-

Titolo

-

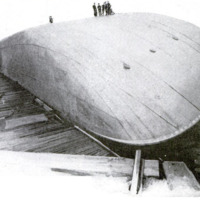

How the Americans managed to get a lake vessel, which was too large to navigate North America canals and rivers, to the Atlantic Ocean

-

Article Title and/or Image Caption

-

Title: The Story of a Big Ship and a Little Lock

-

Subtitle: Getting a fifty-foot boat through a forty-four-foot canal

-

extracted text

-

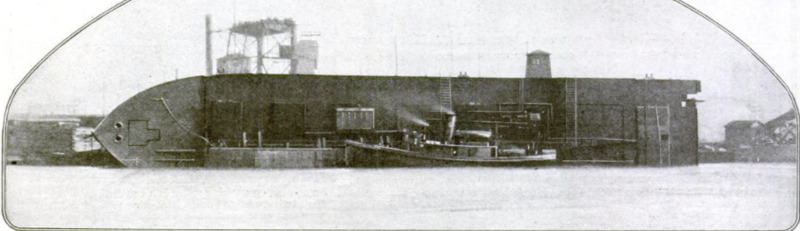

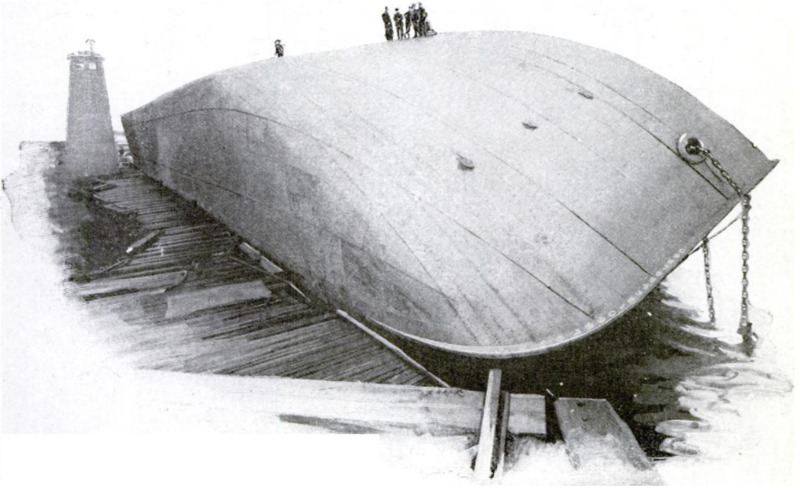

ONE hundred and ninety lake ves-

sels were taken over by the

United States Shipping Board

when America entered the war. Forty-

eight of these were brought out to the

Atlantic seaboard by way of the Wel-

land Canal around Niagara Falls and

down the St. Lawrence river before the

closing in of the ice in the winter of

1917, and thirty-five more subsequent

to the opening of navigation in the

spring of 1918.

Many of these vessels were longer

than the locks in the canal. It was

not a difficult task to cut these in

half, bulkhead the open ends, and take

them through in two parts. But the

Charles E. Van Hise (460 feet long,

50 feet beam, and 43 feet 8 inches from

keel to gunwale) presented a more

difficult problem. She was not only

t00 long, but also too wide. Her beam

of fifty feet was six feet more than the

width of the locks.

We Need the Ships

Ships are needed mow almost as

badly as they were when the submarine

peril was at its height. Hence the prob-

lem of getting the Van Hise through

was put squarely before the engineers

of the Shipping Board for solution.

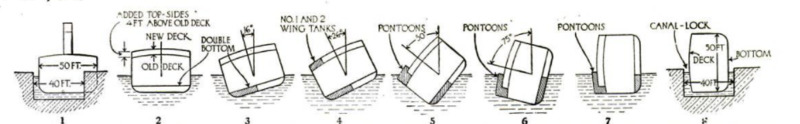

They accomplished their task with

the cutting of the ship in but one place.

This was amidships, just as in the boats

that had a beam less than the width of

the locks. But with that operation

the similarity ended. The narrower

boats were taken through the locks on

an even keel, but the Van Hise had

to be tipped over on her side and

floated on her beam ends, with her

deck vertical to the water.

No other ship approaching the Van

Hise in size had ever to be manipulated

in a like manner. The engineers had

no precedent to follow.

