-

Titolo

-

Can We Fly at 50.000 Feet?

-

Article Title and/or Image Caption

-

Can We Flight at 50.000 Feet? Dragging his planes to ever higher levels, man encounters deadly enemies in cold and low air pressure...can science conquer the stratosphere?

-

extracted text

-

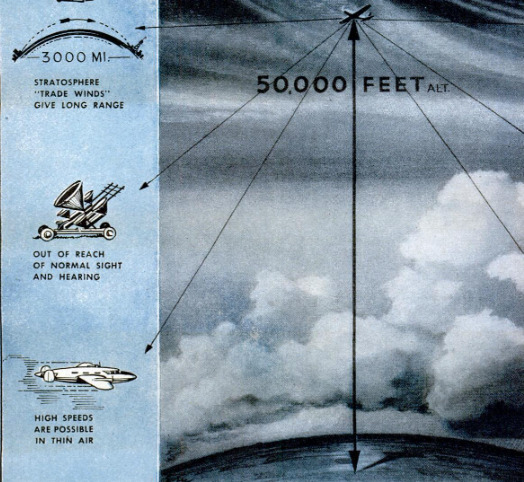

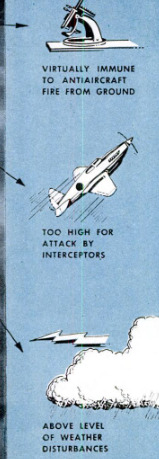

MODERN military air operation has es-

M tablished certain advantages for high-

level flying. The first, of course, is virtual

immunity from antiaircraft fire. Another is

freedom from interception, because the

higher the airplane flies, the greater the

time lapse before intercepting aircraft can

climb to the level of the high-flying ship.

At 40,000 feet, the true air speed of a ship

is twice that of the same ship at sea level;

the upper winds are steady and reliable,

and, once charted, can be depended on,

month in and month out, to be there as an

aid to operation. Furthermore, because

virtually all the weather phenomena occur

in the troposphere, or lower level of the air,

conditions in the upper levels are constant

and reliable.

For the same reasons, many long-visioned

planners of postwar air lines are looking

forward to the development of high-altitude

equipment for long-range travel in the days

ahead.

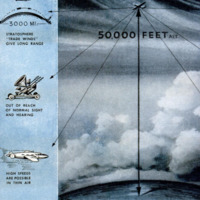

The 50,000-foot level, from an operational

viewpoint, looks like an attractive place to

fly. The weather is, for all practical pur-

poses, constant, varying only a little with

latitude. Above the level beginning at

around 36,000 feet, the air is perfectly dry;

the temperature is almost constant at -55

degrees C. (67 F.). The barometer, which

normally stands at 760 mm. of mercury on

the ground at sea level, reads 87.30 mm. at

50,000 feet—or .1518 the weight of normal

air.

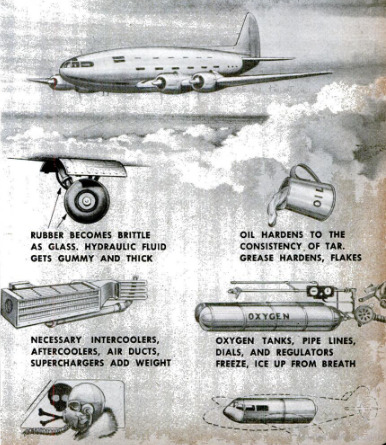

Man and his flying machine are intruders

at that altitude, and nature treats them as

such. The machine must carry heavy and

cumbersome equipment to supply its engine

with enough air to burn fuel needed |

to stay on the wing. Man himself is |

like the proverbial “fish out of water,”

and must surround himself with as

close to a synthesis of ground condi-

tions as possible in order merely to

stay alive.

When man was satisfied to call 20, |

000 feet high altitude, his problems

were comparatively simple. Warm clothing

solved the problems of adequate body heat;

bottled oxygen solved his air problems. The

major questions were mechanical—getting

the engine to produce enough power to keep

the airplane in flight in the thinned-out air.

