

small arms, 12 types of guns, and 16 types

of gun carriages were coming out of Cana- |

dian shops. Besides the Bofors guns, the

Browning aircraft machine guns, and the

Boys antitank rifles, 25-pounder field guns

of the most modern type were being pro-

duced by Sorel Industries, Ltd., at the rate

of 50 a month at $25,000 each and the pow-

erful 3.7 antiaircraft guns, which have sev-

eral thousand parts and weigh as much as

a city bus, were coming off the assembly

line at the rate set.

Canadian manufacturers also Were turn-

ing out the four-inch naval gun, the 12-

pounder naval gun, the two-pounder naval

gun, the .50 caliber Vickers naval machine

gun, the two-inch and three-inch trench

mortars, tank bomb throwers, naval depth-

charge throwers, Lee-Enfield rifles, Sten

submachine carbines, and Bren automatic

machine guns.

In machine tools, Canada did another

about-face. In 1939 she needed them desper-

ately. Since 1042 she has been exporting

them to Great Britain and the United States.

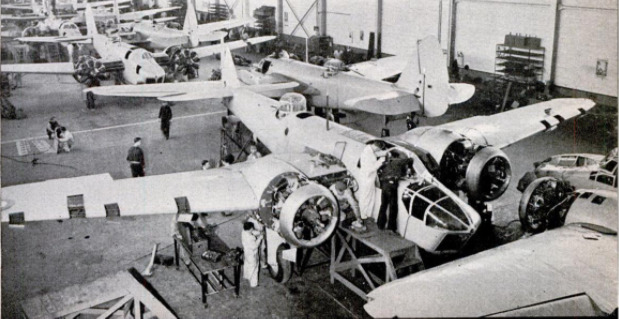

Nine types of planes are in production

in Canada, including the Curtiss Hell-Diver,

1,000 of which are being built for the United

States Navy. Another is the British Mos-

quito fighter-bomber, a speedy plane which

was on the “secret list” until recently. Ca-

nadian plants also are turning out the four-

engined Lancaster, a heavy bomber whose

block-busters have destroyed both German

and Italian industrial plants. Hurricanes,

Catalina PBY flying boats, and the Boling-

broke and Anson twin-engined bombers also

are in production in Canada, as well as

trainer planes. Propellers of both metal

and wood are turned out in such numbers

that the United States has been import-

ing them. The Canadian aircraft industry,

which employed about 1,000 persons before

the war, now keeps more than 55,000 men

and women busy. To help the aircraft pro-

gram, Canada has, since the start of the

war, built the largest aluminum plant in

the world to help supply both her own war.

needs and those of the United Nations. The

current capacity of this enormous plant is

already greater than the world's total out-

put of aluminum during the year 1939.

Canada had never made any optical glass

before she entered the war. Imports from

Great Britain, Germany, and the United

States had been relied upon to meet her

needs. A large part of these imports were

cut off just at the moment that Canada

was going to need the glass for range

finders, gunsights, periscopes, and other

instruments. The government-owned Re-

search Enterprises, Ltd, was set up in

Toronto to meet the emergency and within

eight months of the start of the project the

first optical glass was produced.

In a relatively short time the plant not

only was meeting Canada’s needs, but also

was sending its instruments to Canada’s

allies. Its field soon was widened and it

is now manufacturing scientific equipment

of various sorts, including communications

instruments and articles which still are on

the “secret list,” such as radio locators.

The plant turns out optical instruments of

all kinds; navigating instruments for

planes, ships, and fighting vehicles; and

fire-control instruments for the navy.

British shipyards used to supply what

ships were needed for Canada’s ocean and

Great Lakes commerce, and Canada’s ship-

building efforts were confined largely

river, harbor, and fishing craft. Canada

now has 21 major shipyards and 58 smaller

ones. Canada is building 300 cargo ships

of 10,000 tons and a number of 4,700-ton

cargo vessels, utilizing the prefabrication

method. Canada also is turning out de-

stroyers, corvetes, mine sweepers, subma-

rine chasers, and patrol boats of various

types. At least one of the corvettes was

built for the United States. In the latter

part of 1942, Canada’s ship-building pro-

gram, according to Humphrey Mitchell,

Canadian Labor Minister, surpassed that of

Great Britain.

Canadian tanks, both 18-tonners and 30-

tonners, have been fighting on the Russian

front for months and have received high

praise from the Russians. Both Canada

and Great Britain depend upon the prod-

uct of new mercury mines which have

been discovered and developed in Canada

since 1939. A mew magnesium production

method, developed in Canada’s national

Research Council by Dr. L. Pidgeon, is in

use in the United States, and new iron-ore

deposits in the Dominion are furnishing

their quota of the North American output.

While in the throes of this mushroom in-

dustrial development, Canada has kept her

agricultural production at a record height

and has been able not only to feed herself,

but to export to Great Britain, Russia, and

other countries. It is her intention to have

agriculture and industry march abreast in

peace as in war.

-

Contributor (Dublin Core)

-

James Montagnes (Article Writer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-04

-

pages (Bibliographic Ontology)

-

78-81

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

-

Spatial Coverage (Dublin Core)

-

Canada

Popular Science Monthly, v. 142, n.4, 1943

Popular Science Monthly, v. 142, n.4, 1943