-

Title (Dublin Core)

-

America will win the battle of Kilowatts

-

Article Title and/or Image Caption (Dublin Core)

-

Title: America will win the battle of Kilowatts

-

Subtitle: Our gigantic system of dams and powerhouses pump the lifeblood into vital war industries

-

extracted text (Extract Text)

-

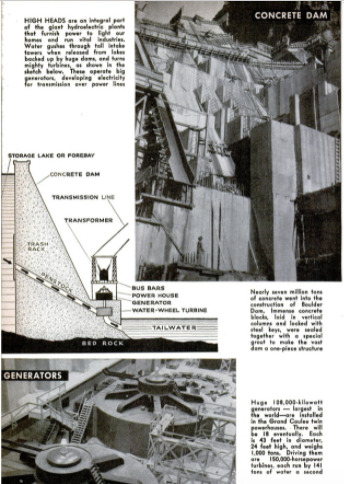

ELECTRICITY is the lifeblood of modern

war production. We must have it in

vast quantities to produce aluminum for

airplanes and magnesium for bombs; to

heat-treat steel for gun barrels, ships’

plates, and tank armor; for the production

of chlorine and other chemicals. We must

have it to run the hundreds of thousands

of machine tools which are turning raw

metals into finished weapons. Just as im-

portant, we must have it to keep working

the everyday services on which depends

the sustained drive of our war effort—to

run streetcars and elevators; to keep radio

stations on the air and telephone and tele-

graph systems in operation: to light fac-

tories, mines, and streets.

In the crowded, vulnerable industrial

areas of Germany, power-generating sta-

tions are among the most carefully guard-

ed installations—and the favorite targets of

the R.A.F. One bomb neatly placed on a

German powerhouse can do more to cut off

the flow of arms and munitions to Hitler's

war machine than a score dropped on sepa-

rate factories. |

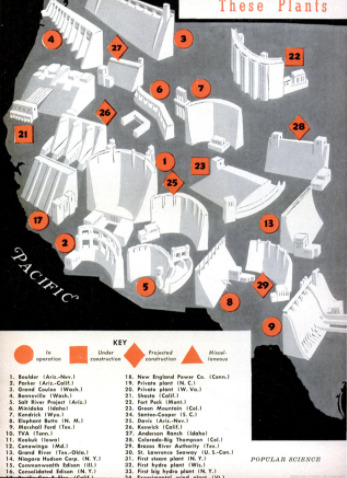

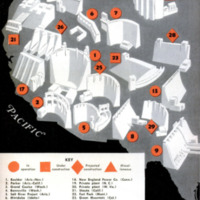

In this battle of the kilowatts, America

enjoys an immense advantage in the huge

hydroelectric plants that dot the country

from Grand Coulee on the Columbia to

Boulder Dam on the Colorado and from;

the falls of Niagara to the valley of the

Tennessee. On a thousand rivers and

streams, large and small hydroelectric

plants add their contributions to the mighty

torrent of electric power that is helping us

win the war. |

Late in 1942 we were using electric pow-

er at an all-time high of about 240 billion

kilowatt hours a year. Although only 30

percent of our generating plants are hydro-

electric, these are producing 40 percent of

our electricity. That they are of the great-

est importance in our war effort was proved

by last year’s increases over 1941 in the use

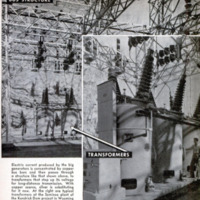

of electric power. On the Pacific Coast,

where nine tenths of the power generated

is hydroelectric and nearly all war indus-

tries are served by water-powered plants,

the increase was twice the average increase

for the nation. The adequate supply of low-

cost power assured by hydro-electric de-

velopments is an important consideration in

the location of war plants.

The proportion of

hydroelectric gener-

ating plants is increas-

ing steadily. Since

the earliest days of

the 60-year-old elec-

tric power industry

generators have been

driven by both steam

and water. Thomas A.

Edison opened the

first steam-powered

central station on

Pearl Street in down-

town New York in

September of 1882,

and a few days later

opened the first hy-

droelectric plant on

the Fox River at Ap-

pleton, Wis. But until

about 25 years ago,

because of the then

unsolved technical dif-

ficulties and high cost

of transmitting elec-

tric current over long

distances, hydroelec-

tric development had to be confined largely

to localities where water power was fairly

close to potential users of the electric pow-

er to be generated by it. Consequently,

more steam than water-power plants were

built. But methods

have been improved

until electric power

can be transmitted

economically for 300

miles, and now half

of the power-produc-

ing facilities under

construction are hy-

droelectric—nearlyall

of them Federal or

state owned.