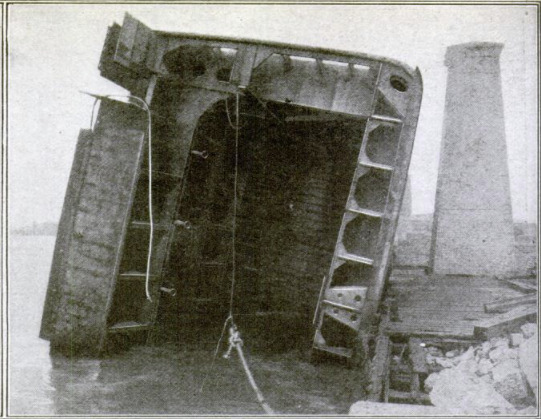

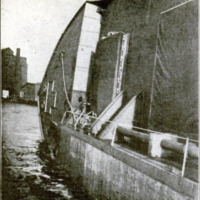

Bow and Stern Separated

The bow was cut in two, turned on

its side, and passed through one lock

of the canal on December 5 last. The

stern section, containing the engines

and boilers, was handled separately.

Alter proving that the daring plan of

handling the Van Hise was successful,

the engineers decided that the season

was too far advanced to make it safe

to send the ship on her strange voyage.

She is wintering in Lake Erie and

will make the trip through the canal in

the spring.

The first step in the work on the

bow section was to bulkhead the cut

end, and then to make the deck water-

tight by sealing all the hatches and

covering all the portholes and other

openings above the waterline on the

side of the ship that would be under

the water when the vessel was turned

on her side.

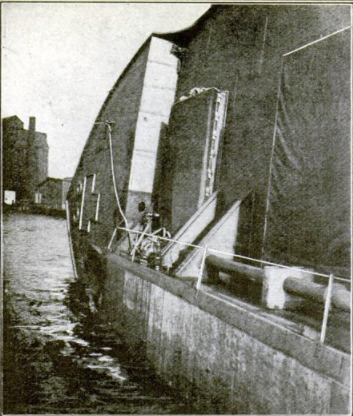

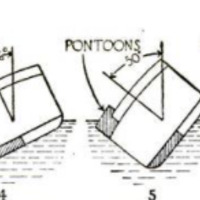

Over on Her Side

The next step was to mount six

adjacent wood and steel pontoons

about nine and one half feet long and

between five and six feet deep, on

the upper deck of the boat between

the forecastle and the rise of the

bridge-deck amidships. These pon-

toons were mounted entirely on the

deck and extended clear to the side

of the hull, which would be under

water when the vessel was turned

over. |

The boat was now ready for the,

turning operation. Gradually the

pontoons and other tanks inside of the

vessel were filled with water, so that

she became unbalanced and turned

over on her side without any ill effects,

much as you turn over in the water

while swimming.

The inner bottom on the side toward

the turn was first filled with 172 tons

of water. This tilted her slightly.

Then 130 tons of additional water!

ballast was added in the side tanks,

and finally 466 tons more was pumped.

into the pontoons, thus tipping the’

boat until she lay over on her side.

Tn addition to this total of 768 tons,

of water, 135 tons of equipment was|

used as ballast. Since the pontoons

weighed 105 tons, the grand total of

1,008 tons was required to turn the

forward section, weighing 1,700 tons.’

The water and other ballast made

the boat float with a draft of four-

teen feet.

The turning operation was done, not’

in the locks, but in Lake Erie near;

Buffalo. The bow section was first;

towed upright to a suitable place.

Then the pumps were started, steam

being furnished by accompanying tugs,

and after five hours the tanks and

pontoons were filled, whereupon the

section rolled over perfectly on its side.

It was then towed back to Buffalo, |

where leaks and other minor repairs

were made. This done, it was towed |

to Port Colborne, the entrance to the

canal. In the spring it will go on

through the locks. |

Gelling the Stern Through

The stern section will be floated

through in a similar manner. It was

first planned that the two sections

should be righted before being joined

together again. But now the en- |

gineers, F. A. Eustis, H. N. Herriman, |

and. W. F. Powers, hope to. join the

two halves as they lie floating on their

sides, and without putting them into |

dry-dock.

First of all, they will calk and paint

that portion of the vessel that is out of

water; then they will roll her over, |

remove the pontoons, shift the ballast,

and complete the other side in the

same manner. |

-

Autore secondario

-

Joseph Brinker (Article writer)

-

Lingua

-

eng

-

Data di rilascio

-

1919-03

-

pagine

-

54-55

-

Diritti

-

Public domain (Google digitized)

-

Archived by

-

Davide Donà

-

Marco Bortolami (editor)