-

Titolo

-

The importance of nitrogen in war and in peace

-

Article Title and/or Image Caption

-

Title: Nitrogen in War and in Peace

-

Subtitle: It helped to make the world safe for democracy and it keeps us from starving

-

extracted text

-

NITROGEN, the most democratic

of all the elements, is the es-

sential factor without which

the war for democracy could not have

been won. In the last analysis, war is

an effort to discover which of two

sides can liberate the most nitrogen

where it will do’ the greatest damage.

For all explosives are nitrogen com-

pounds —their deadly effects the result

of the ineradicable tendency of this

liberty-loving gas to burst its honds

and hurl in every direction fragments

of whatever has served to restrain it.

From old-fashioned black powder to

the most modern and powerful trini-

trotoluol, or “T.N.T.,” nitrogen is the

basis of them all.

Even more essential, in peace, is the

possession of nitrogen in usable form.

Without its aid there could be no

plant growth, nor could animal life

upon this globe continue. Yet, while

nitrogen is literally as common as air,

since four fifths of the volume of the

earth's atmosphere is free nitrogen

(serving to dilute the essential oxygen

and make it breathable, so that you

would not be literally burned alive), the

problem of obtaining sufficient nitro-

gen is one that holds the serious, even

apprehensive attention of scientists,

economists, and the Government itself.

Before the world became densely

populated with people who live in

cities, and who therefore depend upon

the annual crops produced by others for

their food, instead of living on the

fruits, nuts, and game that were the

food of our ancestors, nobody worried

about nitrogen. People went where

food could be obtained; if they failed

to arrive soon enough they starved.

When the World Faced Starvation

Up to less than a hundred years ago,

the entire human race was constantly

menaced by the possibility of famine

and wholesale starvation, and nature's

methods of supplying nitrogen to

plants through the action of bacteria

in the soil long ago became too slow

to keep pace with the increasing de-

‘mand of the human race for food.

For a great many years the world has

been dependent for its supply of nitro-

gen for fertilizer upon enormous depos-

its of sodium nitrate, or Chile saltpeter,

found in the high, arid desert regions

of Chile and Peru and nowhere else.

In late years there has been an ime

portant addition to this diminishing re-

source—the production of ammonium

sulphate as a by-product of the coking

of coal. But the total annual supply

from both of these sources, about

2,600,000 tons from each, is still in-

sufficient to meet the growing demand

for agricultural purposes alone, while

the war's demands created a situation

little short of critical.

Crookes’ Advice to Chemists

Twenty years ago Sir William

Crookes, then president of the British

Association, startled us by declaring

that the population of the world was

increasing so much faster than its

food supply that the race would soon

face starvation unless new means of

increasing the earth's fertility were

found. His words carried conviction,

and his suggestion that chemists turn

their attention to the development of

practical artificial means of extracting

the nitrogen of the air and “fixing”

it in usable compounds stimulated

experiment in that direction.

As a laboratory experiment, the

fixation of atmospheric nitrogen was

old. The main essential of all processes

then known, tremendously high tem-

peratures, running up even to 6,000°F.,

made the practical application of any

of them doubtful. Chemists, how-

ever, set to work. The development

of hydro-electric power at Niagara

and elsewhere, which made it possible

to produce high temperatures through

the electric arc, turned attention to

this’ means of accomplishing the

result sought. Charles S. Bradley, an

American engineer, almost at the time

Sir William Crookes was pointing out

the imminent need, began the first

large-scale experiment at Niagara Falls,

His process was not a commercial

success, but a little later a plant was

established at Notodden, Norway,

where, water-power costs only $3 a

year per horsepower. There nitrogen

Products were successfully made.

