-

Title (Dublin Core)

-

Bullet-resistant glass

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Transparent armor...shields for sky fighters

-

Subtitle: Layers of glass and plastic, like your car's safety windows, resist shattering by bullets

-

extracted text (Extract Text)

-

THINGS were getting hot for the rear gun-

ner of an American medium bomber over

Tunisia, one day a few months ago. A Mes-

serschmitt was on his tail, and 20-mm. explo-

sive shells whizzed closer and closer, until

one of them smacked right against his win-

dow. By all the rules, that should have

ended the gunner’s career. The fact is that

he wasn't even scratched.

Incredible as it seems, a piece of glass

saved his life. The window was a typical

installation of a modern aviation material

for protecting combat flyers, which Ameri-

can factories are now turning out on a mass-

production scale. Cautiously, its makers

and the armed forces call it “bullet-resistant

glass.” They emphasize that it was never

intended to stand up against explosive shells,

though it has done so on occasion. What the

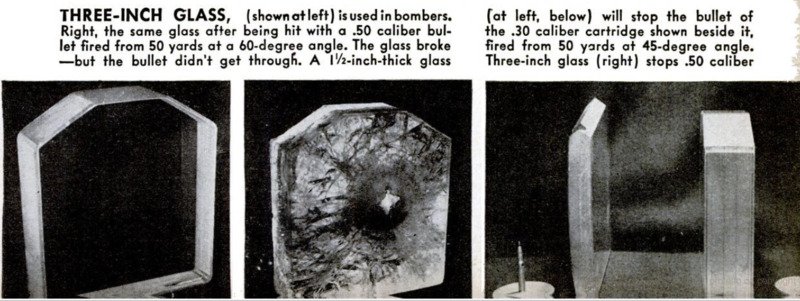

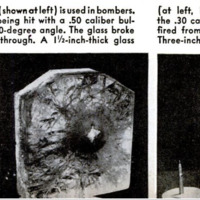

manufacturers do say, and rigid Army and

Navy specifications demand, is that a block

of this glass 5% inches thick will stop a .50

caliber armor-piercing bullet, striking head-

on, at a range of only 50 yards. And that

thickness may be considerably reduced if

only oblique hits, by far the more frequent,

are to be guarded against.

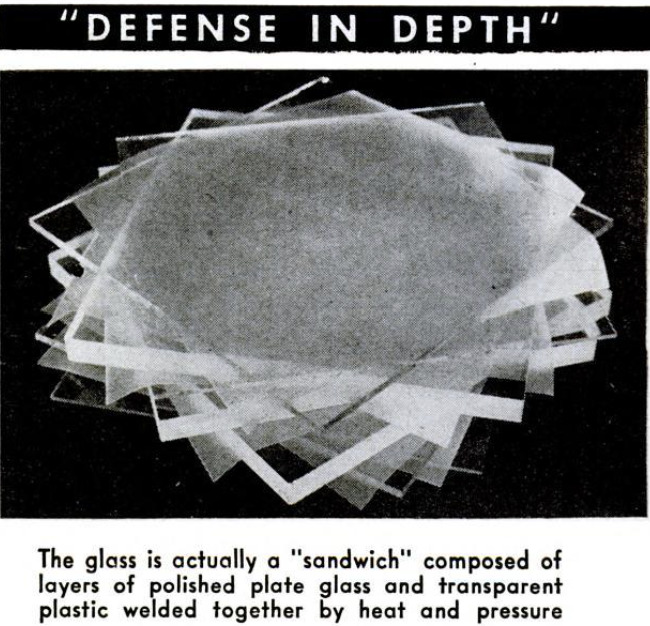

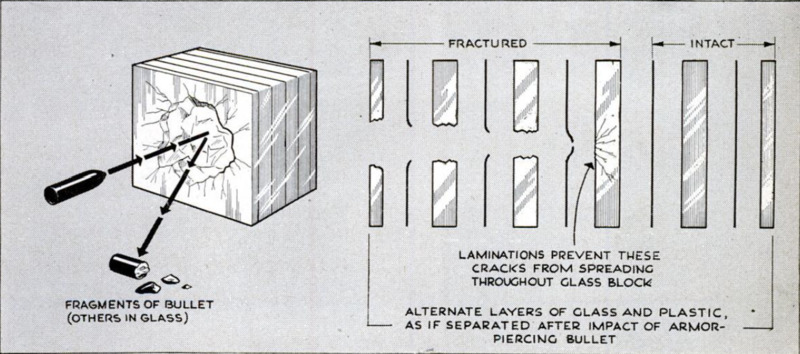

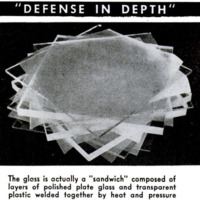

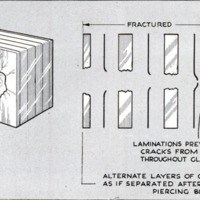

In principle, bullet-resistant glass takes

after its ancestor, automobile safety glass.

Both consist of multiple sheets of polished

plate glass, separated by films of transpar-

ent plastic. These intervening layers of elas-

tic material are bonded to the glass by heat

and pressure. They serve to prevent a crack

from spreading through the entire thickness,

confining it to a part of the “sandwich.”

Also, they oppose radial cracking and shat-

tering.

Much depends on the type of plastic used.

The kinds first employed for auto safety

glass had drawbacks, of minor importance

to motorists but serious to airplane crews.

For example, long exposure to sunlight

tended to discolor the plastic—only slightly

in a thin window, but considerably in one of

enough layers to resist bullets. Another dif-

ficulty was that extreme cold made the plas-

tic brittle, robbing it of resiliency and

weakening the bond between layers of glass.

