-

Titolo

-

The experiments made to improve the shipment of war supplies and the importance of their results for commerce in peacetime

-

Article Title and/or Image Caption

-

Can You Make a Crate that Won't Break? Some results of the Forest Products Laboratory's experiments in the testing of boxes, barrels and crates

-

extracted text

-

SHIPPERS have, within recent

years, rather been forced to the

conclusion that there is a science

and art in the building of shipping con-

tainers. Before the war this conclu-

sion was thrust upon them by the

mishaps that befell them in attempt-

ing to reach South American and other

foreign trade.

But during the war the idea crystall-

ized. It culminated in special activity

on the part of the Forest Products

Laboratory at Madison, Wisconsin—

a branch establishment of the United

States Department of Agriculture.

Here a school was brought into being

for the training of men having to do

with the packing and crating of

quantities of material sent overseas.

The tests made here, primarily

instituted to promote war efficiency,

have provided a fund of information

that will be invaluable to manufac-

turers and shippers in peace time.

The shipping departments of the

larger manufacturers have already

‘made tests and experiments of their

own. In fact, every package sent

out is an experiment. But the sub-

jeet is still dark and uncertain in a

great many of its aspects. So we

pass along the results of the Forest

Products Laboratory's experience

because of their special value in

contributing to the general fund of

knowledge on the subject.

What methods are followed in

this packing-box testing laboratory?

We may preface an explanation by

quoting D. L. Quinn, in charge of the

Madison Laboratory's work:

“A properly designed packing-box is

one which has enough strength in each

part for the purpose for which it is in-

tended. More than this, it should

‘have no more strength in any part than

is necessary to balance the average

strength in every other part. The,

data necessary for designing such a box |

cannot be obtained from observation of

boxes in actual commercial service, be-

cause the observer sees the box only

after it has completely failed. He docs

not seo the beginning of tho failures;

and he does not see, and consequently

cannot measure, the hazard which

completes them.

“A failure frequently bears evidence

in itself of the cause of the damage.

There is, however, no way of determin.

ing from a study of the failure the |

amount of force exerted by the damag-

ing cause. In cases where several

causes have been active, it is im

‘possible to identify each of them.” |

He concludes, therefore, that the |

immediate task of a testing laboratory

isto go at one thing at a time. That

is, the tests applied to containers

should be of such a nature that defects |

will be shown up singly, and

under such conditions that the

stress applied, and also the re-

sults, may be carefully checked

up and kept track of. By thus

measuring defects individually

and “pooling” the results, so to

speak, the tester will be able to

gain a comprehensive knowl-

edge of the all-around strength

of the box or crate, and its

probable capabilities when

in actual service.

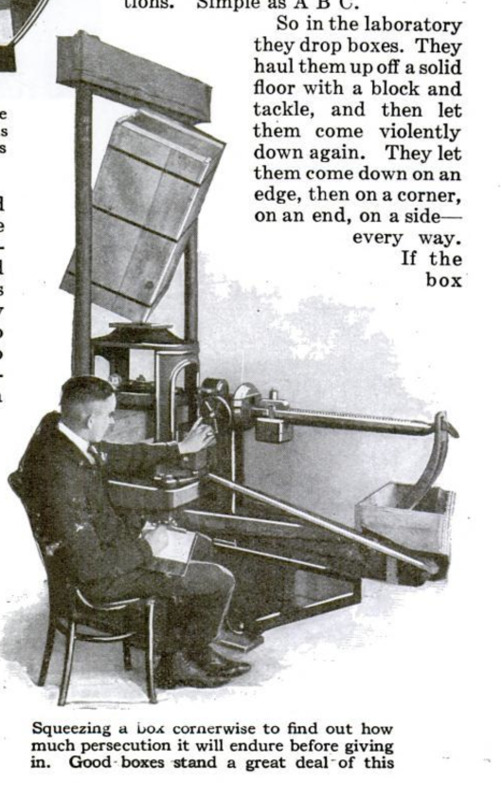

Initiating Tests

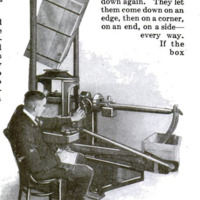

The “compression along

an edge” is one of the tests

applied. This consists in

standing a box upon one

edge and applying a steady

and constantly increasing

pressure to the diagonally

opposite edge. The longer

the box holds out against

such a squeeze, the better

box it is. Another box of

the same kind will be stood up on one

corner, and then pressure applied to

the opposite uppermost corner. The

longer the box holds out against this

"test, the better box it is. The il-

lustration at the bottom of this

page shows details of the process.

