-

Title (Dublin Core)

-

Several kinds of explosives each one with its own particular job in war as in peace

-

Article Title and/or Image Caption (Dublin Core)

-

Title: Teaching explosives to do tricks

-

Subtitle: They're just fat-burning chemicals that pack a punch ... there are many kinds, and each kind has its own particular job to do in war as well as in peace

-

extracted text (Extract Text)

-

MODERN WARFARE is the art of using

explosives to throw explosives. In any

battle, the side which can throw the largest

quantity of explosives the greatest distance

and with the greatest speed usually comes

out the winner.

But what are these things we call ex-

plosives? Most of us think of them as

powerful, violent chemicals which go off

that is, explode—on the least provocation.

Actually, any explosive which meets this

definition is usually too sensitive for war-

time use. The best known of the high ex-

plosives, TNT, is so insensitive that it will

not explode even if hit directly by a high-

powered rifle bullet. As for power, there is

actually more energy in a pound of coal

than in a pound of TNT.

‘The secret of explosives lies in their con-

trol. They must be used in such a manner as

to release their power suddenly, at just the

right second and in just the right place.

With industrial explosives, the right time

means when everyone has moved out of the

danger zone around the explosion, and the

right place may mean that point in a bore

hole which will break away just the desired

amount of rock. With military explosives,

there are even more precise demands as to

time and place, for a shell must not explode

under the impact of firing it from a gun, but

it must explode at a predetermined second.

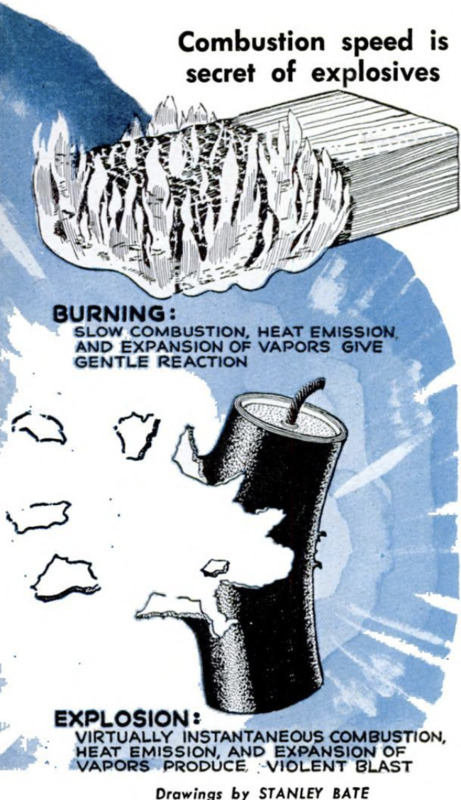

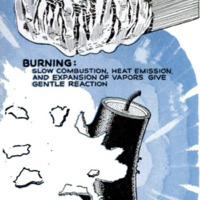

Actually, explosives are simply compounds

or mixtures which burn. But they differ

from ordinary burning things in two re-

spects; they burn much faster, and most

of them carry their own oxygen supply.

‘When you burn a piece of wood, its outer

surface combines with the oxygen in the

air, and a large part of the wood is trans-

formed into gases. In the reaction a great

deal of heat is released. If you used small

chips of wood, they would burn much faster

because they present more surface to the

air. And if you burned wood powder in

an atmosphere of pure oxygen, combustion

would be even more speedy. In fact, it

would take place so fast that you would

have a miniature explosion.

When you deal with regular explosives,

vou speed up the combustion still further,

because chemicals are present which release

oxygen and thus hasten the process. Most

of these chemicals are compounds of nitro-

gen and oxygen, for nitrogen is a “lone wolf”

element which separates readily from com-

bination with others.

Hundreds of fast-burning, or explosive,

compounds and mixtures are known, but

only a few can be used as military ex-

plosives. These are the ones which remain

inert until the proper moment and then

give off their energy under a controlled

impulse.