Both man and motor suffer from reduced

air pressure. The motor is given more oxy-

gen by feeding it forced air (supercharg-

ing); man is supercharged by his oxygen

equipment. As the ship sought more alti-

tude and the application of superior super-

charging made higher ceilings possible, both

man and the airplane were beset by a multi-

tude of problems stemming from the de-

crease in temperature and pressure.

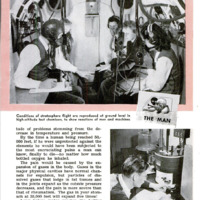

By the time a human being reached 50,-

000 feet, if he were unprotected against the

elements he would have been subjected to

the most excruciating pains a man can

know, finally to die—no matter how much

bottled oxygen he inhaled.

The pain would be caused by the ex-

pansion of gases in the body. Gases in the

major physical cavities have normal chan-

nels for expulsion, but particles of dis-

solved gases that lodge in fat tissues and

in the joints expand as the outside pressure

decreases, and the pain is more severe than

that of rheumatism. The gas in your stom-

ach at 35,000 feet will expand five times!

Long before water reaches the boiling

temperature, the dissolved gases are ex-

pelled. The higher the altitude, the lower

the boiling point. At the same time, many

of the body fluids are less dense than water

and have a much lower boiling point. By

the same token, these liquids would sur-

render their dissolved gases at a much lower

temperature. The temperature of the human

body, however, is' substantially constant

(98.6 degrees F.). The increase in altitude

brings the gas-expelling level of these fluids

and the body temperature into dangerously

close proximity.

Before the war began, Transcontinental

and Western Air, Inc., put into service the

Boeing Stratoliner, a_ high-altitude, over-

weather ship which incorporated a sealed

and pressurized cabin which would retain

troposphere pressure conditions at high

levels, permitting ordinary flight comfort at

high altitudes. This ship was not for strato-

sphere flight, but flew the substratosphere

and decreased altitude effects by about

8,000 feet when operating at its top level.

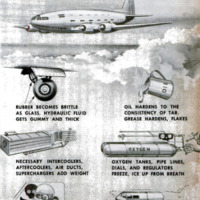

The first problem to be solved in the busi-

ness of high flight was that of engine super-

charging. Naturally, when one left the

greater part of the atmosphere below, the

engine would feel the effects of oxygen

starvation long before the pilot. Super-

chargers are simply rotary compression

pumps that provide sea-level air to the en-

gine at higher altitudes. Dr. Sanford Moss

gave mankind the key to stratosphere fly-

ing when he designed the exhaust-driven

turbo-supercharger toward the end of the

last war. However, it opened the way for

a multitude of subsidiary problems. For in-

stance, the heat resulting from extra com-

pression necessary at extreme altitudes is

0 great that special cooling apparatus must

be used to reduce temperature. These “in-

tercoolers” and “aftercoolers” used with

high-altitude supercharger equipment add

to weight, bulk, and complication.

The coefficient of expansion of aluminum

1s about twice that of steel. At ordinary

temperatures, this difference would be too

small to warrant serious consideration.

However, when the temperature drops to

67 degrees F., the tiny difference mounts.

Multiplied by the 67-foot length of the typi-

cal four-engine transports fuselage, the

difference is manifested in the slacking of

control cables. Particularly at high alti

tudes, this lost motion can be dangerous.

The first step in solving this problem

was the installation of a tension gauge on

control lines, so that adjustments could be

made manually. Currently, research is be-

ing conducted to determine what method—

wprings, hydraulic cylinders, _ete.—would

adequately take up this free play without

giving the pilot another detail to worry

about in the stratosphere.

The stratosphere itself should be its own

best research laboratory. In theory, the

best way to find out whether something

will work at 40,000 or 50,000 feet is to take

it up there and find out. That is the way

the earliest pioneers tried it, and the ex-

perimental trail is littered with their bones.

