Making Artillery Shells

Contenuto

-

Titolo

-

Making Artillery Shells

-

Article Title and/or Image Caption

-

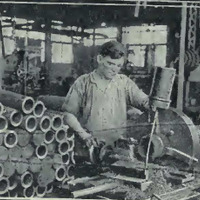

Making Shells for Europe - America's New Industry Which Keeps the Big Guns Barking

-

Caption 1: Steel point castings, "nose pieces," as they are received at the ammunition plant. A shell is composed of two pieces, the nose piece or point, and the body piece. The nose of the finished shell can be unscrewed from the body

-

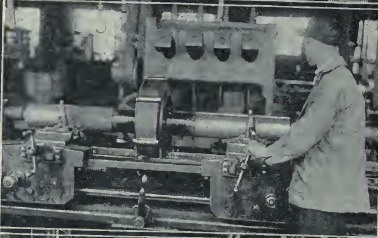

Caption 2: A twin machine that automatically turns two shell bodies at the same time to the right diameter. The shells being made are six inch explosive shells, used in the smaller naval guns and in field pieces

-

Caption 3: Truing up a six-inch shell after the body and point have been fitted together. This is careful work as the Allies are most critical and throw aside any shell which does not measure up to within one-two thousandth of an inch

-

Caption 4: Shaping the nose piece to fit the body of the shell. Note the measuring instruments at the worker's left. These are constantly used to guide him in making the nose piece absolutely accurate. The machine is of American make.

-

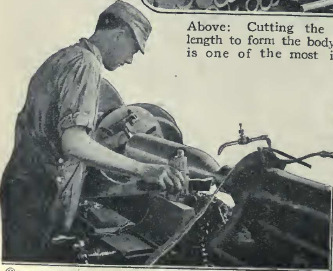

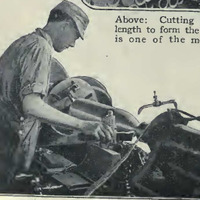

Caption 5: Cutting the forging the proper length to form the body of the shell. This is one of the most important operations

-

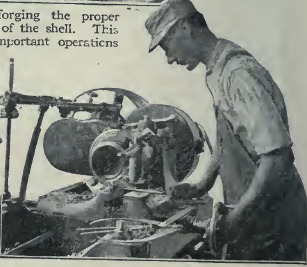

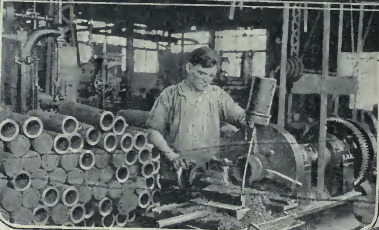

Caption 6: Boring the interior of a shell body to make the thickness of the body the proper dimension. Many different sizes are made, varying from one and four-tenths to sixteen inches, but the medium sizes are in greatest demand.

-

Caption 7: A pile of rough forgings from which the six-inch shells are made. The shells shown here would last but a few minutes in one of those fierce offensives that were daily occurrences in the early autumn fighting and before Verdun

-

Caption 8: After inspection each shell is given two coats of yellow enamel paint to prevent rust in transit. The shells are hanging by holes drilled in the nose piece. When ready to load, the nose is unscrewed with the aid of these holes

-

Caption 9: Testing the fitting of nose piece to the shell body. The rings shown on two of the shell bodies are for checking the outside dimension of the shells and the gage-stick shown in the third is used to get the depth of the bore

-

Autore secondario

-

Press Illustrating Serv. (photos)

-

Lingua

-

eng

-

Data di rilascio

-

1917-03

-

pagine

-

330-331

-

Diritti

-

Public domain

-

Archived by

-

Besleu Dinu

-

Alberto Bordignon (Supervisor)