Advanced systems for painting planes

Item

-

Title (Dublin Core)

-

Advanced systems for painting planes

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Painting big planes

-

extracted text (Extract Text)

-

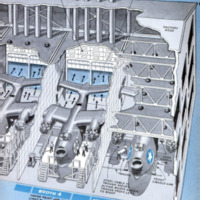

LARGE enough to accommodate the body

suructures, complete with wing stubs,

engines, and tail assembly, of five big Navy

patrol planes at once, a block-long shop in

the Glenn L. Martin plant helps speed air-

craft to the fighting fronts. As they move

through the building-within-a-building, fly-

ing boats receive three paint jobs and two

other finishing treatments in assembly-line

style.

Each operation, performed in a separate

booth, takes approximately the same time.

To assure this, men and women workers

may be shifted as needed from one booth to

another, When work in all booths is done,

out comes a finished plane body at the end

of the line.

Now the whole scene shifts. Partitions,

which have separated the booths, telescope

toward the rear like the panels of folding

household screens. This clears a pair of

railway tracks running lengthwise through

the building. Front and rear

cradles, supporting each fuse-

lage, rest on these tracks. Now,

a special tow car is made fast

between the cradles and is at-

tached to an endless cable. An

electric-powered winch draws

ahead the cable, tow car,

cradles, and plane body, until

each fuselage has been ad-

vanced to the next booth. The

same procedure brings a new-

ly assembled plane body, from

outside the building, past a

telescoped wall into Booth 1.

With wall and partitions back

in place, the production cycle

goeseon.

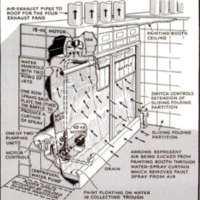

Accompanying drawings

show what happens in the

booths. The yellow zinc chro-

mate coat provides resistance

to corrosion. A finishing coat

of enamel, bluish slate above

and a lighter shade of bluish

gray beneath, makes the plane

difficult to detect against sea

or sky.

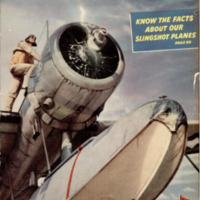

After the main part of the

plane leaves the booths, the

wing panels, which have been

painted in another part of the

plant, are attached, instru-

ments are checked, armament

is installed, and another PBM-

3 Mariner is ready for its test

flight.

To avoid fire hazards from

paint solvents, and to protect

the workmen by making the

air in the booths purer to

breathe, each of the compart-

ments is equipped with a cur-

tain of water through which

powerful fans constantly ex-

haust spray-laden vapors. Val-

uable pigments, instead of

disfiguring the surrounding

territory, are trapped in the

water sprays and recovered.

Although only Navy patrol

planes are being painted in the

shop, which is the largest of

its kind in the world, it could

handle any U.S. warplane ex-

cept the giant B-19.

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1943-05

-

pages (Bibliographic Ontology)

-

94-96

-

Rights (Dublin Core)

-

Public Domain (Google Digitized)

-

Archived by (Dublin Core)

-

Matteo Ridolfi

-

Marco Bortolami (editor)

Popular Science Monthly, v. 142, n. 5, 1943

Popular Science Monthly, v. 142, n. 5, 1943