The warping of aircraft propellers and how it is prevented

Contenuto

-

Titolo

-

The warping of aircraft propellers and how it is prevented

-

Article Title and/or Image Caption

-

Title: Stopping the Ariplane Propeller from Drinking Too Much

-

extracted text

-

DURING the war one of the great-

est troubles experienced with air-

plane propellers was the warping and

twisting of the blades near the tips,

and a large percentage of the propellers

received at the front were rejected on

this account.

In order to determine the causes and

to develop methods of preventing this

trouble, a number of experimental

propellers were manufactured for the

War and Navy Departments by the

Forest Products Laboratory of the

U. S. Forest Service, at Madison,

Wisconsin.

The propellers were made of Central

American and African mahogany, the

wood being carefully selected stock,

uniform in density and moisture con-

tent. They were stored under uni-

form atmospheric conditions for thirty

days between the roughing out and

final carving operations. After the

standard finish, consisting of five coats

of spar varnish, had been applied, they

were again stored under the same

conditions for observation us to warp-

ing and twisting.

Humidity Is the Bugbear

These propellers were made up and

handled much more carefully than the

commercial product, and every pos-

sible effort made to produce perfect

results. After exposure to a very

damp or humid atmosphere for three

or four months, it was found

that every propeller had

warped or twisted, or other-

wise changed shape, to an

extent that made them unac-

ceptable for use. They had

all absorbed about five per

cent of moisture through the

five coats of spar varnish, and

this moisture caused trouble.

The treatment to which these pro-

pellers were subjected, namely, being

manufactured under relatively dry

conditions and later exposed to moist

atmosphere, is very similar to that

which is normally received by pro-

pellers made in the United States and

shipped to France. Frequently pro-

pellers are made in a moist climate and

shipped to a drier one, and trouble

from change of shape due to drying

out, and consequent warping of the

wood, is almost sure to result.

“There are only two ways in which

trouble from change of shape due to

atmospheric conditions may be ob-

viated either make the propeller im-

mune from changes in humidity, or

keep it under the same atmospheric

conditions all its life. The experi-

ments just outlined show that it is im-

possible, even under ideal manufactur-

ing conditions, to produce propellers

that, if preventive measures are not

taken, will not warp or twist with

changes in moisture.

These changes may be prevented by

applying a moisture-proof coating.

At present, the aluminum leaf coating,

developed by the Forest Products

Laboratory, is the only practical

moisture-proof coating that has been

successfully applied to propellers. It

is not possible to keep propellers under

absolutely uniform atmospheric condi-

tions during manufacture and service,

but these conditions can be approached

by making up the propellers at the

moisture content which they will nor-

mally reach in service. Propellers

made up in this way and coated with

aluminum leaf, have the best possible

chance to give high efficiency and long

service.

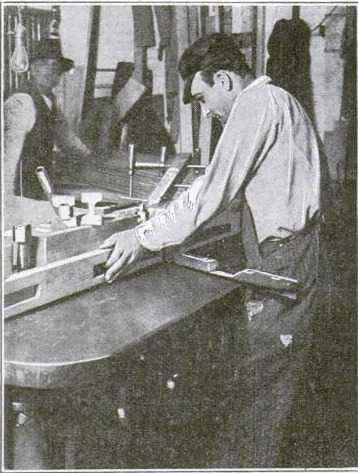

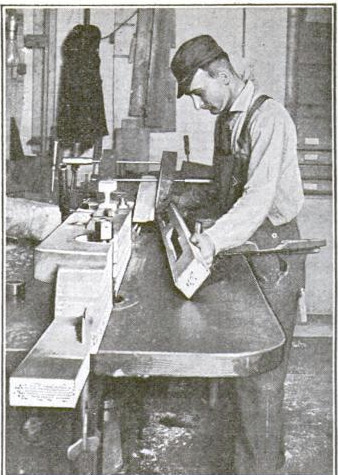

Testing the Propeller’s Strength

The wood of which the propeller is

made is always tested for strength. In

doing this the machine shown in the

diagrams used. The strut is put under

pressure and the load increased grad-

ually till the maximum is reached—

that is, until the load ceases to increase

deflection. Repeated experiments on

Sitka spruce and Douglas fir airplane

struts of various patterns have shown

that if stopped at this joint

the test does mot injure the

strut. The sketch illustrates

a simple machine by which

struts may be tested in this

way at the rate of one hun-

dred or more an hour.

After the experimental

beams have been constructed

in the carpenter shop of

the Forest Products Laboratory

they are delivered by truck to one of

the testing laboratories for a final

strength test. One of these beams is

show... undergoing test. The load is

applied at four points through the

lever system which is attached to the

cross-head of the testing machine.

‘The two screws are turned by means of

gearing, thus drawing down the ross-

head through which they are threaded.

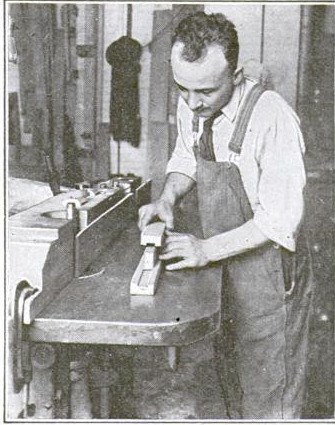

When a beam breaks it sometimes

shatters in a number of pieces and is

very apt to fly entirely out of the

testing machine. A broken beam is

shown in the foreground.

This particular machine was bor-

rowed from the Kansas State Agri

cultural College for the war emergency,

it being impossible to purchase a suffi-

cient number of machines from the

manufacturers. The results of many

tests indicate that the three-piece I-

‘beam is, under ordinary circumstances,

t0 all intents and purposes as strong

as, or even superior to, the solid I-beam

shaped out of one piece.

-

Autore secondario

-

Fred Gilman Jopp (Article writer)

-

Lingua

-

eng

-

Data di rilascio

-

1919-12

-

pagine

-

92, 94

-

Diritti

-

Public domain (Google digitized)

-

Archived by

-

Davide Donà

-

Marco Bortolami (editor)