Not long before the war, chemists perfected

a synthetic plastic, known as plasticized

vinyl butyral, which met all objections.

Successfully tried out in automobiles, and

then in armored cars used for transporting

valuables, bullet-resistant glass was fully

developed just in time for war needs, which

now consume the entire supply. After hos-

problem. One square foot of the material,

one inch thick, tips the scale at 13 pounds.

How to make windows as light in weight

as possible, therefore, is a question that has

preoccupied makers and users. One solution

has been to keep down their dimensions and

mount them close to the eyes of a flyer so as

not to restrict his field of vision. A window

as small as a foot square gives the tail gun-

ner of a bomber plenty of view to sight his

weapon. Likewise, a small block of the glass

may be mounted within the cockpit of a

fighter, just in front of the pilot's head.

Front-line observers, reporting on the pro-

portion of air casualties caused by bullets of

various calibers, have helped to show the

minimum of glass thickness consistent with

safety. In the same way, the angle at which

most bullets strike a craft of a given type

has come in for study. According to report,

the Army wanted to find out the chances of

one fighter pilot shooting another while the

two planes approached head-on. Two skilled

pilots took up planes and tried it, just short

of actually shooting. To make sure that

their paths would coincide, they came at each

other with a straight highway for a guide.

With the terrific speed of such planes, both

pilots concluded, the fleeting interval be-

tween coming into range and swerving to

avert a midair collision would have been too

short to get in a single machine-gun burst.

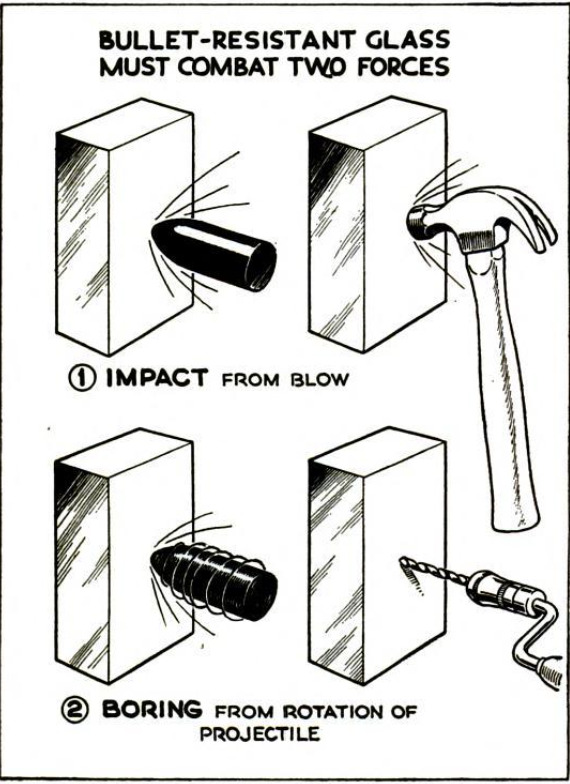

The importance of this finding may be

judged by the fact that if a piece of bullet-

resistant glass 214 inches thick will stop a

bullet heading straight for it, its thickness

may be reduced to 13 inches to turn away

a bullet at 45 degrees, and to 1% inches for

a hit at an angle of 30 degrees with the

glass.

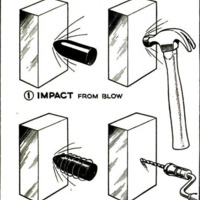

Currently being investigated is the possi-

bility of using two or more blocks of bullet-

resistant glass, with the combined thickness

of a single layer, but set some distance apart

and at an angle to each other. One hoped-

for effect would be to tumble the bullet in

flight, so that it would tend to sideswipe the

second block instead of striking nose first.

Even a deviation as small as five degrees re-

duces the penetrating power of a bullet.

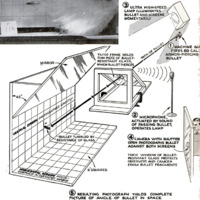

Ultrahigh-speed photographs made in the

Creighton, Pa., research laboratories of the

Pittsburgh Plate Glass Company—reveal

what happens to a bullet after it penetrates

relatively thin sheets of the material

Through a cleverly arranged set-up, a single

picture tells the whole story.

At one end of a basement test range, the |

experimenters fire a single round from a

standard aircraft machine gun, whose mount

is embedded in concrete. The bullet bores

through the piece of glass, 50 yards away.

An instant later, its picture is taken as it

passes a pair of vertical and horizontal

sheets of cardboard ruled with two-inch

squares. To do this, the camera shutter is

left open in the darkened range. A micro-

phone, four feet nearer to the gun than the

camera, picks up the sound of the passing

bullet. This serves as the trigger to set off

an Edgerton-type lamp, which stabs the bul-

let and marked screens with 2/1,000,000 of a

second of illumination.

Studies of the pictures show that an in- |

clined plate tumbles a bullet effectively—

and that even a thin vertical plece of bullet-

resistant glass has some effect. The views

also show that laminated sheets as thin as |

half an inch can rip the copper jacket from

a bullet, and even smash the projectile into

fragments. From such’ fundamental re-

search, advanced arrangements of bullet

resistant glass are expected soon to emerge

that will save the lives of still more airmen.

ALDEN P. ARMAGNAC,

-

Contributor (Dublin Core)

-

Alden P. Armagnac (article writer)

-

Robert F. Smith (photographer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1944-02

-

pages (Bibliographic Ontology)

-

74-77

-

Rights (Dublin Core)

-

Public Domain (Google digitized)

-

Archived by (Dublin Core)

-

Lorenzo Chinellato

-

Marco Bortolami (editor)

Popular Science Monthly, v. 144, n. 2, 1944

Popular Science Monthly, v. 144, n. 2, 1944