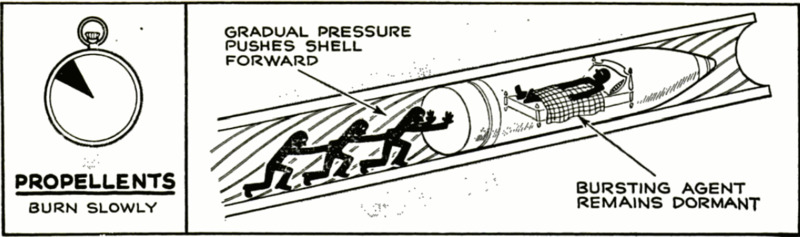

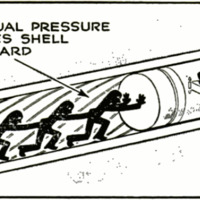

There are two basic types of military

explosives. Those called propellants are

relatively slow-burning and give off large

quantities of gas. When one of these is

exploded within the barrel of a gun, it builds

up its pressure gradually and thus does not

shatter the gun itself. Instead, it sets in

motion the one part of the assembly that

can be moved—the bullet or shell—and, as

the gases expand, this is guided by the gun

barrel and moves out to fly through space

toward the enemy. Of course, the so-called

slow burning of a propellant is slow only in

comparison with the rapid detonation of a

high explosive. Its burning actually occurs

in a fraction of a second.

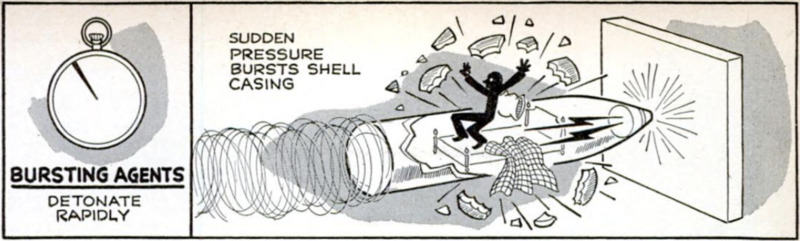

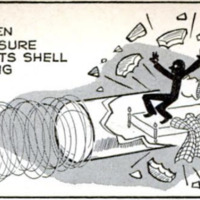

The second great class of military ex-

plosives consists of the bursting agents.

These are insensitive explosives capable of

withstanding the great heat and shock ex-

perienced within the shell when they are

hurled out of the gun barrel. But when they

finally do explode, the reaction takes place

50 fast that they shatter their steel con-

tainers and wreak havoc wherever they land.

While propellants explode by “burning,”

bursting agents explode by a process known

as detonation. The difference is merely one

of speed, but it is a great difference. Ordi-

nary smokeless powder burns in the open

air at a rate of three or four inches per

second. Inside a gun barrel, heat and pres-

sure speed up this rate very greatly. But

TNT detonates at a rate of over 22,000 feet

per second, and nitroglycerin has a detona-

tion speed of over fire miles per second!

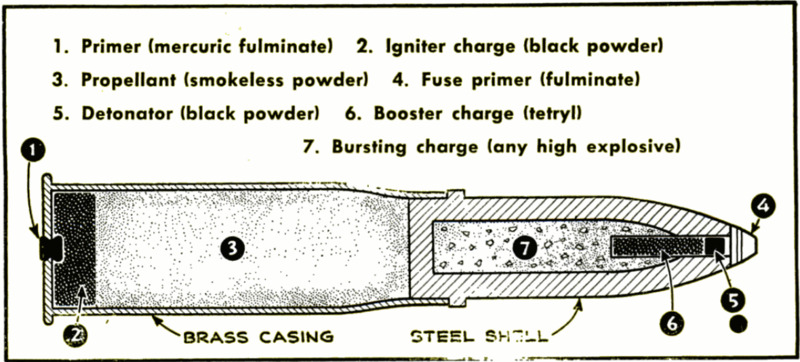

Both propellants and bursting agents,

however, are relatively insensitive. This is

an essential quality because otherwise they

would frequently explode in the manufactur-

ing plant, in shipment, or in an ammunition

dump. But in order to cause them to go off

at the proper time, ordnance experts have

had to develop other explosives known as

primers or detonators. These are sensitive

enough to explode from the shock of a ham-

mer blow or the percussion of a firing pin.

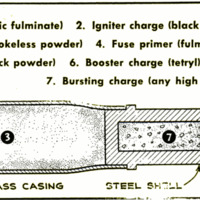

On small arms such as shotguns or rifles,

a tiny detonator is sufficient to initiate the

explosion of the smokeless powder in a shell.

