-

Title (Dublin Core)

-

The Army Air Forces laboratory tests newly developed airscrews

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Proving ground for props

-

Subtitle: Newly designed airscrews undergo grueling tests at Wright Field, where delicate instruments show how they will withstand strains encountered in actual flying

-

extracted text (Extract Text)

-

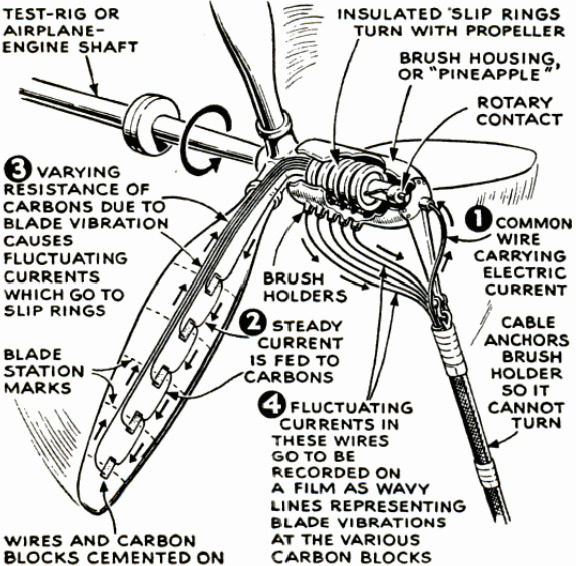

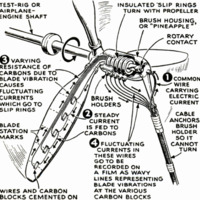

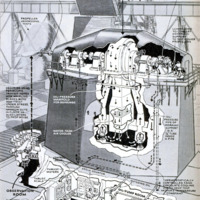

HOW will a propeller blade of new de-

sign behave when it whirls at full

speed through the air? Tiny oblong strips

of carbon, attached along its length, help

answer the important military question in

the great propeller-testing laboratory of the

Army Air Forces at Wright Field, Dayton,

Ohio. The laboratory has been designed and

built by, and is operated under direct charge

of, D. Adam Dickey, a civilian electrical

engineer, who has been cited for exceptional

performance by the Secretary of War.

Spun by electric motors ranging in speed

up to 4,300 r.p.m. and in power up to 10,000

horsepower, propellers as large as 16 feet

or more in overall diameter give up their

secrets. Bending and twisting, the blades

impart their strains to the telltale thin

carbon strips. And these, in turn, “telephone”

their report in the form of fluctuating elec-

tric current, just as do the carbon granules

in a telephone transmitter. The pulses cor-

respond to changes in the electrical re-

sistance of the carbon, according to the

degree of pressure upon it. On the propeller

blade, individual wire circuits lead from each

carbon strip down along the blade base and

hub to a fixed collector known from its

shape as a “pineapple.”

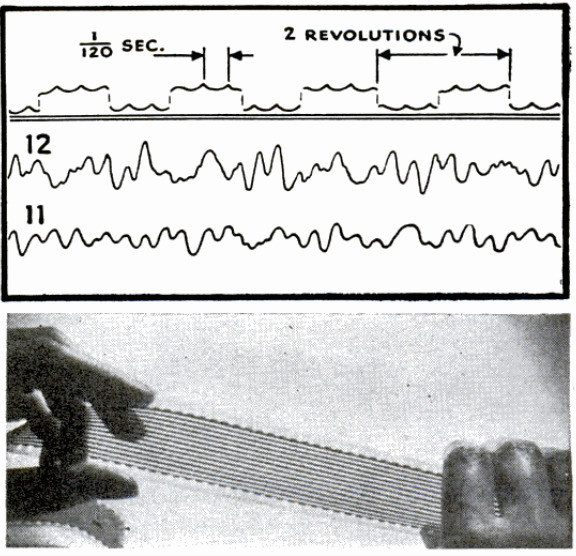

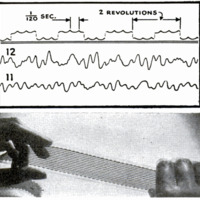

Much as sound traces are imprinted upon

motion pictures, current channels from the

collector simultaneously trace 12 parallel

lines on 35-mm. movie film. Upon develop-

ment, each vibration record is seen to be

an irregular wavy trace. Like the sound

trace of a symphony orchestra, it combines

‘many different vibrations. These may come

from the blade itself, its mounting, or its

gearing, and may include harmonic tones—

such as those heard from a musical. instru-

ment in addition to its fundamental pitch.

If gasoline engines are substituted forselec-

tric power, vibrations from cylinder ex-

plosions also enter into the record.

To unscramble this medley, the test film is

“played back” in a sound-analyzing room.