A recent example of this realistic testing

was the parachute jump from 40,200 feet

made by Lieut. Col. William Randolph Love-

lace near Euphrata, Wash, on June 24. The

35-year-old chief of the Aero-Medical Lab~

oratory at Wright Field, Dayton, Ohio,

wanted to make a personal test of bail-out

oxygen equipment for high altitudes de-

veloped under his supervision. Although he

tad never jumped

before, he made the leap—one of the highest

on record—with no mishap beyond a frozen

hand.

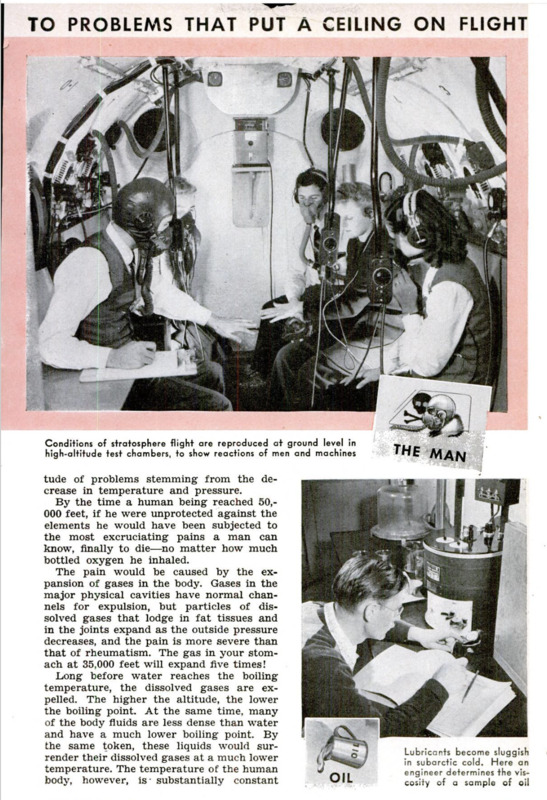

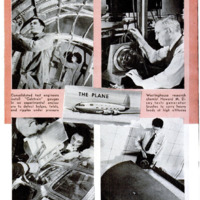

Now, scattered over the nation, in the

plants of major aircraft companies, in col-

leges, or at military and Government re-

search plants, are special wind tunnels, cold

chambers, and low-pressure chambers Which

can synthesize high-level conditions so that

we can explore the mysteries in comfort

and safety.

One of the newest of these is the 600-

mph. wind tunnel now being built at the

Army Air Forces’ major experimental sta-

tion at Wright Field. It is to be 600 feet

long, shaped like an “0.” A 40,000-hp. elec-

tric-motor system will drive fans capable of

whipping up a 600-m.p.h. controlled gale.

The rapidly moving air will be sped through

cooling coils in which are circulated tons of

calcium chloride solution chilled to —40 de-

grees F.

To make stratosphere tests, models are

placed in a steel compartment in the throat

of the tunnel. An airtight door is sealed and

the alr is pumped out to simulate strato-

sphere conditions.

A pressure cabin in a stratosphere plane

is like a deep-sea bathysphere, working in

reverse. Its job is to keep the life-giving

pressure inside. Unlike the bathysphere, it

must be pierced in several places to allow

control cables to pass through from the

pilot's rudder and control column to the

ailerons, rudder, and elevator. The problem

has tentatively been solved by a system of

glands. In some cases, the cable may have

to pass in and out of the cabin several times.

Each of these offers a new opportunity for

the precious sealed air to escape. This prob-

lem is currently being investigated by Con-

solidated-Vultee in their high-altitude re-

search department.

There still are a number of things we do

not know about how metals will act under

conditions of extreme cold. In metal mono-

coque structure, now widely used in aircraft,

an important consideration is the yield

point, or degree of stretching and bending

that a particular metal will take and still

return to its original size and shape. Effi-

cient design calls for the use of materials

whose yield point is close to their ultimate

strength.

Windows and transparencies ae neces-

sary in high-altitude bombers, and they will

be required in the transports of the future.

