How shoes and uniforms were shipped to France during World War I

Item

-

Title (Dublin Core)

-

How shoes and uniforms were shipped to France during World War I

-

Article Title and/or Image Caption (Dublin Core)

-

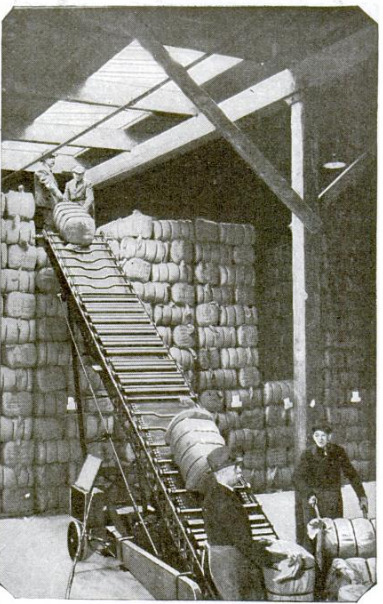

Save Money by Baling Your Clothes. Apply this lesson learned in the war

-

extracted text (Extract Text)

-

IF you are a manufacturer or

an exporter of clothing, it will

mean dollars and cents to you

to learn how the Quartermaster-

General's Department shipped

uniforms and shoes to France in

a way that saved the Govern-

ment eighty-five million dollars

in a little more than a year.

Few of us realize how desper-

ate was our need for ships at a

time when German submarines

were sinking six hundred thou-

sand tons a month. “Give us

ships, ships, and more ships,”

was the demand of those who

had to equip and feed our Army

in France.

In the autumn and winter of

1917-1918 it became apparent

that if the war was to last very

‘much longer there would not be

shipping space enough to carry

the equipment and supplies re-

quired by the forces that we in-

tended to send overseas. New

methods of shipping equipment

had to be invented, and the man

who invented them was Major

David T. Abercrombie, of New

York.

Compressing Twenty Cubic

Feet into Four

Clothing is usually shipped

in wooden packing-cases. But during

the war wood became scarce. Major

Abercrombie estimated that, 72,762,

800 feet of board lumber, 2,425 tons

of nails, and 404 tons of strapping

would be needed. The lumber re-

quired would have denuded 7,552

acres of timber-land—lumber that

could mot be grown again for thirty

years,

“We won't use packing-cases,” de-

cided Major Abercrombie,

“But what will you do?” they asked

him.

“Bale everything,” was the answer.

And that is how it came about that

the Government saved eighty-five

million dollars.

Major Abercrombie experimented,

and found that clothing could be

squeezed so that, roughly, twenty

cubic feet of material could be made to

oceupy four cubic feet of space. Con-

sider that ship tonnage is charged for

on a cubic foot basis, and that during

the war the rate was eight dollars per

cubic foot, and you can see at once

that by compressing twenty cubic feet

to four cubic feet a saving of ninety-six

dollars was at once effected. Then

consider that during the war

1,371,000 bales were shipped,

that the net saving on each

bale ranged from filty to

sixty dollars, and you can see

that the Government saved

eighty-five million dollars.

Major Abercrombie’s project

also released 8,180,000 cubic

feet of shipping space.

Major Abercrombie dis-

covered that proper baling

depends on the proper folding

of a uniform. Baling should

crease a uniform along the

right lines.

Folding the Garments

Scientifically

To carry out Major Aber-

crombie's process, the gar-

ment is first carefully folded

to a form. A given number

of folded garments are then packed

in a brick container, corded together

so that the bricks cannot fall apart.

The folded uniforms in their brick

container are then placed in a ma-

chine,

First of all, hand pressure is

applied to form a fairly compact

bale. But that bale is not com-

pact enough. for Major Aber-

crombie. It is subjected to the

additional squeezing effect of a

power baler until it assumes the

highly compressed form that he

has in mind.

Waterproof paper is used asa

lining for each bale. Major Aber-

crombie had to invent a paper of

his own—a creped waterproof

paper that would stretch thirty

per cent in one direction and ten

per cent in the other. Thanks to

that paper the bale becomes

absolutely waterproof.

-

Contributor (Dublin Core)

-

Michael Connors (writer)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1919-10

-

pages (Bibliographic Ontology)

-

62

-

Rights (Dublin Core)

-

Public domain (Google digitized)

-

Archived by (Dublin Core)

-

Davide Donà

-

Alberto Bordignon (Supervisor)

Popular Science Monthly, v. 95, n. 4, 1919

Popular Science Monthly, v. 95, n. 4, 1919