But in larger cannon, a chain of explosions

frequently is necessary. The firing pin of

a big gun will detonate a small and sensitive

primer of fulminate of mercury. This will

in turn ignite a charge of black powder, and

this will pass on the explosion to the less

sensitive smokeless powder that hurls the

shell out of the gun and toward the enemy. |

The same sort of train is used within the |

shell itself. With an armor-piercing shell,

the artilleryman wants to be certain that the

projectile first pierces the enemy's protective

armor and explodes within the fortification

or the hull of a ship. He accomplishes this |

by equipping his shell with a delayed-action

fuse mechanism. The relatively insensitive

explosives within the steel shell actually

withstand the terrific shock of impact upon

armor. But this shock slows up the shell,

and causes a striker set in the back of the

shell to hit a tiny detonating charge. This

in turn may set off a booster charge and,

completing the sequence, the booster will set

off the high-explosive shell. Such a train |

of explosions can be designed to take any |

desired number of fractions of a second, or

even seconds or minutes.

Even though propellants are relatively

slow-burning, ordnance experts find it neces- |

sary to control their rate of burning. The

ideal explosion is one which will continue

with mounting force until the shell has left |

the gun. The pressure within the gun should

build up gradually so as not to shatter the

barrel; and none of the explosive should be

wasted by failure to be consumed before

the bullet has left the gun.

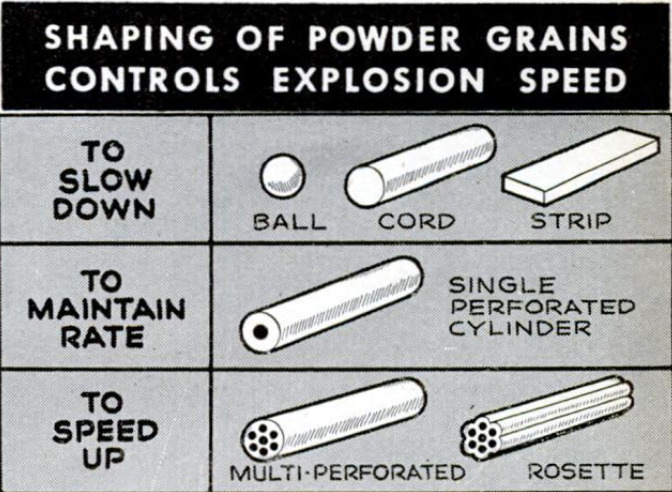

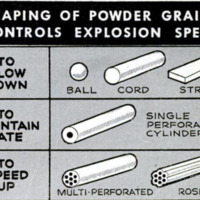

To control the burning of the propellant

powder, it is formed into grains. The larger

the caliber of the gun, the larger the grains

of powder which are used. Increase in size

slows up the burning, since the grains start

burning on their outer surfaces and com-

bustion progresses inward only as the outer

layers are consumed.

This method of slowing up burning pre-

sented the engineers with another problem.

Originally, all grains were formed in spheri-

cal ball shape. Thus, they burnt fastest at

the start of the explosion, when their outside

surfaces had the greatest area. As each

pellet burned away, it became a smaller

sphere and thus produced its gases at a

slower rate. Such round-grain pellets built

up high initial pressures, which quickly

dropped off. This didn't matter very much

with small arms, but it was a serious draw-

back when large guns were involved.

‘To overcome this difficulty, ord-

nance experts have developed a

number of different shapes for

powder grains. The British evolved

cordite, a smokeless powder in long,

cordlike grains. The French de-

veloped thin, flat strips. In Amer-

ica, engineers worked out still an-

other way of regulating the rate

of burning. They continued using

round pellets, but they coated them

with relatively slow-burning outer

surfaces. Thus, when the burning

surface was greatest in area, at

the beginning of the explosion,

these deterrent coatings slowed

down production of gases. Once the

outer surfaces of the sphere were

consumed, the faster-burning inner

powder compensated for the reduc-

tion in the area of the burning sur-

face. Such a powder grain would

be termed “balanced,” in that it

produced its gases at a fairly uni-

form rate,

But American engineers have

gone even further and developed “progres-

sive-burning” powder grains—forms that

increase their rate of burning as they are

consumed. This is accomplished by forming

the powder into cylinders with as many as

seven holes running through a cylinder,

parallel to its axis. While the outer surface

of the cylinder decreases in area as it burns,

the surfaces of the holes increase. Because

they are designed to more than compensate

for the decreased area of the outer surface,

they actually produce gases at an accel-

erated speed toward the last quarter of

their explosion.