‘How will transparent plastics act in the ex-

treme cold, with pressure on the inside and

virtually none without? Rohm and Haas,

pioneers in plastic resins, have recently

opened a plastics research laboratory at

Bristol, Pa., to solve some of these prob-

lems. Part of the equipment is a supercold

room where temperatures can be dropped

below stratosphere level and engineers,

working in electrically heated suits, can test

plastics for impact and pressure under all

temperatures.

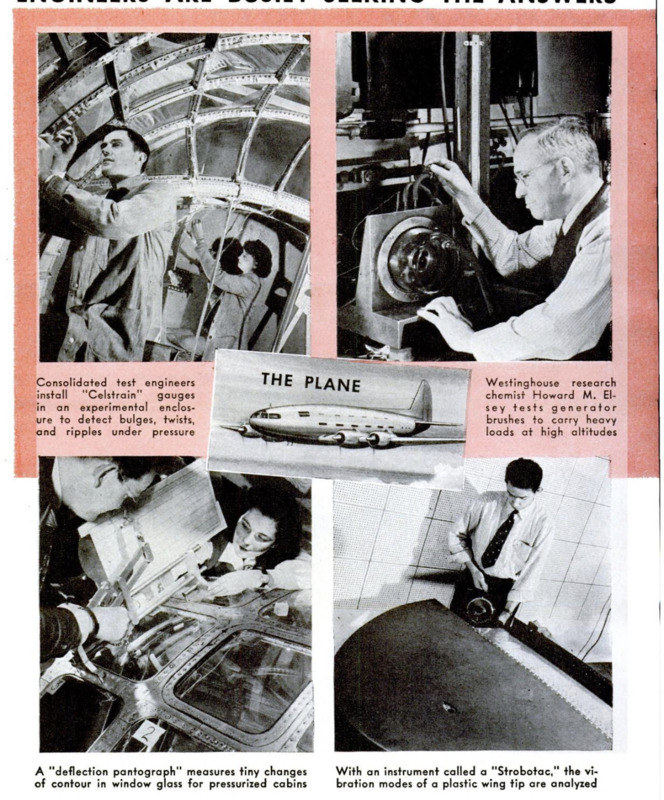

Of course, the structure of stratosphere

cabins themselves is subject to considerable

test. It is essential that engineers know

what is happening to the surface of the

pressurized cabin as the ship climbs, and

the difference in pressure inside and outside

the cabin is manifested in a bulging effect.

To determine this, Celstrain gauges, tiny

assemblies of strain-sensitive wires, are fas-

tened to points where the structure tends

to be weak, such as around windows. The

gauges, in giving the changes in resistance

to electrical current in proportion to the

strain exerted, tell the engineer how the

structure is behaving at various pressures.

Windows, being made of a less highly

stressed and flexible material, are an engi-

neering weak spot. To determine how glass

will act under sudden changes of tempera-

ture and pressure, specimens are mounted

on pressure boxes and examined by polar-

ized light. The underside of the glass is

aluminized.

‘The more complicated the airplane be-

comes, the more equipment there is to be

run electrically. This adds to the drain on

the airplane's battery and generator sys-

tem. Up to a certain point, the airplane's

own generating system, driven by a spur

from the main engines in the accepted auto-

motive manner, was sufficient. With the ar- |

rival of pressurized cabins, electric cowl

flaps, etc., the burst strain possible on the

reserve was so great that it was possible

to burn out the brushes in the generator in

a few minutes. Average operational life at

30,000 feet was a couple of hours.

Westinghouse Research Laboratories re-

cently offered a solution to this problem in

the form of new chemically treated brushes

composed of porous carbon impregnated

with a lubricant which films between the

brush and the swiftly rotating commutator.

Their use allows a burst overload, eliminat-

ing, in many cases, the need for auxiliary

generators,

One by one, the problems of the conquest

of the stratosphere are being solved. |

-

Autore secondario

-

William S. Friedman (writer)

-

Lingua

-

eng

-

Data di rilascio

-

1943-10

-

pagine

-

60-64, 212, 214

-

Diritti

-

Public Domain (Google digitized)

-

Archived by

-

Matteo Ridolfi

-

Alberto Bordignon (Supervisor)