For audience, it has no human ears. In-

stead, a photoelectric-cell pickup silently

transmits impulses to an electrical analyzer,

a marvel of science believed to have no

counterpart in the world. Here the complex

vibration is broken down into its com-

ponents. Not only may an observer view

the results in glowing lines on the windows

of cathode-ray tubes, but a permanent

record also is made upon sensitized paper.

Thus the vibrations most important to re-

duce are traced to their source and corrected.

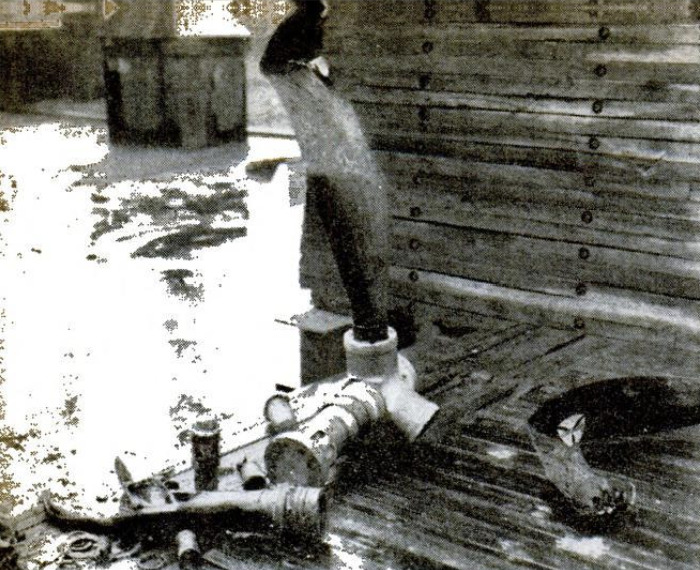

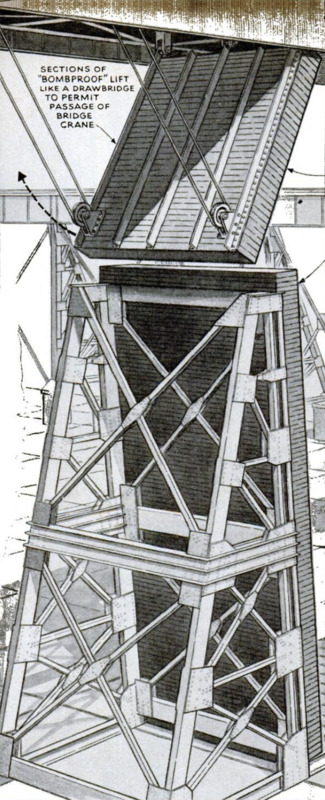

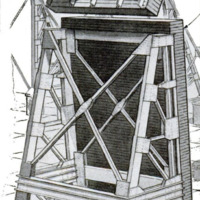

Safe in a tunnel roofed with steel I-beams

and heavy timbers, another observer watches

the propeller during the test, using a transit

as a periscope to sight through a slit in his

protective covering. Many a pilot would be

surprised, if not alarmed, to see blades that

he thought were rigid become flexible and

bend from their standstill

position. Actually this is per-

fectly normal. To find just

how much a propeller can

stand, it may be tested to

destruction, by running it at

much higher speed and load

than will ever be needed in

service. Since flying pieces

are thrown off in the plane of

the circular path of the pro-

peller, the safety walls may

be of very moderate width.

Once the breaking point is

found, engineers assure the

pilot a generous margin of

safety.