With such powders, it has become possible

to design guns of high efficiency. Gun bar-

rels can be thinner than before, and still

withstand the pressures in the barrel, for

these pressures build up gradually and the

power of the explosion is not wasted in

“flash” after the shell has left the gun.

American engineers were also responsible

for the development of smokeless powders,

although these were first adopted by other

countries. Black powder, which had been

used from the earliest days until after the

Spanish-American War, had a number. of

drawbacks, not the least of which was the

fact that it gave off large quantities of

smoke which aided the enemy in locating

artillery.

Smokeless powders were made possible by

the development, toward the end of the nine-

teenth century, of nitrocellulose. They are

more stable, eliminating the greater part of

the muzzle flash and smoke formerly asso-

ciated with all firing pieces. However, they

are not completely smokeless, although

their small white puff is far less easily lo-

cated than the dense black smoke of the

powders formerly used.

Most armor-piercing shells depend ‘upon

steel rather than upon explosives to secure

their armor-piercing effect. Such shells are

made of extremely hard, tough, and heavy

steel, hurled at great velocity from long-

barreled guns. Large armor-piercing shells,

such as those designed to penetrate battle-

ship armor, are almost solid chunks of metal.

The weight of their high-explosive charge

can be only five or six percent of their total

weight. Yet, that five or six percent is

sufficient to cause terrific damage within

the close confines of an armor-plated hull

once the steel slug has penetrated.

Another method of armor piercing, which

has not yet been adopted by any warring

nation—except possibly in secrecy—involves

the use of what is known as the Munroe

effect. This phenomenon was first dis-

covered by Charles E. Munroe, professor of

chemistry at Columbian University, Wash-

ington, D. C., and was announced nearly 45

years ago in POPULAR SCIENCE MONTHLY.

Professor Munroe, in conducting his ex-

periments at the Naval Torpedo Station in

1888, noted that explosive waves tended in

certain cases to reinforce each other. His

discovery was made quite by accident.

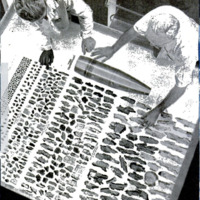

Professor Munroe used to mark blocks of

molded guncotton for identification by coun-

tersinking letters into the surface of the

blocks. When such blocks were laid upon a

steel plate and exploded, Dr. Munroe noted

that after the guncotton had detonated, the

letters were reproduced upon the iron plate.

What was most singular was that when

the letters on the guncotton were raised

above the surface they also came out raised

on the iron plate.

“In experimental investigation,” Dr. Mun-

roe wrote in POPULAR SCIENCE, “I eventually |

bored holes of various diameters and depths

in guncotton cylinders and in the last in-

stance, I bored a vertical hole completely

through the cylinder. These cylinders were

each placed on a similar iron plate. When

they were successively fired, it was found

that the deeper and wider the hole in the

guncotton was, the deeper and wider were

the holes produced in the iron plate. When

the completely perforated guncotton cylin-

der was fired, the iron plate was found to be

completely perforated.”

‘What Munroe had done was to shape an

explosive charge in such a way as to cause

the detonation waves to reinforce each other.

He concentrated much of the explosive force |

in one direction, parallel to the axis of the

cylinder. |

Conceivably, such shaped charges might

be used for armor-piercing purposes on

large shells, eliminating the necessity of

sacrificing ninety percent or more of an

armor-plercing shell to the weight of steel.

A shaped-charge shell would be almost en-

tirely made up of explosives, with only a

thin outer container of metal. Gunners using |

such a shell could deliver a far greater

quantity of explosives to a point of impact.

