How airplane engines are tested

Contenuto

-

Titolo

-

How airplane engines are tested

-

Article Title and/or Image Caption

-

Title: High Altitudes Brought to Sea-Level

-

Subtitle: How airplane engines are tested

-

extracted text

-

IF you wish to ascertain whether a

substance will melt at a tempera-

ture of 400° Fahrenheit, what do

you do? Simple enough: you make a

practical test by heating the substance

to a temperature of 400 degrees.

It is not always easy to make practi-

cal tests under the correct conditions.

Take engines, for instance. It is a

simple enough matter to try out a

stationary engine. Its environment

remains practically unchanged. There

may be some variations in tempera-

ture, air-pressure, humidity, and other

atmospheric conditions; but these

changes are, as a rule, neither abrupt

nor formidable enough to be of material

influence upon the efficiency of the

engine.

Tests for Airplane Engines Different

It is different, however, with the

engine of an airplane. Under ordinary

working conditions, the engine of an

airplane rising to high altitudes may

pass from one extreme of air-pressure

and temperature to the other in a few

minutes. If we wish to ascertain

what effect on the efficiency of the

engine such varying conditions may

have, we must try out the engine under

conditions closely resembling those

under which it would be expected to do

its work. It is obviously desirable to

make those practical tests before the

engine is permanently installed in an

airplane.

For the purpose of testing airplane

engines under conditions closely re-

sembling those of actual flight, the

Bureau of Standards at Washington

has established a testing plant com-

monly known as the “Altitude Lab-

oratory.”

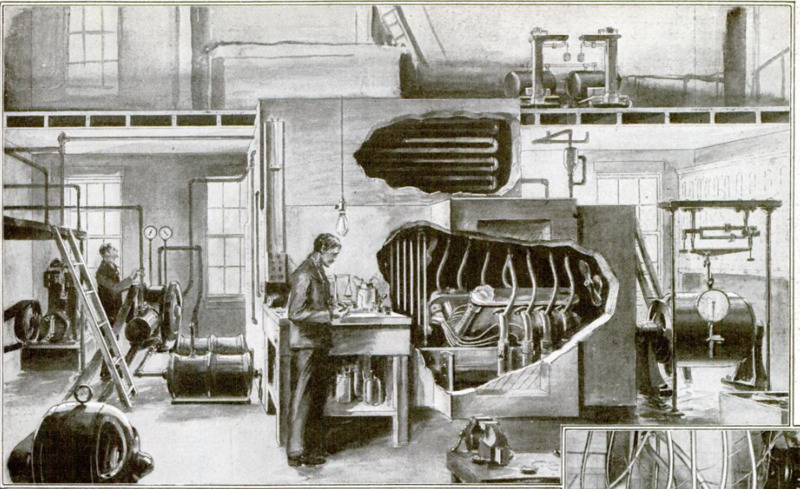

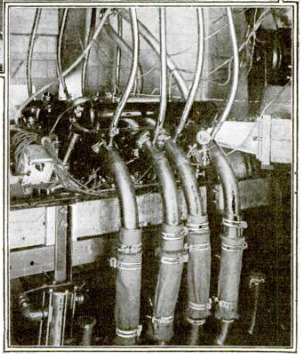

In the Altitude Chamber

The testing chamber, in which the

engine is mounted in a manner re-

producing its mounting in an airplane,

is a room fifteen feet long, six feet wide,

and six and one half feet high, with

concrete walls a foot thick. These

walls are insulated on the inside with

cork.

The dynamometer for measuring the

power developed by the engine is out-

side of the chamber, and so are the

scales for weighing and continuously

registering the amount of fuel used, the

water-meter for the cooling water, the

gas-meter for the air intake, the gage

for showing the exact degree of air-

rarefication within the chamber, and

the dials of the electrical thermometers

registering the temperatures at differ-

ent points on the inside of the chamber.

The chamber is chilled by an ordi-

nary ammonia refrigerating plant,

and, to produce a wind effect, the icy

air inside is violently agitated by

electric fans. Two electric motors of

forty and fifty horsepower drive the

refrigerating and rarefying plants. To

assist in the maintenance of a low air-

pressure in the chamber, cold water is

injected into the exhaust.

The dynamometer, which measures

the power of the engine with wonderful

exactness, consists of a generator

driven by the crank-shaft of the

engine. The pull exerted by the

revolving armature of the generator

against its movable magnetic field is

transmitted by levers to a scale which

indicates the force of the pull in

pounds and fractions on a dial. The

current from the electric generator is

absorbed in resistances or fed to the

regular line wires from a switchboard,

and may be used to drive other

machinery.

-

Lingua

-

eng

-

Data di rilascio

-

1919-06

-

pagine

-

45

-

Diritti

-

Public domain (Google digitized)

-

Archived by

-

Davide Donà

-

Marco Bortolami (editor)