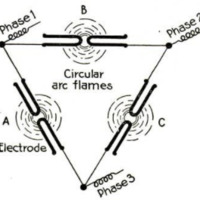

Reducing Nitrogen from the Air

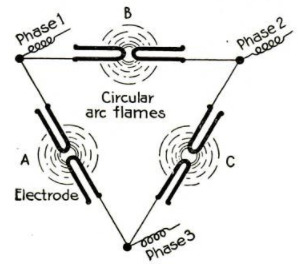

The process used at Notodden and

later at several other plants in Norway,

known as the Birkeland-Eyde, is not

unlike that devised by Bradley. An

electric arc js produced by leading a

current of about 5,000 volts equatori-

ally between the poles of an electro-

magnet. This produces what is prac-

tically a disk of flame six and a half

feet in diameter and having a tempera-

ture of about 3,000° F. The disk

really consists of a series of successive

arcs which increase in size until they

burst. Air is passed through this arc.

The first, product of the reaction is

nitric oxide, which, on cooling with

the residual gases, produces nitrogen

peroxide. The cooled gases are then

led into towers, where they meet a

stream of water coming in the opposite

direction. Thus nitric acid is formed

in the towers, in diminishing degrees

of dilution. In the last tower the re-

‘maining gases are brought into contact

with milk of lime, which combines

with the gases to form calcium nitrate

and nitrite. The nitric acid obtained

in the other towers is combined with a

base to form a commercial compound.

These Norwegian plants were fi-

nanced by Germany, and their output

of fixed nitrogen was almost entirely

absorbed by that country. At the

beginning of the war the annual

production of the Norwegian plants

was equal to about 10,000 tons of

fixed nitrogen a year. At that time

Germany imported annually 880,000

tons of nitrate of soda, equal to 137,000

tons of nitrogen. At the beginning of

the war Germany had a stock of

1,000,000 tons of nitrate, equivalent to

156,000 tons of nitrogen, and a by-

product ammonia capacity of 550,000

tons of sulphate of ammonia, equiv-

alent to 113,000 tons of nitrogen.

It is known that the Norwegian

plants have not been commercially

successful. In Germany several other

processes for the fixation of atmos-

pheric nitrogen were developed, all

of which helped to supply the enor-

mous quantity of nitrogen products

required in manufacturing explosives.

One of these processes, developed

by two German scientists, Drs. Frank

and Caro, who began their experi-

ments in 1898, is known as the cyana-

mid process. ' It is based upon the

fact that caleium carbide, largely pro-

duced as a source of acetylene gas, may

be induced with comparative ease to

absorb nitrogen, thus forming a com-

bination of calcium, carbon, and nitro-

gen, known commercially as eyanamid.

‘This is the only process that has been

installed on the American continent,

a plant in Canada, at Niagara Falls,

having been in operation for several

years, with an annual capacity of

about 60,000 tons.

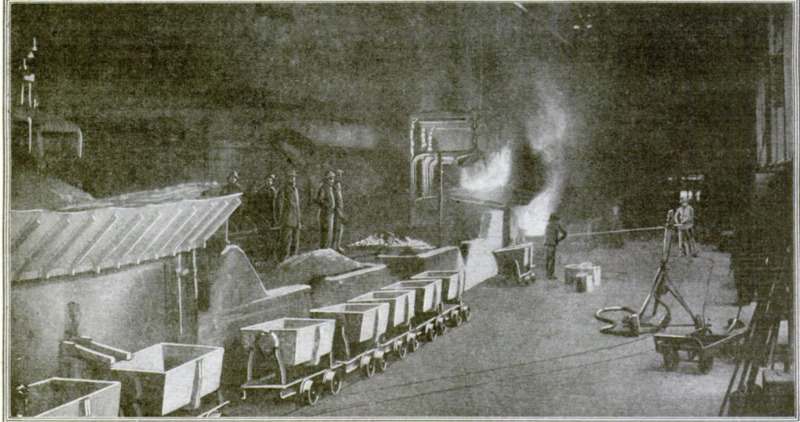

Production of Cyanamid

Thecarbideisplaced in the furnace and

the reaction is initiated by local resist-

‘ance heating to a temperature of 1500°-

2000° F., the conversion proceeding

to completion without further heating.