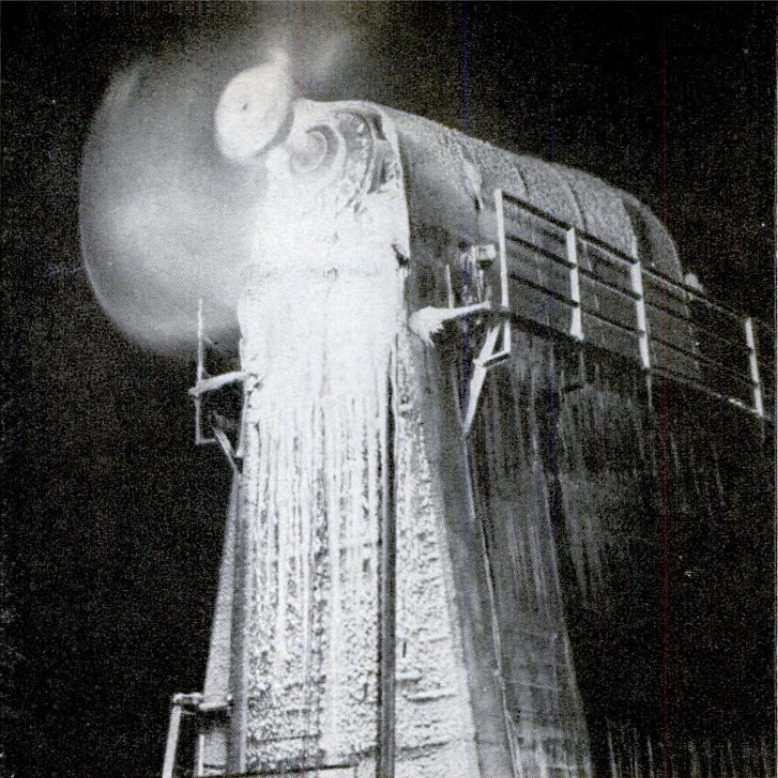

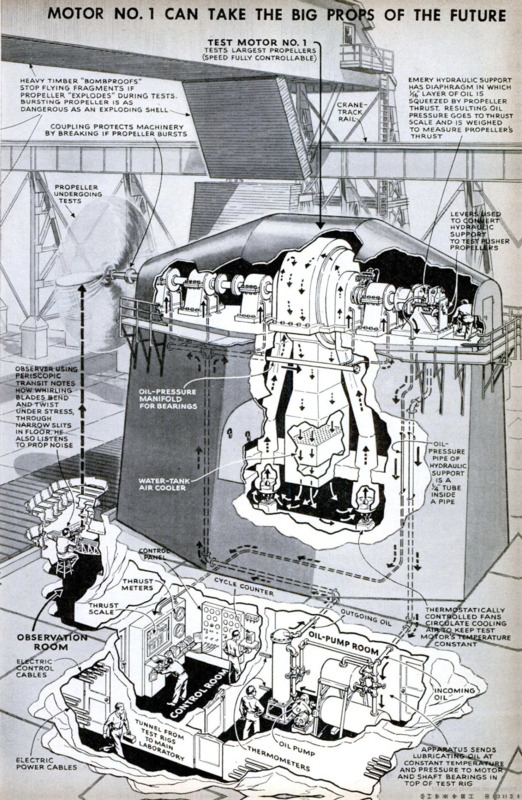

Behavior of a propeller in

rain, which nicks its leading

edges, and in icing weather,

which alters its curvature,

shows up in special tests.

How much pull or push a

propeller exerts — engineers

call it thrust—naturally is a

paramount consideration.

While electric meters meas-

ure the power delivered to the

motor, and a counter records revolutions

per minute, the propeller shaft bears

upon an Emery hydraulic cell through a

Kingsbury thrust bearing so that the

thrust is ultimately indicated by means

of a dial or weighed on a sensitive balance.

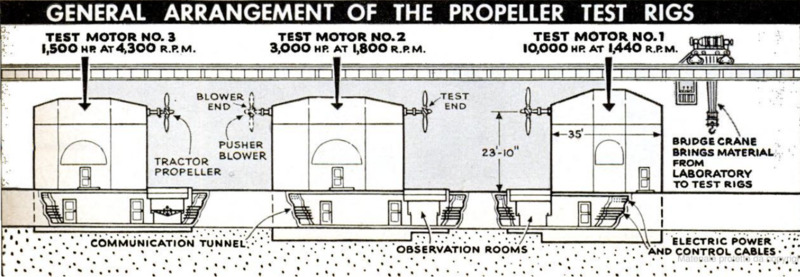

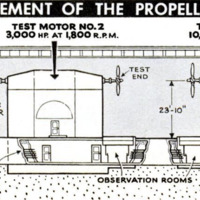

The three electric test stands of the

installation have been designed for both

present and future needs. An airship

propeller as large as 40 feet in diameter

could be tried out. And, despite the mighty

forces at play, precision governs.

When manufacturers submit competi-

tive models to suit new Government

specifications, the interests of the Air

Forces and fairness to the makers both

demand that the propellers must be

tested under precisely the same condi-

tions. Hence an elaborate system of

ventilating and lubricating, in each test

stand, maintains constant motor and oil

temperatures, with unvarying oil pres-

sure in the bearings throughout com-

parative trials. Allied airmen thus are

sure of getting the best that our fac-

tories know how to produce.—ALDEN P.

ARMAGNAC,

-

Contributor (Dublin Core)

-

Alden P. Armagnac (article writer)

-

Stewart Rouse (illustrator)

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1944-04

-

pages (Bibliographic Ontology)

-

66-69

-

Rights (Dublin Core)

-

Public Domain (Google digitized)

-

Archived by (Dublin Core)

-

Lorenzo Chinellato

-

Marco Bortolami (editor)

Popular Science Monthly, v. 144, n. 4, 1944

Popular Science Monthly, v. 144, n. 4, 1944