Another test applied to boxes in a

laboratory is to drop them. Simple,

isn't it? Even a youngster applies

that principle. If Amy Brown has

doll with a china head, and she de-

liberately drops the doll on a cement

sidewalk, and the head doesn’t

break—why, naturally, the doll is a

better one than Dorothy Smith's,

which does break under such condi-

tions, Simple as A B C.

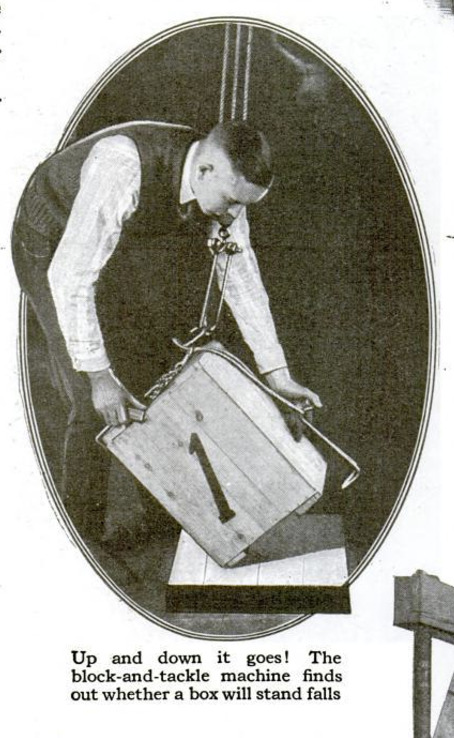

So in the laboratory

they drop boxes. They

haul them up off a solid

floor with a block and

tackle, and then let

them come violently

down again. They let

them come down on an

edge, then on a corner,

onan end, on a side—

every way.

If the

box

stands up under all that, it is a good

box and can be depended upon to

stand up under actual service; because

such man-handling as this is what the

box actually gets from the freight

rustlers and dock employees. The

testors reason that it is better to find

out in a laboratory whether a given

kind of box is no good for

its purpose than to find

out on the road, and per-

haps lose valuable goods in

the process. That this is

sound reasoning, is evident.

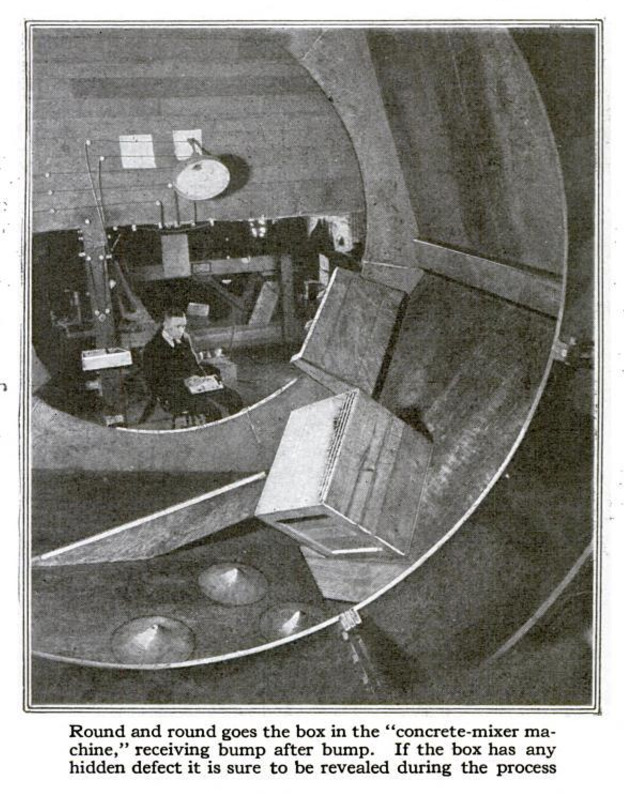

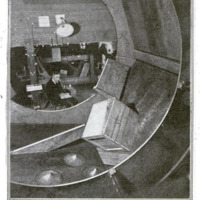

The Revolving Drum

A particularly choice

‘number in the repertoire of

the testing men is to run a

box through the revolving

drum apparatus. This looks

a good deal like a concrete-

mixer, only its drum is

larger. A box is put inside

the drum, then the drum +

proceeds to go round and

round in regular concrete-

mixer fashion. Meanwhile

the box is bumping around

among all kinds of pillars

and posts inside. When it

‘comes through this test—if

it does come through —it is

initiated indeed.