The nitrogen is obtained from liquid

air, manufactured by compressing air

to a density of 500 pounds to the square

inch and cooling by expansion. When

the liquid air begins to rise above its

normal temperature of —313° F., pure

nitrogen boils off. The compound of

calcium carbide and nitrogen, known

commercially as cyanamid, is itself

valuable as a fertilizer; by treatment

with superheated steam its nitrogen

may be released to enter into combina-

tion with the steam, forming am-

monia. In Germany about 600,000

tons of cyanamid is being produced

annually.

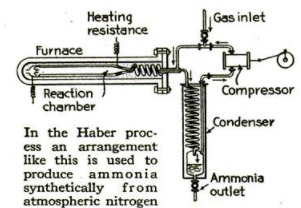

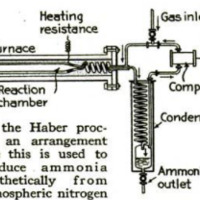

The other process of fixing atmos-

pheric nitrogen, on which Germany

mainly relies, is the Haber process.

In this, nitrogen and hydrogen gases,

under a pressure of 1,500 pounds to the

square inch, are passed through a

chamber electrically heated to a tem-

perature of 1,170° F. As a result, the

nitrogen combines with the hydrogen

to form ammonia. Although this

process has long been in operation in

Germany, its technical details have

been carefully guarded, and it took

chemical and electrical experts em-

ployed by the United States Govern-

ment nearly a year to discover its

secret from patents obtainedgin this

country.

The Haber Process

The Haber process involves the

‘presence of what is known in chemistry

as a “catalyst.” It has

been found that certain

elements or compounds

— the list is constantly

being enlarged —have

the remarkable prop-

erty of causing other

substances to com-

bine chemically, often

in entirely new for-

mations, without

themselves under-

going any change or

entering into the new

combination. A fa-

miliar example is the

common device for

lighting gas without

matches, which con-

sists of a small bit of “spongy plat-

inum,” or asbestos, fibers coated with

platinum black. When this is held

over an open unlighted gas-burner,

the presence of the platinum causes

the hydrogen in the gas to combine

with the oxygen in the air with

such speed and violence that great

heat is generated by the reaction, the

spongy platinum becomes incandes-

cent, and in a second or two is so hot

that the gas ignites.

In the Haber process the catalyst

is spongy iron, although any one of

several other substances probably

would answer as well.

In the electric arc process the first

produet is nitric acid, which is directly

usable for explosives. In the cyana-

mid and Haber processes the ammonia

product is best adapted for use as

fertilizer, but is readily convertible

into nitric acid by passing a mixture

of ammonia and air through a red-hot

platinum screen acting as a catalyst.

The fact that nitrogen can be fixed

directly in the form of sodium cyanide

by the action of nitrogen gas on a

mixture of soda and coke has been

known for many years; but, while

English, German, and American scien-

tists have tried their hands on a com-

mercial adaptation of this reaction, it

is only recently that an American firm

has been able to prepare sodium

cyanide for the market by this process.

A Low-Temperature Process

Intensive study of the various meth-

ods of speeding up the reaction has led

to the adoption of special apparatus,

and, at a temperature around 1800° F,,

with the assistance of a specially de-

veloped catalyzer, an unusually pure

cyanide is formed. From the cyanide

it is easy to prepare ammonia quanti-

tatively.

One advantage of this sodium cya-

nide method of fixation, aside from the

low temperatures used,

is that when ammonia

is made from the cya-

nide, another product

of commercial value is

also obtained—sodium

formate. This latter

material can be used as

a starting-point for a

number of artificial fla-

voring oils, for a whole

line of useful solvents,

or for making the for-

mic and oxalic acids

that are so necessary

in our dyeing processes;

for instance, and which

were formerly imported,

chiefly from Germany.

-

Autore secondario

-

Frank Parker Stockbridge (Article author)

-

Lingua

-

eng

-

Data di rilascio

-

1919-01

-

pagine

-

39-41

-

Diritti

-

Public domain (Google digitized)

-

Archived by

-

Davide Donà

-

Marco Bortolami (editor)