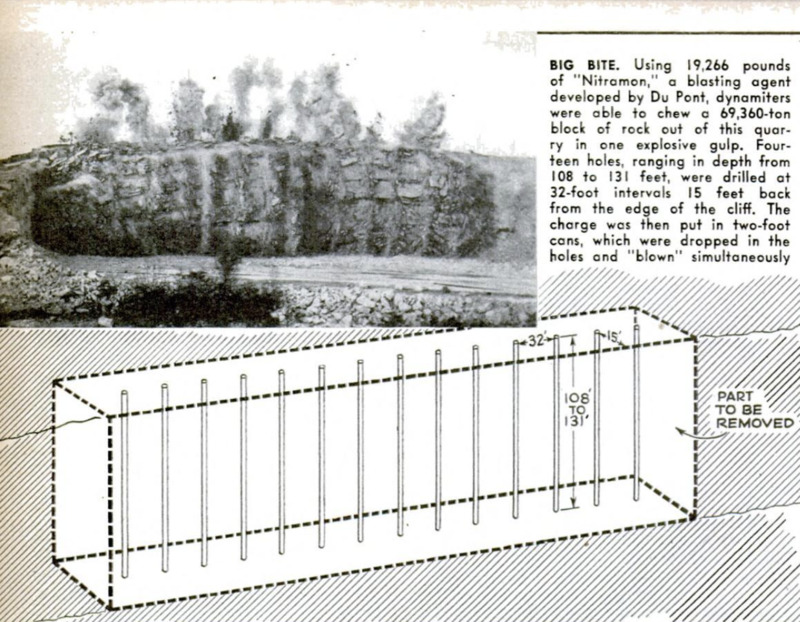

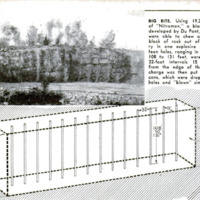

So-called industrial explosives—of which

dynamite is the best known and most widely

used—play an important part in the winning

of the war, both by making production

possible at home and in their application

on and immediately behind the battlefields.

Dozens of new and improved methods of

using such explosives have arisen directly

out of the war effort.

Dynamites have changed greatly from the

first product developed by the great Alfred

Nobel. Nobel made dynamite by absorbing |

highly explosive nitroglycerin in an inert |

earth called kieselguhr. This made a power-

ful explosive which was still sufficiently

insensitive to shock to permit its being |

transported and stored without great danger.

Today, instead of kieselguhr, dynamite

makers use mixtures of wood pulp, nitrate |

of soda, nitrate of ammonia, and other com-

pounds’ to absorb the basic nitroglycerin. |

By varying these materials, they can control |

both the sensitivity and the power of their |

dynamite and, at the same time, control |

fumes which will remain after detonation.

Such control is very important in preventing

accidents in underground mining.

Gelatin dynamites, containing nitrocotton

dissolved in the nitroglycerin, are highly |

water-resistant and can therefore be used |

for underwater blasting. In the old days,

many accidents were caused by attempting

to thaw frozen dynamite at open fires.

Today, antifreeze chemicals are mixed

into dynamite to eliminate this problem.

-

Language (Dublin Core)

-

eng

-

Date Issued (Dublin Core)

-

1944-05

-

pages (Bibliographic Ontology)

-

128-133

-

Rights (Dublin Core)

-

Public Domain (Google digitized)

-

Archived by (Dublin Core)

-

Lorenzo Chinellato

-

Federico Mazzini (supervisor)

Popular Science Monthly, v. 144, n. 5, 1944

Popular Science Monthly, v. 144, n. 5, 1944

Immagine 2022-05-05 142344.png

Immagine 2022-05-05 142344.png Immagine 2022-05-05 142401.png

Immagine 2022-05-05 142401.png Immagine 2022-05-05 142418.png

Immagine 2022-05-05 142418.png Immagine 2022-05-05 142448.png

Immagine 2022-05-05 142448.png Immagine 2022-05-05 142546.png

Immagine 2022-05-05 142546.png Immagine 2022-05-05 142602.png

Immagine 2022-05-05 142602.png Immagine 2022-05-05 142620.png

Immagine 2022-05-05 142620.png Immagine 2022-05-05 142633.png

Immagine 2022-05-05 142633.png Immagine 2022-05-05 142647.png

Immagine 2022-05-05 142647.png Immagine 2022-05-05 142702.png

Immagine 2022-05-05 142702.png