The drum revolves so

slowly that, as the box

drops from one projection

to the next, the beginning

of breaks and cracks can

be noted. The weak

points in the construe-

tion of the box will, of

course, readily make them-

selves apparent, and in the next box.

made along this line, the construction

can be altered in such a way as to avoid

defects of the kind that the test

brought out. By continually building

and testing in this way, boxes are

ultimately developed that are equally

strong in all features. Like the “one- |

hoss shay,” they will go to pieces all at

once, if they go to pieces at all. Their

failure will not be because of single

defects, such as nails pulled through

soft wood, or because ends of boards

split or broke off, or because the wrong

Tumber was used for that particular box |

inthe first place. The box constructor

will know what he is doing.

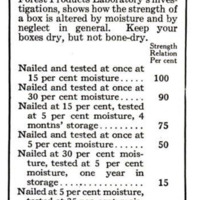

The laboratory has found that the

length of a nail, rather than its gage,

seems to be the principal factor in its

holding power. Since nails split wood,

it has been found that it is desirable

that as small gage nail be used as can

be driven by a nailing-machine. Mr.

Quinn finds that -standard cement

coated box nails seem to be most desir-

able from the standpoint of both

efficiency and economy.

“Nails,” says Mr. Quinn, “should be

driven flush with the wood. They

should never be over-driven. Over-

driving causes the heads to break the

fiber of the wood under them, often

to such an extent that no holding

power is loft in the wood. Tho first

strain on the box then causes the wood

to pull away from the nails. The evil

effect of over-driving nails naturally

Increases as the material In

the boards is made thinner.

But in any box over-driving

is bad practice, and should

be guarded against.

“The size of the nail to

“be used depends upon the

species and the thickness of

the lumber in which the

points of the nails are held.

With the woods white elm,

red gum, sycamore, pump-

kin ash, black ash, black

gum, tupelo, and soft or

silver maple, as well as hard

maple, beech, oak, hack-

berry, birch, rock efm, and

white ash, the penny of the

nail should be the same as

the thickness of the lumber

expressed in eighths of an

inch. The following woods

take the next penny

larger: white pine, Norway

pine, aspen, spruce, South-

ern ‘and Western’ yellow

pine, cottonwood, yellow

poplar, balsam fir, ‘chest-

nut, sugar pine, basswood,

cypress, willow, noble fir,

magnolia, buckeye, white

fir, cedar, redwood, butter

nut, cucumber, alpine fir,

lodgepole pine, hemlock,

Virginia and Carolina pine,

Douglas fir, and larch.

_“Sixpenny nails and smaller should

be spaced not more than two inches

apart when driven in the side grain of

the end, and not more than one and

three fourths inches apart when driven

inthe end grain. The spacing of nails

in end construction should be in-

creased from the above, one fourth

inch for each penny over six.”

More Facts About Nails

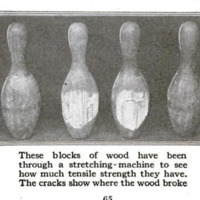

One hardly realizes the force it takes

to pull a nail out of a wooden board.

In experimenting with the holding

‘power of cement-coated, plain, and

barbed sevenpenny nails, driven

one inch into dry wood, Mr. Quinn

obtained the following facts:

Using a cement-coated nail, it

takes about a 225-pound pull to get

a nail out of one inch of longleaf

yellow pine, 133 pounds out of bass-

wood, and 430 pounds out of beech.

Plain nails took 140 pounds with

longleaf pine, 82 pounds with

basswood, and 400 pounds with

beech. Barbed nails required only

110 pounds with longleaf pine,

70 pounds with basswood, and 335

pounds with beech.

-

Autore secondario

-

Lloyd E. Darling (writer)

-

Lingua

-

eng

-

Data di rilascio

-

1919-10

-

pagine

-

64-65

-

Diritti

-

Public domain (Google digitized)

-

Archived by

-

Davide Donà

-

Alberto Bordignon (Supervisor)