Hydroelectricplants

are expensive to build,

but once built they

cost much less to op-

erate than do steam

plants. Little labor is

needed to keep them

running, they burn no

coal, and their eco-

nomic life is much

longer than the 20-

year average of steam

plants. Their most se-

rious disadvantage is

that sometimes their

power output is less

ened by droughts, but on many rivers

storage dams built upstream from the pow-

er dams assure uninterrupted production.

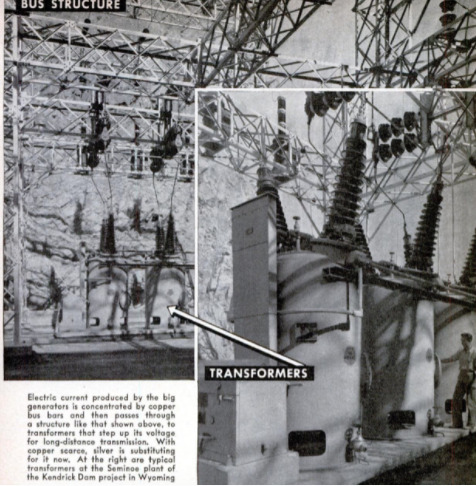

The hardest-to-break wartime bottleneck

in increasing hydroelectric power produc-

tion is the procurement of

turbines and generators.

They take about two

years to build and there

are only a few manu-

facturers who have the

equipment and highly

skilled workers neces-

sary for the job, Unfor-

tunately, these manufac-

turers also are the only

ones who can build

steam turbines for war-

ships and cargo vessels,

and the War Production

Board has ordered work

stopped on all power-

house equipment that

will not be finished by

early next year.

The mammoth dams

which tame and harness

mighty rivers for the

generation of electric

power are among the

most impressive of the

works of man, and their

building is made possible

only by brilliant pioneer

work in engineering. The

two most spectacular are,

of course, Boulder Dam

on the Colorado River

near Las Vegas, Nev., and

Grand Coulee on the

Columbia in the state of

‘Washington. One is the largest individual

power plant in operation anywhere in

the world; the other, when completed, will

dwarf it.

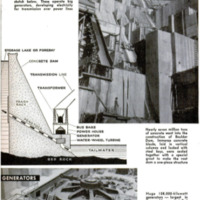

Boulder Dam is geared now to a generat-

ing capacity of 952,300 kilowatts with 12

of its projected 17 generators in action. It

produces over 31/3 billion kilowatt hours

of current annually, transmitting much of it

to plane factories in the Los Angeles area

over a 266-mile 285,000-volt double-tower

line—longest in existence and unparalleled

for high voltage. Grand Coulee, in opera-

tion only since 1941, has a present capacity

of 386,000 kilowatts, and two more 108,000-

kilowatt generators will go into service this

year. When all 18 are installed, Grand Cou-

lee will have a capacity of close to two mil-

lion kilowatts, or 13 billion kilowatt hours

a year. It is the biggest engineering struc-

ture that has ever been built by mankind.

The 115,000-horsepower turbines at

Boulder Dam are turned by water gushing

through four skyscraper-high intake towers

from Lake Mead, the largest man-made

reservoir in the world. Grand Coulee’s 150,-

000-horsepower turbines are fed by the

overflow of a 1,650-foot spillway which

forms a waterfall twice as high as Niagara.

And both these great plants are but units

—thongh the most impressive—in their

systems Boulder Dam is supplemented by

Parker Dam, 155 miles downstream, and

Davis Dam, midway between them, will be

finished after the war. Grand Coulee is in-

terconnected with Bonneville Dam, com-

pleted by Army Engineers in 1938 at the

head of tidewater on the Columbia. Seven

more dams are proposed to raise the Colum-

bia output to the

total of 90 billion kilowatt hours a year.

Boulder Dam and Grand Coulee were

built under contract with the Bureau of

Reclamation through a merger of six Pa-

cific Coast companies of which Henry Kai-

ser, more recently of ship-building and

cargo-plane fame, was a leader. Boulder

was in operation in 1936, six years after the

plans were drawn, two years ahead of

schedule. Construction required first the

building of railroads and motor roads and a

town for 5,000 workers and their families.

Before excavation for the foundation of the

dam, the river had to be diverted through

56-foot-diameter tunnels blasted through

three miles of canyon walls. Seven million

tons of concrete went into the dam itself,

poured into blocks 25 to 60 feet square and

cooled by ice water running through em-

bedded pipes. These blocks, piled in vast

vertical columns and locked together with

steel keys, were converted into a solid unit

by running a special grout concrete be-

tween them.

In addition to Boulder and Grand Coulee,

between 1908 and 1941 the Bureau of Recla~

mation built 26 smaller hydroelectric plants

on 15 projects in 11 Western and South

western states. Their aggregate generat-

ing capacity is close to a quarter million

kilowatts. Several large dams are under

construction—the biggest is 602-foot-high,

375,000-kilowatt Shasta Dam on the Sace

ramento River, keystone of the Central Val-

ley Project in northern California. It is

over three-quarters completed, but gener-

ators ordered for it have been installed at

Grand Coulee.

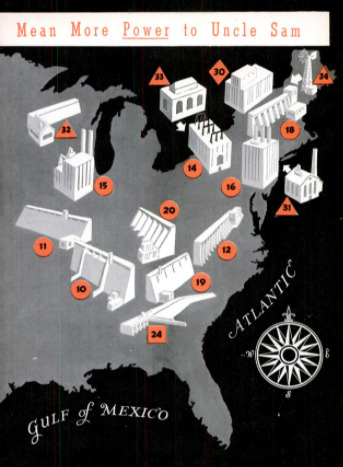

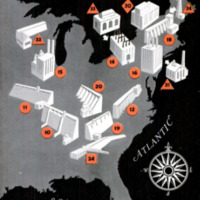

While our most spectacular water-power

developments are in the West, our largest

present hydroelectric system is on the other

side of the continent. It is composed of the

dozen interconnected power-producing dams

of the Tennessee Valley Authority on the

Tennessee River and its tributaries in

Tennessee, North Carolina, and Kentucky.

They have a total generating capacity of

nearly 1 1/2million kilowatts, more than 70

percent of which goes into war production

in the great aluminum, chemical, electro

metallurgical, munitions, and industrial

plants of this vital war-production area.

The oldest of these plants and the one

with the largest generating capacity—288,-

000 kilowatts—is Wilson Dam, started in

1918 to supply power to the World War

nitrate plants of the Muscle Shoals area.

Pickwick, Norris, Wheeler, and Chicka

mauga dams all have generating capacities

of over 100,000 kilowatts. Several new

dams are under construction—among them

the 450-foot Fontana Dam on the Little

Tennessee River in North Carolina, which

will be the highest dam east of the Rocky

Mountains and will have a generating

capacity of 200,000 kilowatts; Kentucky

Dam on the Tennessee River near Paducah,

Ky. which will be the biggest dam east of

the Mississippi and will have a generating

capacity of 126,000 kilowatts; Appalachia

Dam on the Hiwassee River; and Douglas

Dam on the French Broad River.

A number of large-scale hydroelectric de-

velopments have been undertaken by state

power authorities. The 130,000-kilowatt.

Bantee-Cooper project is nearing comple-

tion in South Carolina. Work has been

started on important developments on the

Lower Colorado and Brazos rivers in Texas.

‘While the greatest developments, requir-

ing enormous capital investments, have

been financed with the public's money, there

are many important privately owned hy-

droslectric plants. The largest ia the 178,

450-kilowatt. Schoelkopf Station of the Ni-

agara_ Hudson Power Corporation. The

Comerford plant of the Connecticut River

Power Company has a generating capacity

of 166,000 kilowatts, and is the largest in

New England. Conowingo Dam, In northern

Maryland, produces 11/3 billion kilowatt

hours of power a year. Operated In con-

Junction with two sother plants farther up

the Susquehanna River, it supplies power

to the vital Baltimore, Philadelphia, and

southern New Jersey industrial areas.

The end of the war almost certainly will

be the beginning of an era of tremendous

Government-financed hydroelectric develop-

ment. The Bureau of Reclamation will com-

plete projects on which it has suspended

work, and start several new ones. Several

states will go ahead with important power-

production projects now authorized. Hydro-

electric developments may be made more

attractive to private capital by advances in

the field of high-voltage power transmission

which will make possible the low-cost trans-

mission of water-power-generated electrici-

ty to localities many hundreds of miles from

where it is produced. A way may even be

found to stockpile electricity for use when

it is needed—an advance which would re-

duce production costs by obviating the

need for expensive stand-by generating

equipment which is used only when current

requirements are abnormally high.

-

Contributor (Dublin Core)

-

Arthur Grahame (Article Writer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-04

-

pages (Bibliographic Ontology)

-

108-113, 216, 218

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

Popular Science Monthly, v. 142, n.4, 1943

Popular Science Monthly, v. 142, n.4, 1943